COB package and preparation method thereof

A technology for mounting parts and LED chips, applied in climate sustainability, semiconductor devices, electrical components, etc., can solve problems such as thermal failure of the light conversion layer, achieve mass production, simple packaging steps, and improve thermal failure and temperature too high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

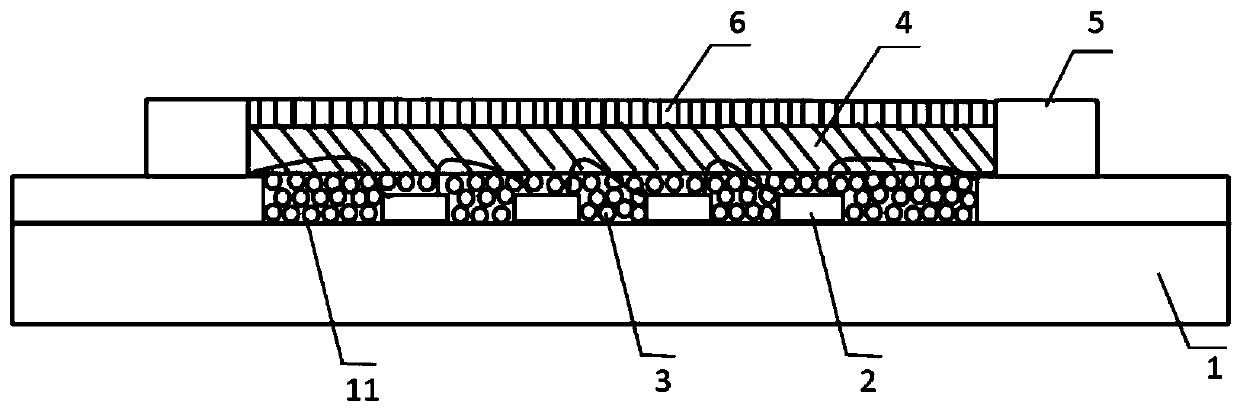

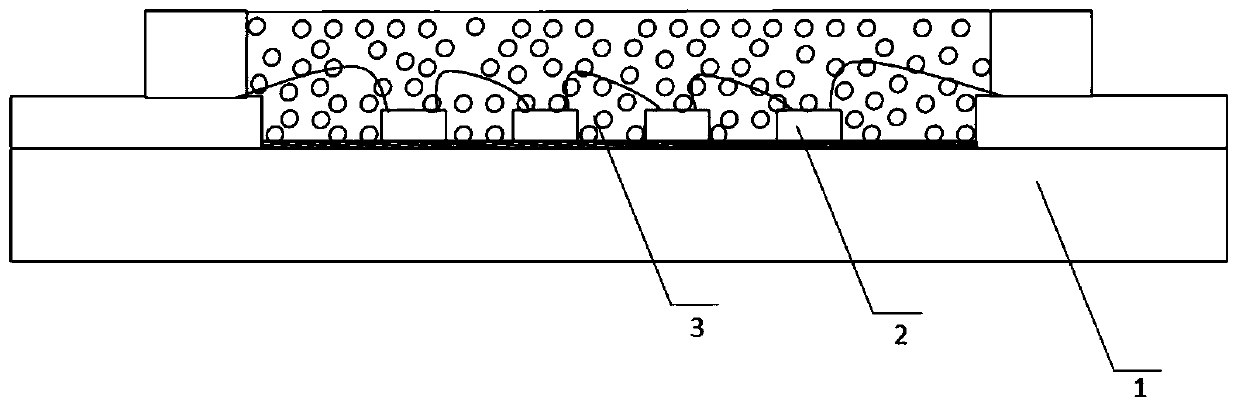

[0053] refer to figure 1 , a COB package, including a substrate 1, an LED chip 2, a light conversion layer 3, a silica gel layer 4, an adhesive barrier 5 and an outer protective layer 6; the substrate 1 is provided with a recessed installation part 11; the depth of the depression of the installation part 11 is 0.3mm; LED chip 2 is fixed in the mounting part 11; light conversion layer 3 covers LED chip 2; silica gel layer 4 is stacked on the top of light conversion layer 3; glue blocking 5 extends upward from substrate 1 and is arranged around silica gel layer 4 The light conversion layer 3 includes methyl silicone rubber; the silicone layer 4 includes methyl silicone rubber; the refractive index of methyl silicone rubber is 1.42, and the hardness is 50shoreA; the outer protective layer 6 is stacked on the top of the silicone layer 4; the outer protective layer 6 Including phenyl silicone rubber; the refractive index of phenyl silicone rubber is 1.5, and the hardness is 65shore...

Embodiment 2

[0058] The COB package of Example 1 is prepared by the following method:

[0059] LED chip fixing step: fix the LED chip in the mounting part of the substrate, and electrically connect the LED chip with a gold wire;

[0060] Steps for forming glue stop: dot coating on the periphery of the LED chip to form a stop glue, the height of the stop glue is 0.5mm, the function of the stop glue is mainly to prevent the light conversion layer from flowing out when filling;

[0061] Light conversion layer filling steps: fill the light conversion layer to cover the LED chip, generally the maximum thickness of the light conversion layer is 0.45mm, and then place it horizontally for 3 hours; the levelness requires ±0.1°;

[0062] Silicone layer filling steps: fill the silicone layer inside the rubber barrier and above the light conversion layer;

[0063] Degassing and baking steps: After filling the silica gel layer, perform defoaming treatment, and then bake, baking in stages: the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth of depression | aaaaa | aaaaa |

| Emission wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com