Mirau Super-resolution Interference Microscope Objectives

An interference microscopy and super-resolution technology, applied in microscopes, instruments, optics, etc., can solve the problems of non-optical imaging operation mode, poor experiment repeatability, and short observation time, and achieve compact structure, small measurement error, and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

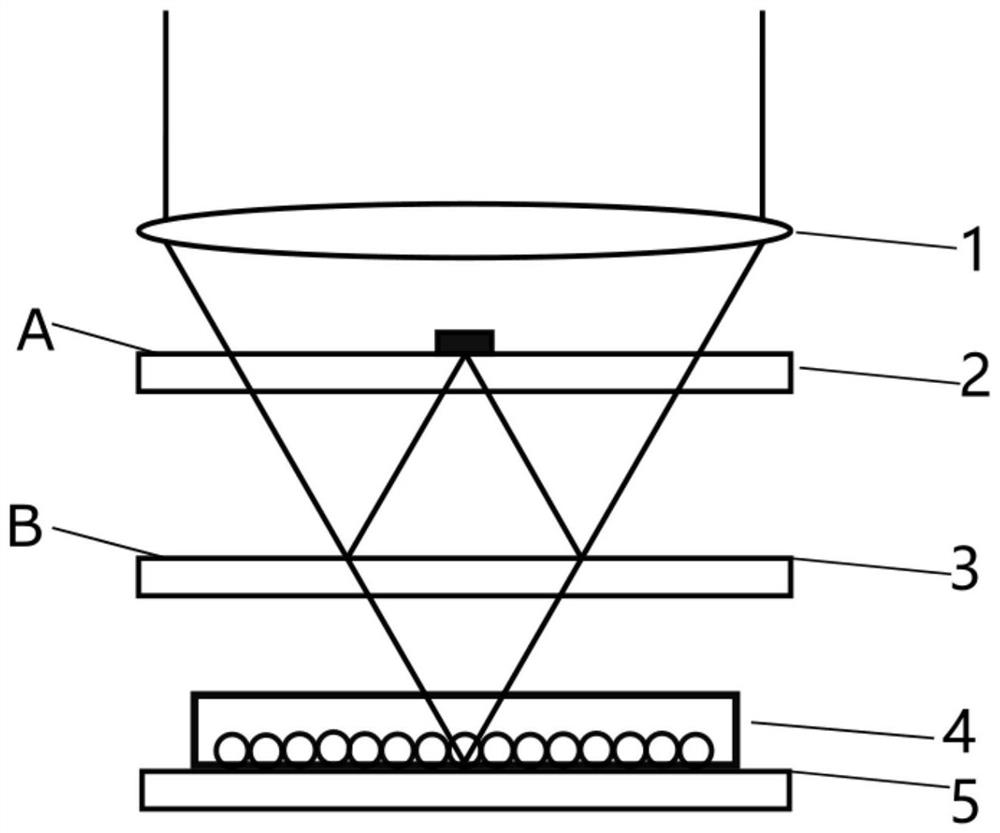

Method used

Image

Examples

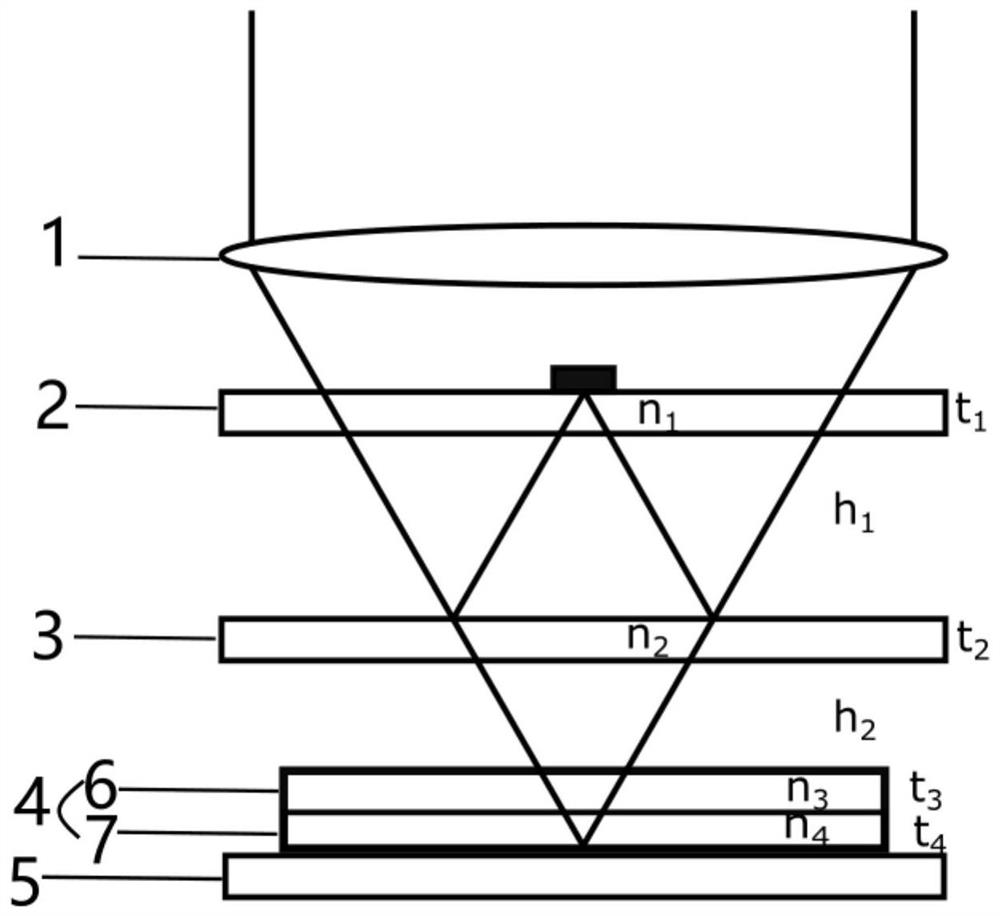

Embodiment 1

[0038] In this example, we used a barium titanate microsphere array with a diameter of 50 μm combined with a PDMS film to make the microsphere lens film 4. The specific preparation method has been disclosed in the patent 201610113464.2. The total thickness of the microsphere lens film 4 is 100 μm. The thickness information of the reference plate 2 and the spectroscopic plate 3 is determined according to the formula of equal optical path length under the central wavelength. Spectroscopic plate 3 material fused silica (refractive index 1.4606, Abbe number 67.82), thickness 1mm, reference plate 2 material fused silica (refractive index 1.4606, Abbe number 67.82), thickness 1.132 mm, distance between reference plate 2 and spectroscopic plate 3 is 3 mm, and the distance from the reference plate to the microsphere lens film is 3 mm.

[0039] In this example, the microsphere lens film 4 is equivalent to the superposition of the microsphere plate 6 and the film plate 7, the material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com