Shearing responding gel plugging agent and preparation method and applications thereof

A technology of plugging agent and gel, which is applied in the field of shear-responsive gel plugging agent and its preparation, can solve the problems of fluid dilution, gravity sedimentation, and low gel strength of gel, and achieve weak gravity sedimentation , strong toughness, good anti-dilution effect of formation fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0102] The second aspect of the present invention provides a method for preparing the above-mentioned shear-responsive gel plugging agent, comprising the following steps:

[0103] (1) adding the polymer complex monomer and the solid-phase organic macromolecular cross-linking agent into clear water, and stirring at the first stirring speed until completely dissolved to obtain the mixed solution a;

[0104] (II) adding the rheology modifier into the mixed solution a, stirring at the second stirring speed until uniformly dispersed, and obtaining the mixed solution b;

[0105] (III) Add the toughening agent into the mixed solution b, stir at the third stirring speed until uniformly dispersed, and obtain the mixed solution c;

[0106] (IV) Add the first initiator to the mixed solution c, stir at the fourth stirring speed until completely dissolved, and obtain the mixed solution d;

[0107] (V) sealing the mixed liquid d and standing still, and curing to form a gel, so as to obtain...

preparation example 1

[0123] (1) 5 g of acrylamide / methacrylic acid (mass ratio 3:1) mixed monomer and 0.1 g of ammonium persulfate were dissolved in 6 ml and 4 ml of deionized water, respectively, to obtain monomer solution A1 and initiator solution A2;

[0124] (2) Mix 9g of Span60 / Span80 (mass ratio 1:2) and 15g of Tween60 / Tween80 (mass ratio 2:1) and mix them with 60ml cyclohexane to obtain solution B

[0125] (3) Slowly add solution A1 dropwise to solution B, and stir to obtain solution C;

[0126] (4) Slowly add the solution A2 dropwise to the solution C and stir evenly, and after standing at 60° C. for 4 hours to react, the microemulsion D is obtained;

[0127] (5) Add 1.2 g of N-methylolacrylamide to microemulsion D, and adjust the pH to weakly acidic 4-5 to obtain microemulsion F;

[0128] (6) The microemulsion F was mixed with absolute ethanol to precipitate solid-phase substances, then repeatedly washed with acetone and dried for 5 hours to obtain a solid-phase organic macromolecular cr...

preparation example 2

[0130] (1) adding the polymer composite monomer and the solid-phase organic macromolecular cross-linking agent into clear water, and stirring at 700 rpm until it completely dissolves to obtain the mixed solution a;

[0131] (II) adding a rheology modifier into the mixed solution a, and stirring at 400 rpm until it is uniformly dispersed to obtain a mixed solution b;

[0132] (III) Add the toughening agent into the mixed solution b, and stir at 100 rpm until it is uniformly dispersed to obtain the mixed solution c;

[0133] (IV) Add the first initiator to the mixed solution c, stir until it is completely dissolved at 100 rpm to obtain the mixed solution d; seal the mixed solution d and place it at 80° C., and solidify into a gel to obtain Shear-responsive gel plugging agent, wherein the first initiator is an oxidation-reduction system composed of ammonium persulfate and sodium bisulfite, and the mass ratio of oxidizing agent to reducing agent is 0.9:1. .

