A method for fabricating surface-enhanced Raman substrates based on localized optical field-enhanced femtosecond laser photoreduction

A surface-enhanced Raman and femtosecond laser technology, applied in Raman scattering, material excitation analysis, nanotechnology, etc., can solve problems such as dispersion of gold nanostructures, and achieve enhanced enhancement factor, reduced size, and good chemical stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for fabricating a surface-enhanced Raman substrate based on femtosecond laser photoreduction based on localized light field enhancement, the steps of which are as follows:

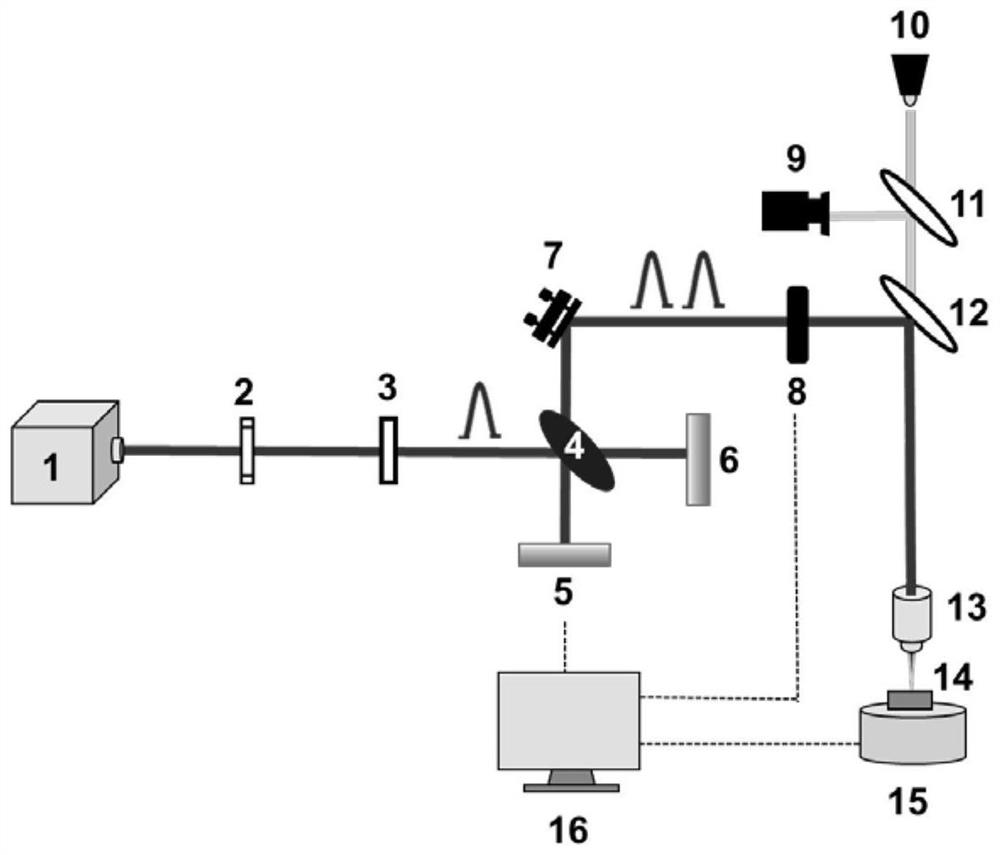

[0036] (1) build as figure 1 The femtosecond laser processing system shown;

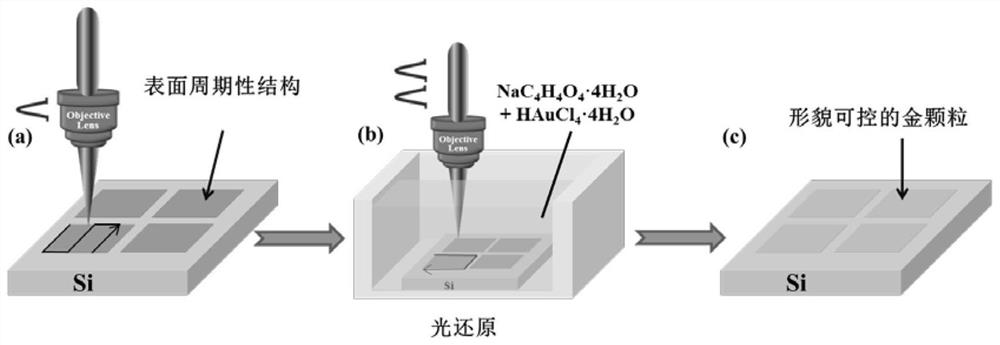

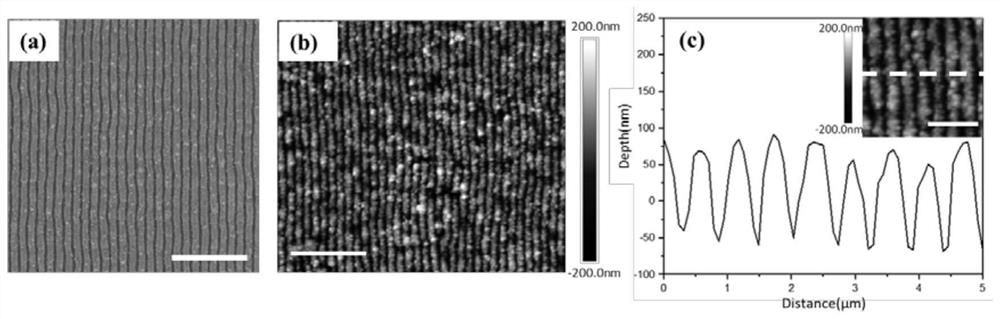

[0037] (2) if figure 2 As shown in (a), in air, a single-pulse femtosecond laser is used to fabricate a flat silicon substrate such as image 3 The large-area surface periodic structure shown;

[0038] (3) if figure 2 As shown in (b), the silicon substrate with the surface periodic structure processed once is placed in a cuvette, and HAuCl is added to the cuvette 4 and KNaC 4 h 4 o 6 The mixed solution until the substrate is submerged, and then a second scan is performed in the surface periodic structure area at the solid-liquid interface to achieve photoreduction;

[0039] (4) After a two-step experimental process, a large number of gold nanoparticles are attached to the surface periodic structure. By ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com