Sludge-carbon organic fertilizer producing technology

A production process, sludge carbon technology, applied in fertilization equipment, fertilizer mixture, application, etc., can solve the problems that sludge fertilizer cannot be continuously operated normally, product backlog, occupying a large site, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

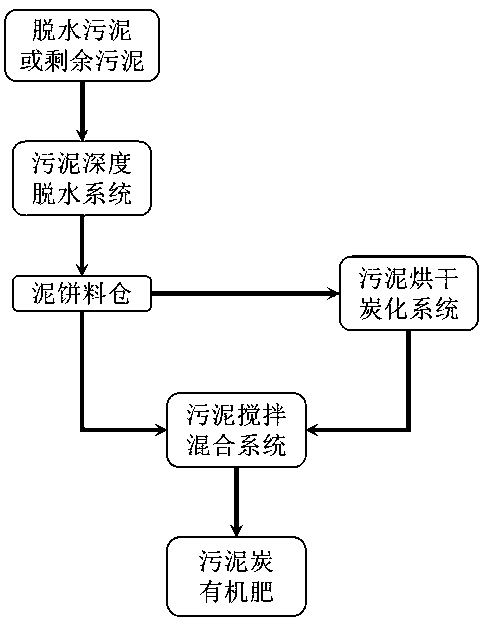

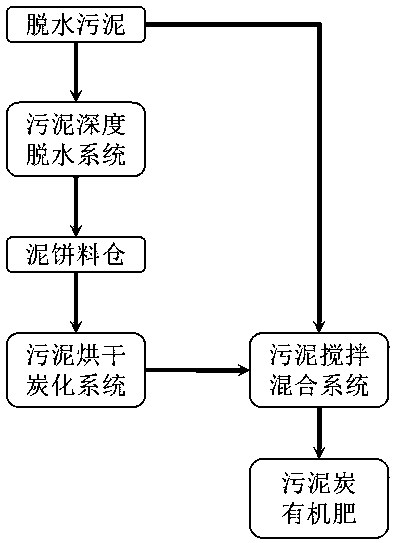

[0006] A kind of sludge charcoal organic fertilizer production process Specific implementation mode The remaining sludge enters the deep dehydration system for dehydration treatment to make dehydrated cake, the dehydrated cake is divided into two parts, one part enters the sludge drying and dewatering system to make sludge charcoal, and then Enter the sludge mixing system, and mix with another part of the dewatered cake evenly to make sludge charcoal organic fertilizer.

Embodiment approach 2

[0008] A kind of sludge charcoal organic fertilizer production process Specific implementation method Wet sludge enters the deep dehydration system for dehydration treatment to make dehydrated cake, the dehydrated cake is divided into two parts, one part enters the sludge drying and dewatering system to make sludge charcoal, and then enters The sludge mixing system is used to mix with another part of the dewatered cake evenly to make sludge charcoal organic fertilizer.

Embodiment approach 3

[0010] A kind of sludge charcoal organic fertilizer production process Specific implementation method The wet sludge is divided into two parts, one part enters the deep dehydration system for dehydration treatment to make dewatered cake, and then enters the sludge drying and dehydration system to make sludge charcoal, and then enters the sludge Stir the mixing system and mix with another part of wet sludge evenly to make sludge charcoal organic fertilizer.

[0011] The above implementation cases do not all represent the production of all equipment series, and will not give examples one by one here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com