PUM

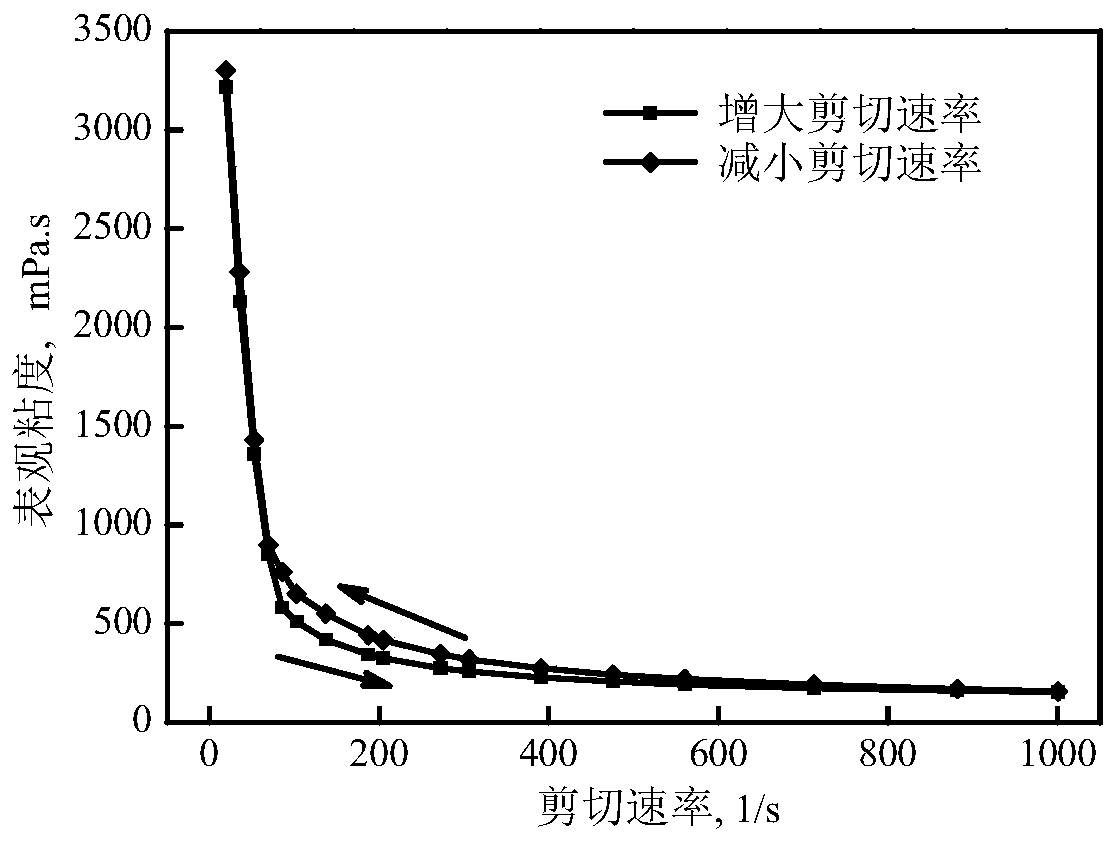

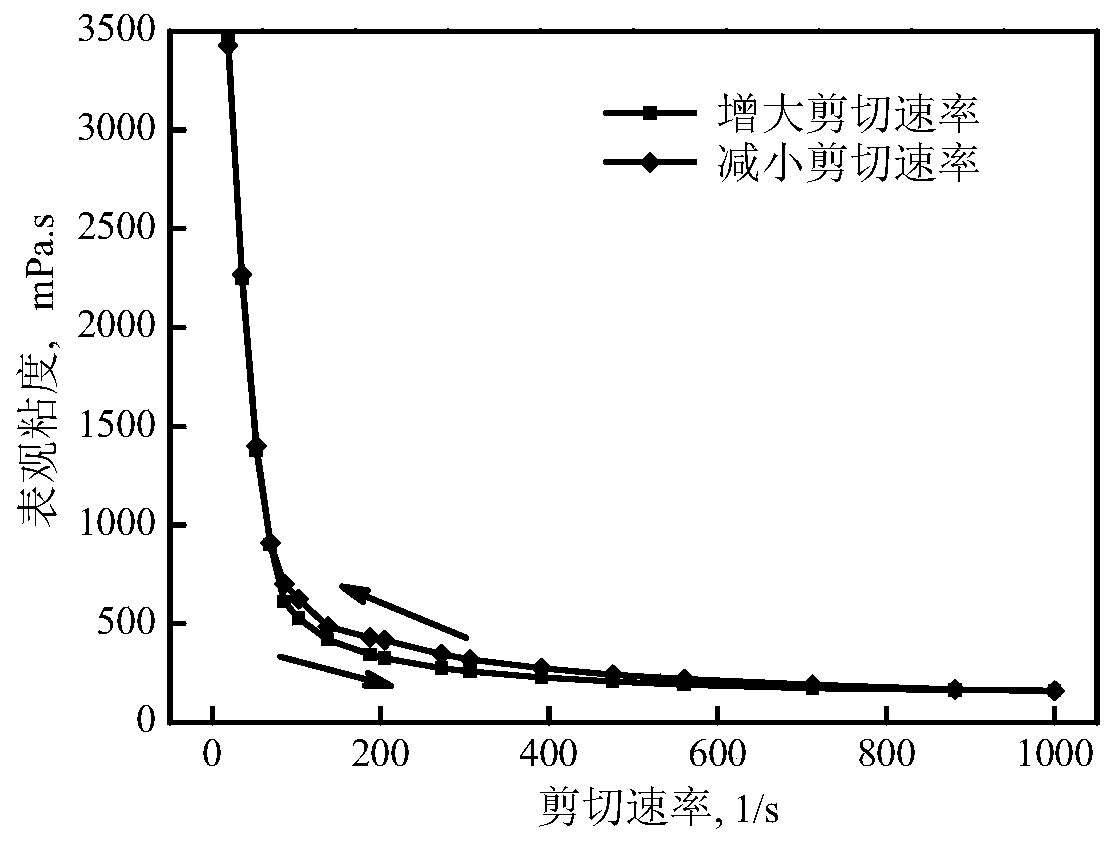

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com