High-hardness high-dielectric constant cover plate with AR and AF functions

A technology with high dielectric constant and dielectric constant is applied in the field of flat panel display devices, which can solve the problems of expensive cost and complicated sapphire processing technology, and achieve the effect of improving sensitivity and anti-interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

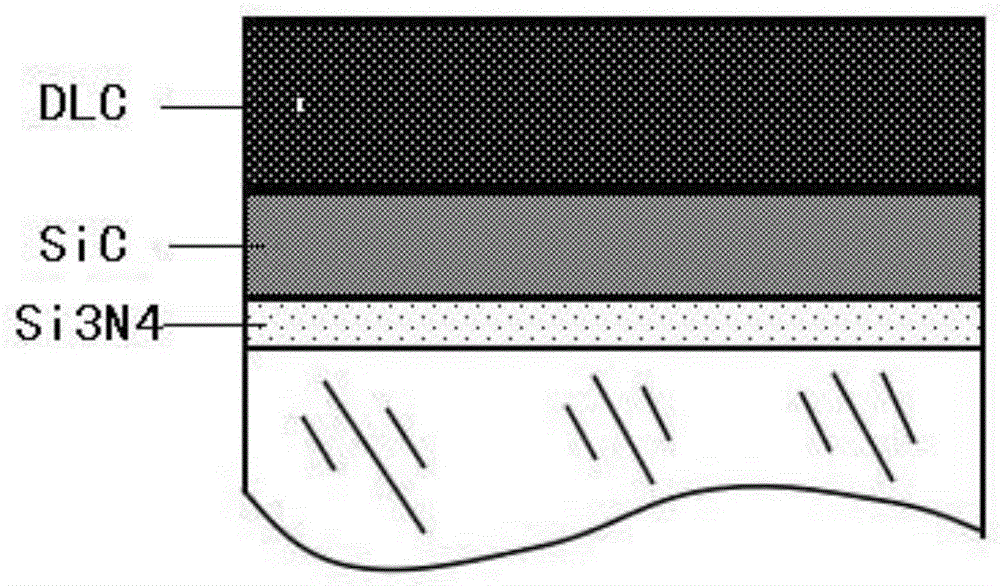

[0022] see figure 1 , the structure of the cover plate of this embodiment is Si3N4 / SiC / DLC, the thickness of Si3N4 is between 40-50nm, the thickness of SiC is between 45-55nm, and the thickness of DLC is between 30-40nm, using continuous online magnetron Sputtering method, SiC and DLC layers use silicon target and graphite target respectively, the preparation temperature is normal temperature, Ar and N2 and CF4 gas are introduced to the working vacuum of 0.25Pa, the power density of the target is 2-3W / cm2, and the deposition rate is low The method is to coat tempered glass or other optical plastic substrates. The cover plate of this embodiment has AR and AF functions, the hardness is 32GPa, and the dielectric constant is 11.

Embodiment 2

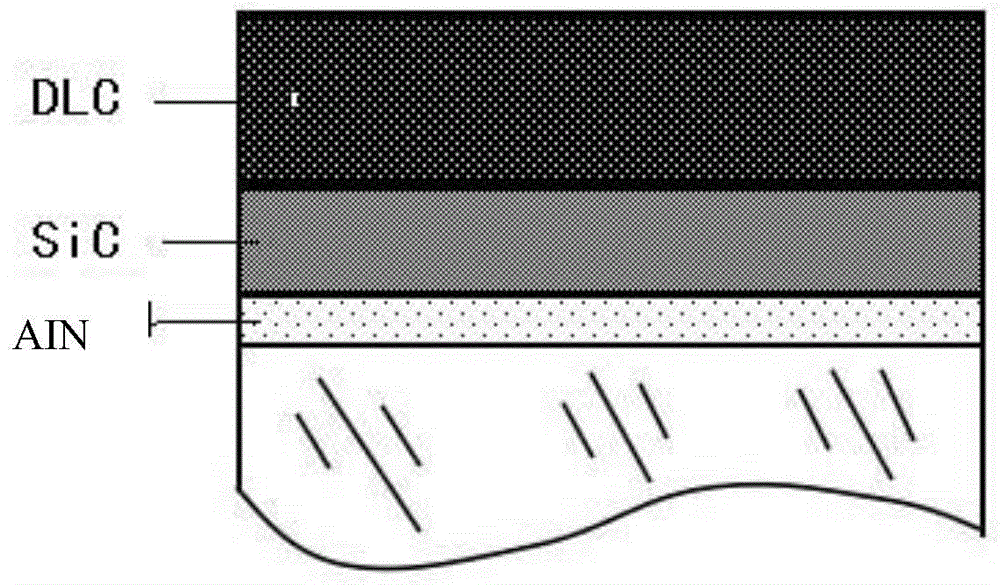

[0024] see figure 2 , the cover plate structure of this embodiment is AlN / SiC / DLC, the thickness of AlN is between 30-50nm, the thickness of SiC is between 45-55nm, and the thickness of DLC is between 40-100nm. Continuous online magnetron and The method of multi-arc ion plating, AlN adopts aluminum target, SiC adopts silicon target, DLC adopts graphite target, the preparation temperature is normal temperature, feed Ar and N2 and use magnetron sputtering to prepare AlN, feed Ar and CH4 and use magnetron sputtering to prepare SiC, and Ar and CF4 use multi-arc ion plating method, working vacuum at 0.25Pa, target current at 20-40A, adopt low deposition rate method to coat toughened glass or other optical plastic substrates, adopt low deposition rate method Deposit the DLC film. The cover plate of this embodiment has AR and AF functions, the hardness is 35GPa, and the dielectric constant is 10.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com