High-performance conductive polymer hydrogel preparation method

A conductive polymer and hydrogel technology, applied in the production of bulk chemicals, etc., can solve the problems of high mechanical modulus and poor stability, and achieve the effects of convenient preparation, mild reaction conditions and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

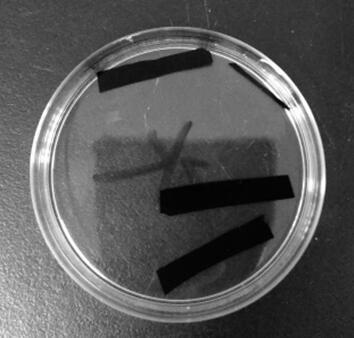

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing a high-performance conductive polymer hydrogel, and the specific implementation method is as follows.

[0025] Preparation of hydrogel:

[0026] 1. Prepare 5 parts of 25 mL PEDOT:PSS aqueous solution, add 5%, 10%, 15%, 25%, 50% dimethyl sulfoxide (DMSO) at a volume ratio and stir for 12 hours.

[0027] 2. Drop 5 parts of the solution on a 5 cm * 5 cm polyethylene terephthalate (PET) substrate, drop 10 mL per substrate, cover the entire substrate, and form the maximum surface tension at the edge of the substrate Contact angle and dry at 60°C for 24h. During the drying process, the substrate should be completely flat without any contact, and a large amount of CaCl should be placed 2 Desiccant, replace the desiccant every 4 hours, absorb the volatilized water, and dry until the PEDOT:PSS solution forms a film and the surface is completely dry.

[0028] 3. Self-supporting PEDOT:PSS films with different DMSO volume ratios were...

Embodiment 2

[0036] 1. Prepare 5 parts of 25 mL PEDOT:PSS aqueous solution, add 1-butyl-3-methylimidazolium tetrafluoroborate ((BMIm ) BF 4 ) and stirred for 12 h.

[0037] 2. Drop-coat 5 parts of the solution on a 5 cm*5 cm polypropylene substrate, drop 10 mL on each substrate, cover the entire substrate, form a maximum surface tension contact angle at the edge of the substrate and dry at 60 °C for 24 h . During the drying process, the substrate should be completely flat without any contact, and a large amount of CaCl should be placed 2 Desiccant, replace the desiccant every 4 hours, absorb the volatilized water, and dry until the PEDOT:PSS solution forms a film and the surface is completely dry.

[0038] 3. Obtaining different (BMIm) BFs by peeling dried samples from substrates 4 For a self-supporting PEDOT:PSS film with a volume ratio, the dried film was sandwiched between two flat and clean steel plates and further annealed at 130 °C for 30 min. Annealing at elevated temperatures a...

Embodiment 3

[0046] 1. Prepare 25 mL of PEDOT:5 parts of PSS aqueous solution, add 5%, 10%, 15%, 25%, 50% sodium dodecylsulfonate (SDS) by weight and stir for 12 h.

[0047] 2. Drop 5 parts of the solution on a 5 cm*5 cm polyethylene terephthalate (PET) substrate, drop 10 mL per substrate, cover the entire substrate, and form the maximum surface tension at the edge of the substrate contact angle and dried at 60°C for 24 h. During the drying process, the substrate should be completely flat without any contact, and a large amount of CaCl should be placed 2 Desiccant, replace the desiccant every 4 hours, absorb the volatilized water, and dry until the PEDOT:PSS solution forms a film and the surface is completely dry.

[0048] 3. Self-supporting PEDOT:PSS films with different weight ratios of SDS were obtained by peeling the dried samples from the substrate. The dried films were sandwiched between two flat and clean steel plates, and further annealed at 130 °C for 30 min. Annealing at a temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com