Systematized treatment module of kitchen waste

A technology for processing modules and kitchen waste, which is applied in animal husbandry, solid waste removal and other directions to achieve the effects of high space utilization, convenient transportation and large breeding volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

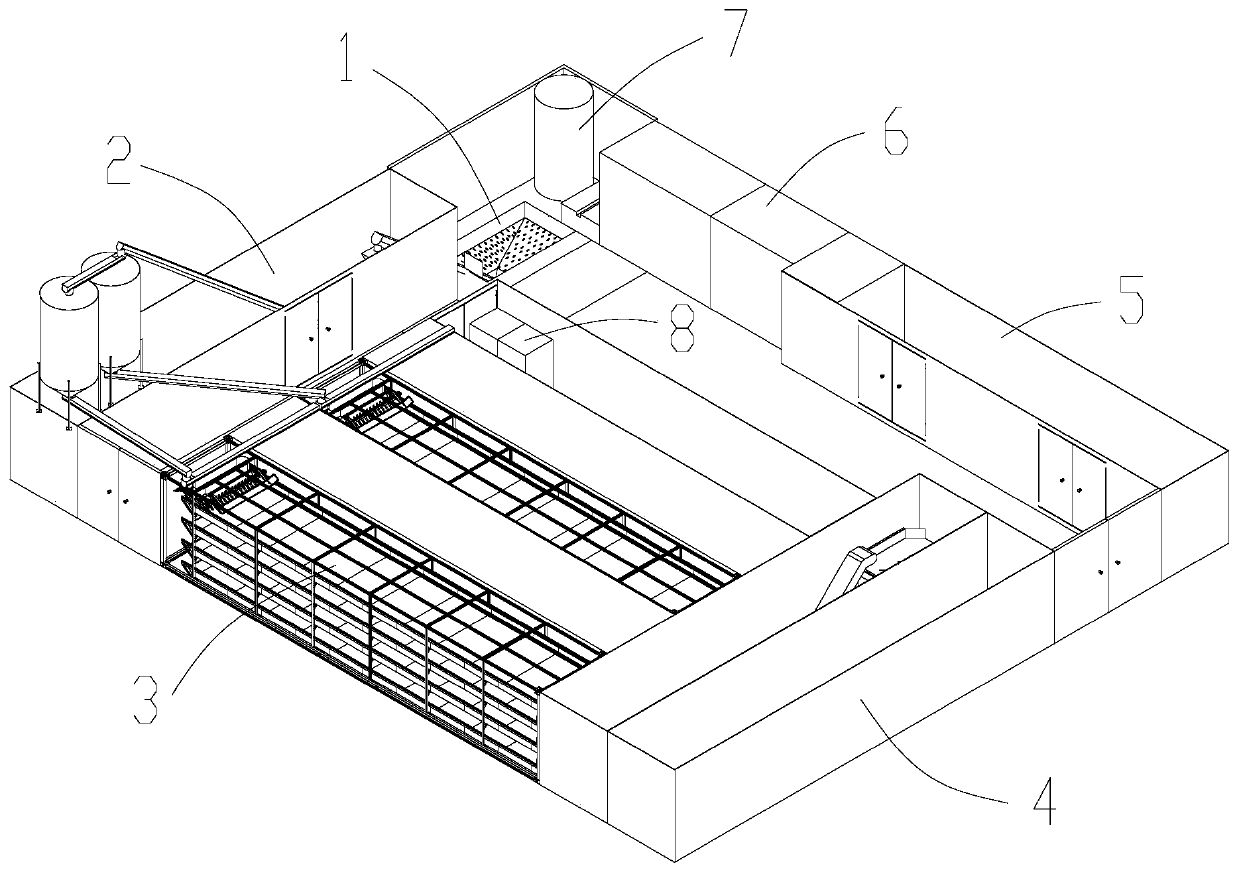

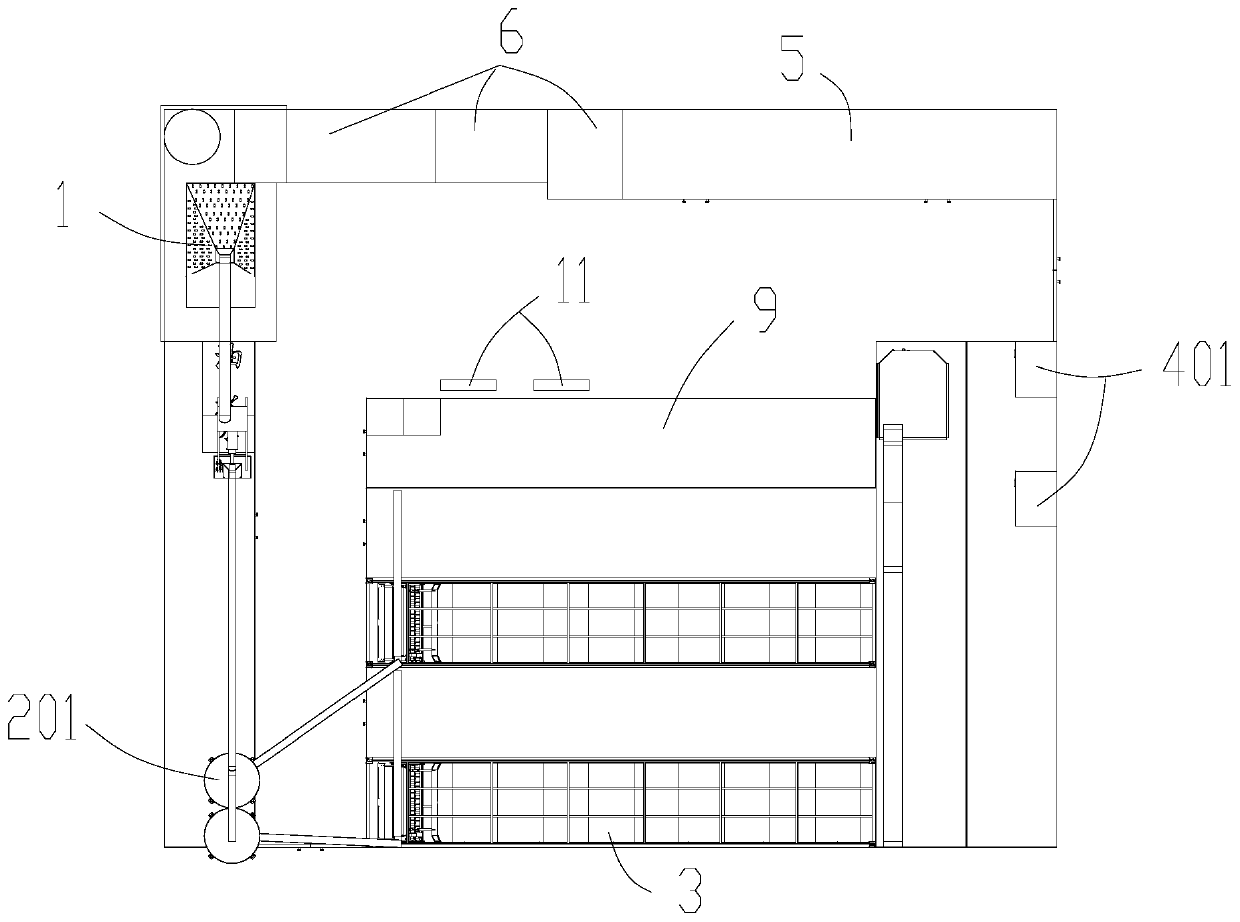

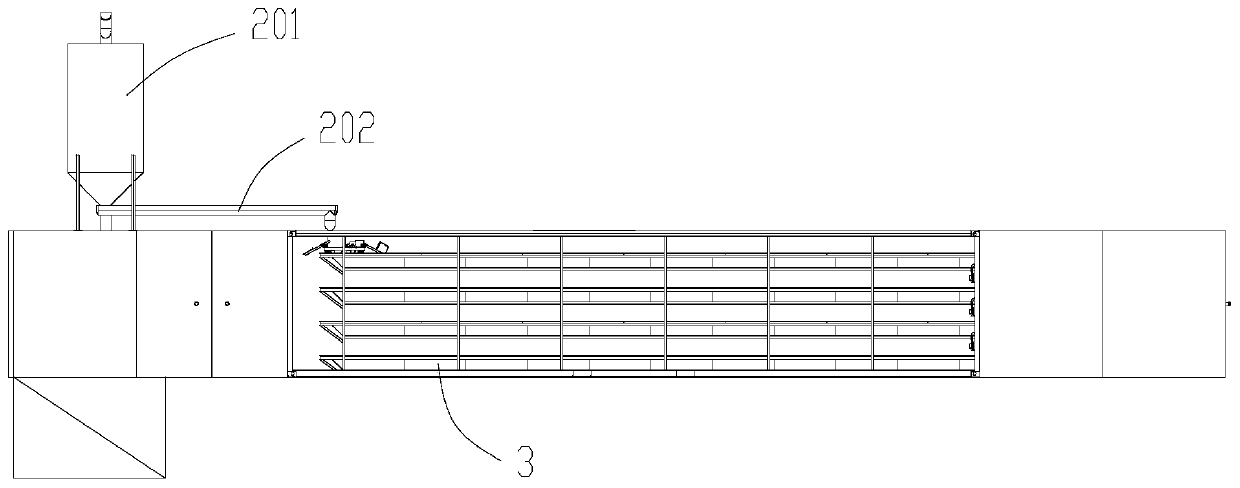

[0039] see Figure 1 to Figure 3 , the present embodiment is a food waste systematic treatment module, which has five single system components, namely pre-treatment system 1, fermentation system 2, hatching and breeding system 3, sorting system 4 and auxiliary system. Designed with a handling capacity of 20 tons per day, the floor area is about 24 meters x 20 meters (length * width). The system forms an enclosed factory to make full use of space and facilitate management. As the processing capacity increases, each component module can be supplemented at any time.

[0040] Each system will be described in detail below.

[0041] The pre-treatment system 1 is mainly for the preliminary sorting of food waste entering the factory. The processed objects include metal objects such as cans, large non-metall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com