Lithium battery liquid injection system and lithium battery liquid injection method

A liquid injection and liquid injection technology for lithium batteries, which is applied in the manufacture of battery pack components, non-aqueous electrolyte batteries, and electrolyte batteries, etc., can solve the problems of low capacity, time-consuming, short life, etc., and achieve efficient liquid injection , prolong the service life and improve the safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

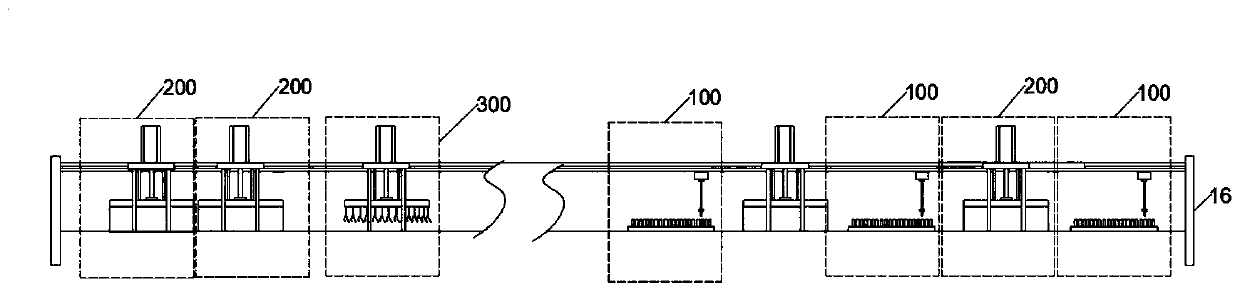

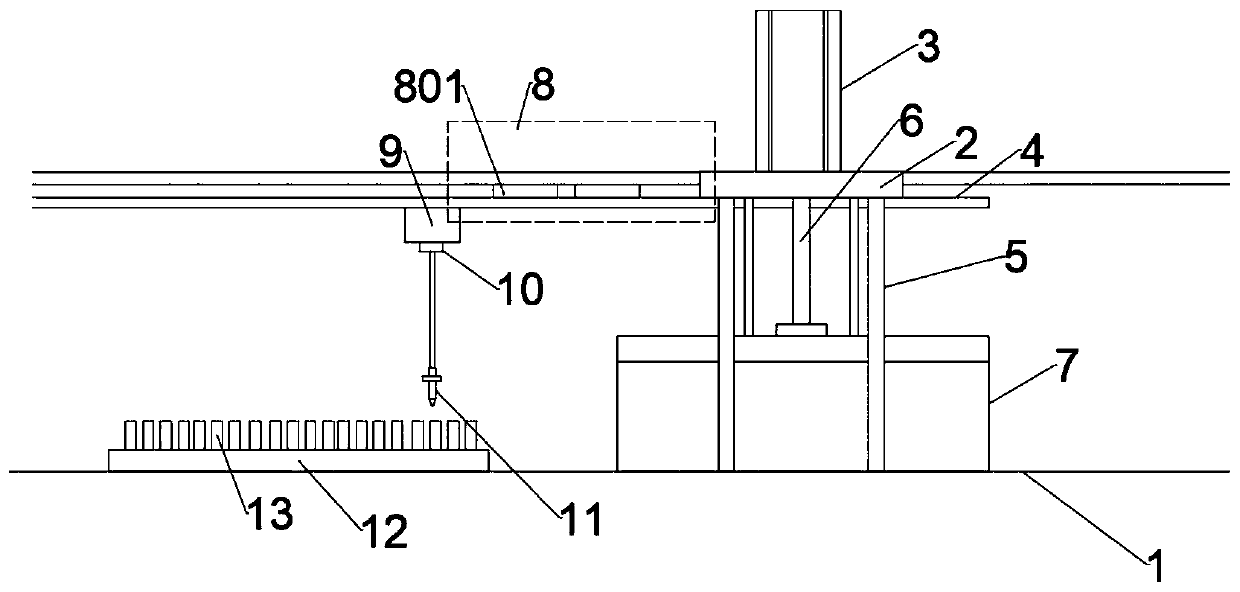

[0046] like figure 1 , 2 As shown, a lithium battery liquid injection system includes a conveyor and a work frame 16 for fixing the conveyor. The system also includes a liquid injection device 100, a charging device 300, and a vacuum device 200. The conveying of the conveyor Trays 12 are placed at intervals on the belt 1; a number of battery cells 13 are placed on the tray 12;

