Gallium nitride lateral transistor with AlGaN/GaN heterojunction and manufacturing method of gallium nitride lateral transistor

A lateral transistor and heterojunction technology, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, electrical components, etc., can solve the difficulties of AlGaN/GaN heterojunction transistors, etc., and achieve the effect of improving performance and reducing peak electric field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

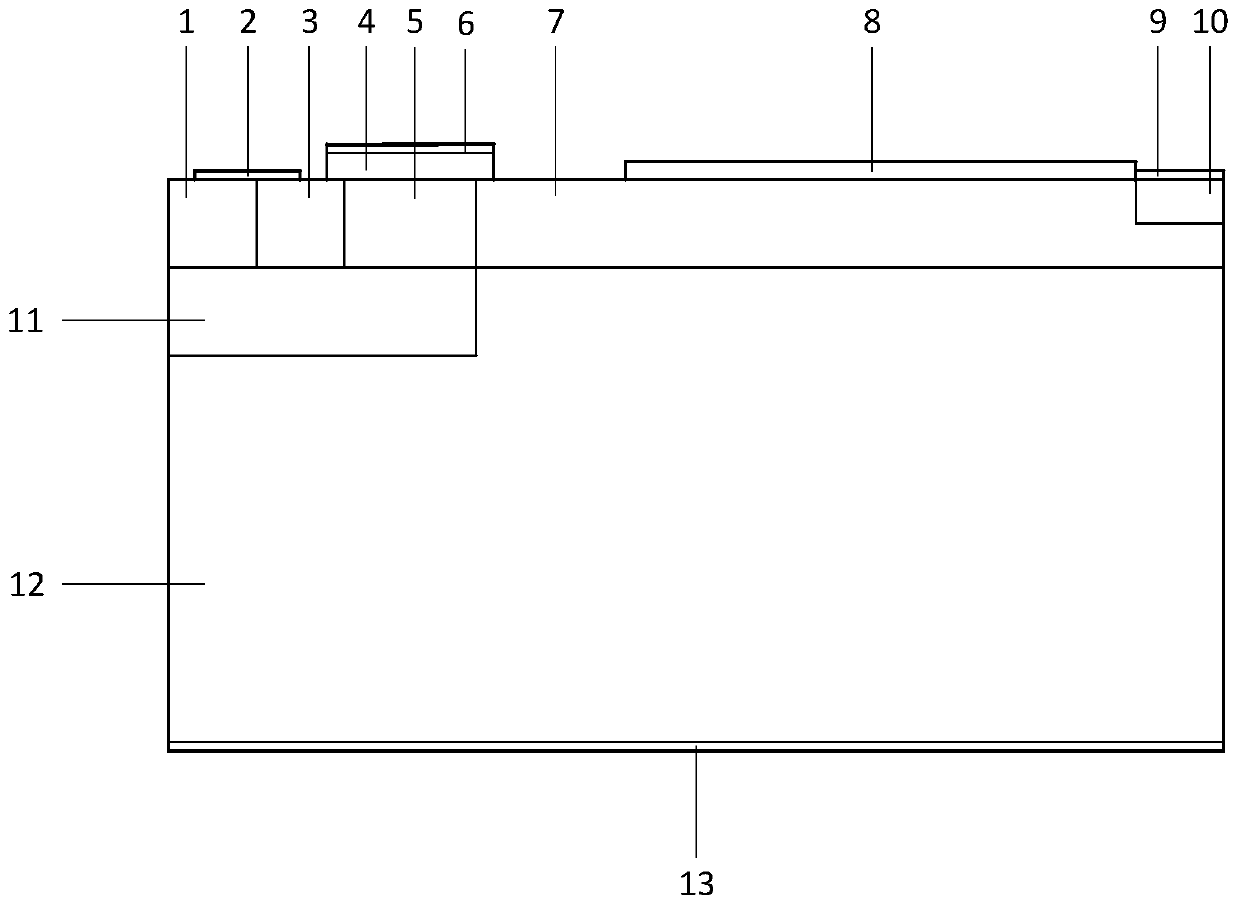

[0036] The present invention will be described below by taking a novel gallium nitride lateral transistor with an N-channel AlGaN / GaN heterojunction as an example in conjunction with the accompanying drawings.

[0037] Such as figure 1 As shown, the structure of this embodiment includes:

[0038] Substrates of semiconductor materials;

[0039] a drift region located on the surface of the substrate;

[0040] A base region, a source region, and a channel substrate contact formed by ion implantation based on one end of the drift region; the surface of the base region is covered with a gate dielectric layer;

[0041] A drain region formed by ion implantation based on the other end of the drift region;

[0042] Wherein, the substrate is a P-type GaN material, and the drift region is an N-type GaN material; a P-type shielding layer is also formed by ion implantation at the base region, the source region, and the substrate below the channel substrate contact;

[0043] The surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com