Preparation method of modulation grating for x-ray all-optical solid-state ultrafast detection chip and grating

A technique for modulating gratings and X-rays, used in measurement devices, material analysis using wave/particle radiation, instruments, etc. problems, to achieve effective blocking, structural integrity, good transmittance and reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

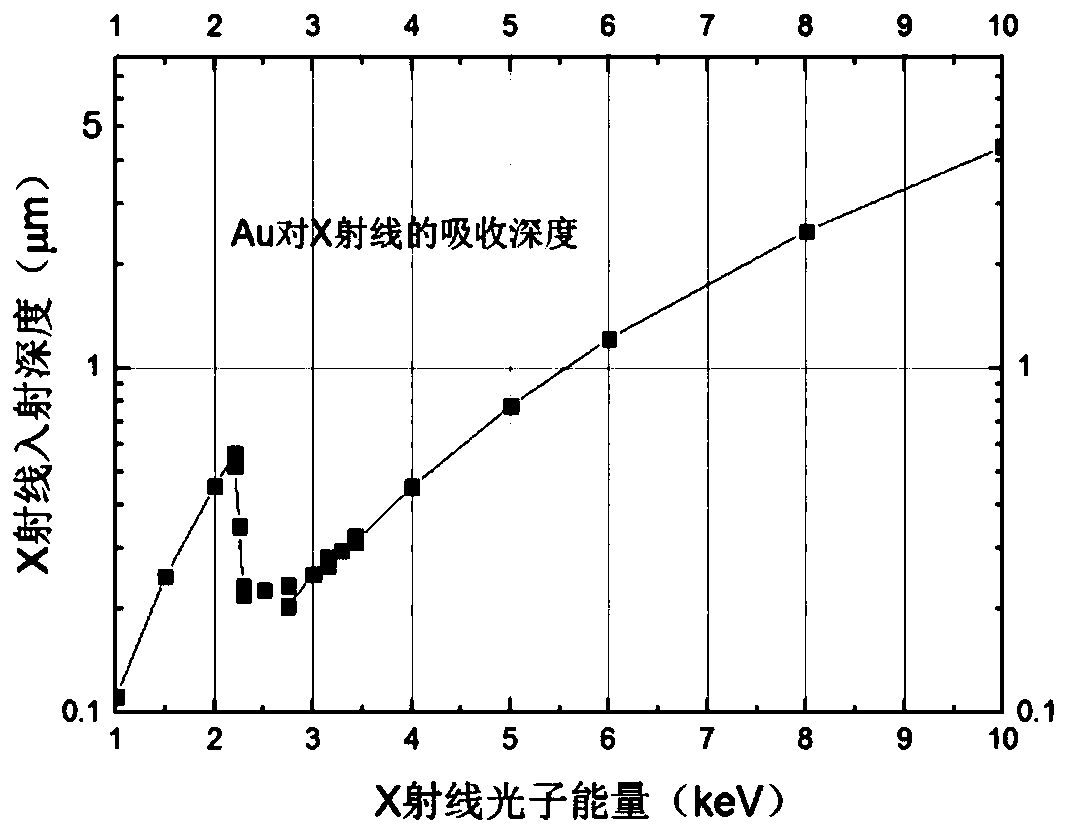

[0044] For chip testing, X-rays with an incident signal light of 4.5KeV and a wavelength of probe light of 800nm are used. In order to effectively modulate X-rays and block incident high-energy X-rays, the chip selects Au with a high atomic number as the material of the X-ray modulation grating.

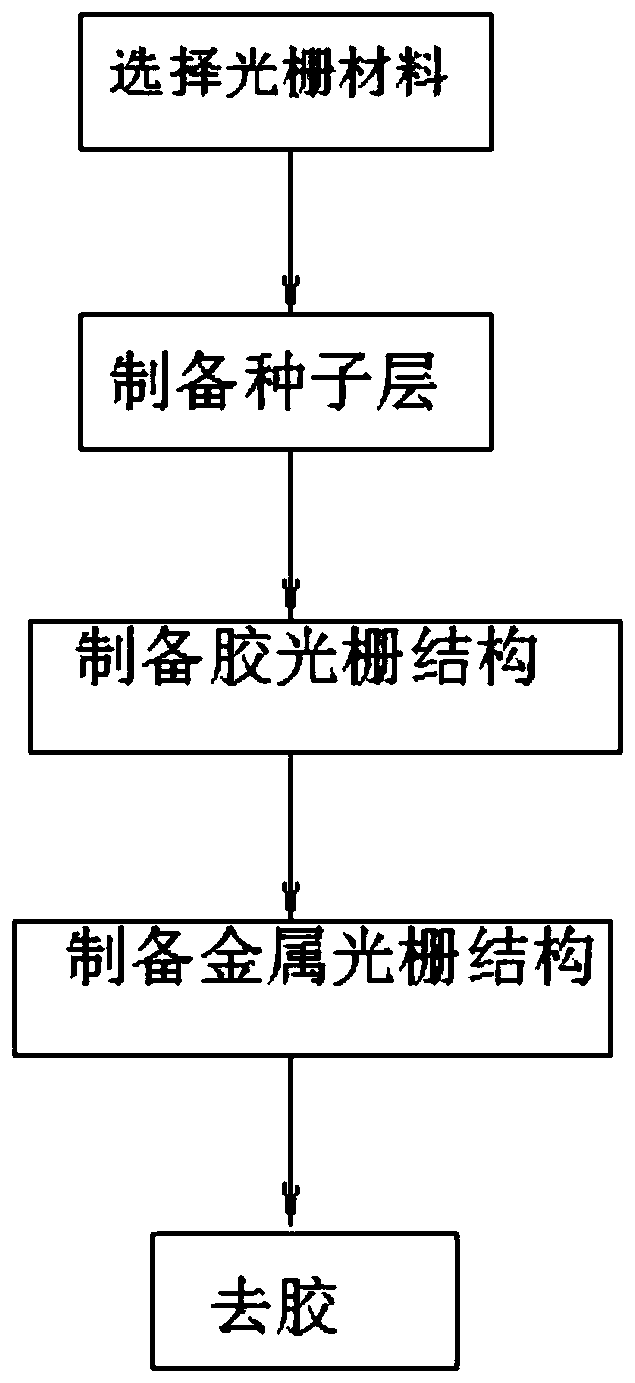

[0045] Such as figure 1 As shown, the preparation method of the X-ray all-optical solid-state ultrafast detection chip modulation grating proposed by the present invention comprises the following steps:

[0046] Step 1, using the epitaxial surface of the all-optical solid ultrafast detection chip epitaxial wafer as the substrate of the grating material, selecting a suitable grating material, and the grating material is a metal material that can effectively absorb X-rays;

[0047] Because X-rays have extremely strong penetr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com