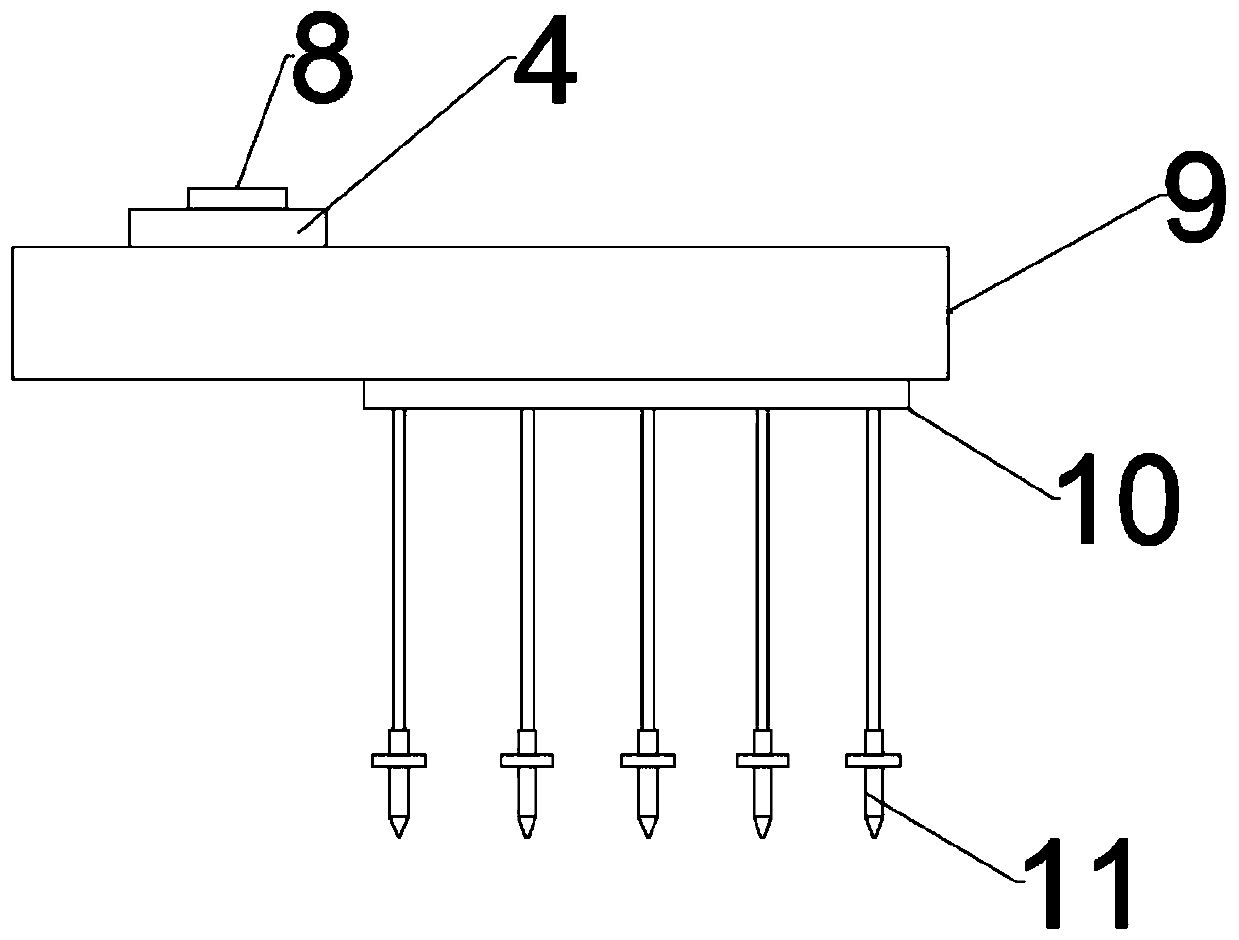

[0047] like image 3 , 4 As shown, the liquid injection device 100 includes a liquid injection frame 9, and a moving mechanism is fixed below the liquid injection frame 9 through a connecting block 901. The moving mechanism includes a moving screw 902, and one end of the moving screw 902 is connected to a motor 903. The mobile screw rod 902 is threadedly connected with a moving frame 10, and the moving frame 10 is connected with several liquid injection heads 11, and the liquid injection heads 11 are connected to the liquid injection pump through a hose, and the inlet end of the liquid injection pum...

Embodiment 2

[0058] like Figure 8 Shown, a kind of liquid injection method of lithium battery comprises the following steps:

[0059] S0: Equipped with the lithium battery liquid injection system of Embodiment 1, the specific implementation is not limited to the liquid injection system of Embodiment 1;

[0060] S1: one-time liquid injection: place the battery cell 13 in the tray, use the liquid injection device 100, and start injecting liquid into the battery cell 13, and the liquid injection volume is 15% of the capacity of the battery cell;

[0061] S2: One-time vacuuming: start the conveyor, transport the battery cell 13 after the first liquid injection to the position corresponding to the vacuuming device 200, start the vacuum pump, and perform one-time vacuuming. The vacuum pressure value is -20Kpa, and keep for 30s;

[0062] S3: Secondary liquid injection: the conveyor continues to transfer the battery cell after the primary vacuum to the liquid injection device 100 for secondary l...

Embodiment 3

[0076] like Figure 8 Shown, a kind of liquid injection method of lithium battery comprises the following steps:

[0077] S1: One-time liquid injection: place the battery cell in the tray, use the liquid injection device, and start injecting liquid into the battery cell 13 with the liquid injection head 11, and the liquid injection volume is 15% of the capacity of the battery cell;

[0078] S2: One-time vacuuming: start the conveyor, transport the battery cell 13 after the first liquid injection to the position corresponding to the vacuuming device 200, start the vacuum pump, and perform one-time vacuuming, the vacuum pressure value is -25Kpa, and keep for 40s;

[0079] S3: secondary liquid injection: the conveyor continues to transfer the battery cells 13 after primary vacuuming to the liquid injection device, and the liquid injection head 11 performs secondary liquid injection, and the liquid injection volume is 20% of the capacity of the battery cells;

[0080] S4: Seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com