Graphene/niobium pentoxide composite electrode material and manufacturing method thereof

A technology of niobium pentoxide and composite electrodes, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of affecting the three-dimensional structure of graphene, the crystal structure of transition metal oxides, the electrical properties of electrode materials, etc., so as to shorten the transmission time. Path, preparation reproducibility, mild conditions effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

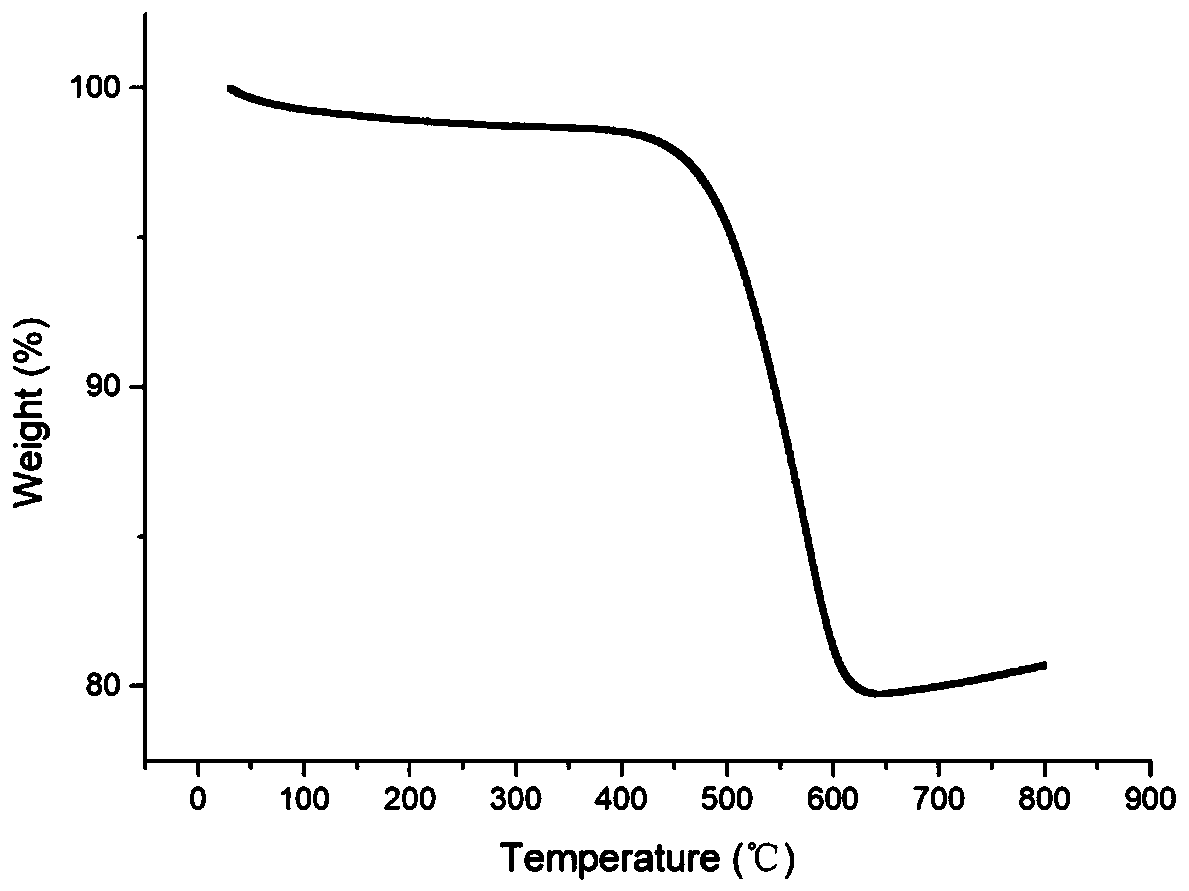

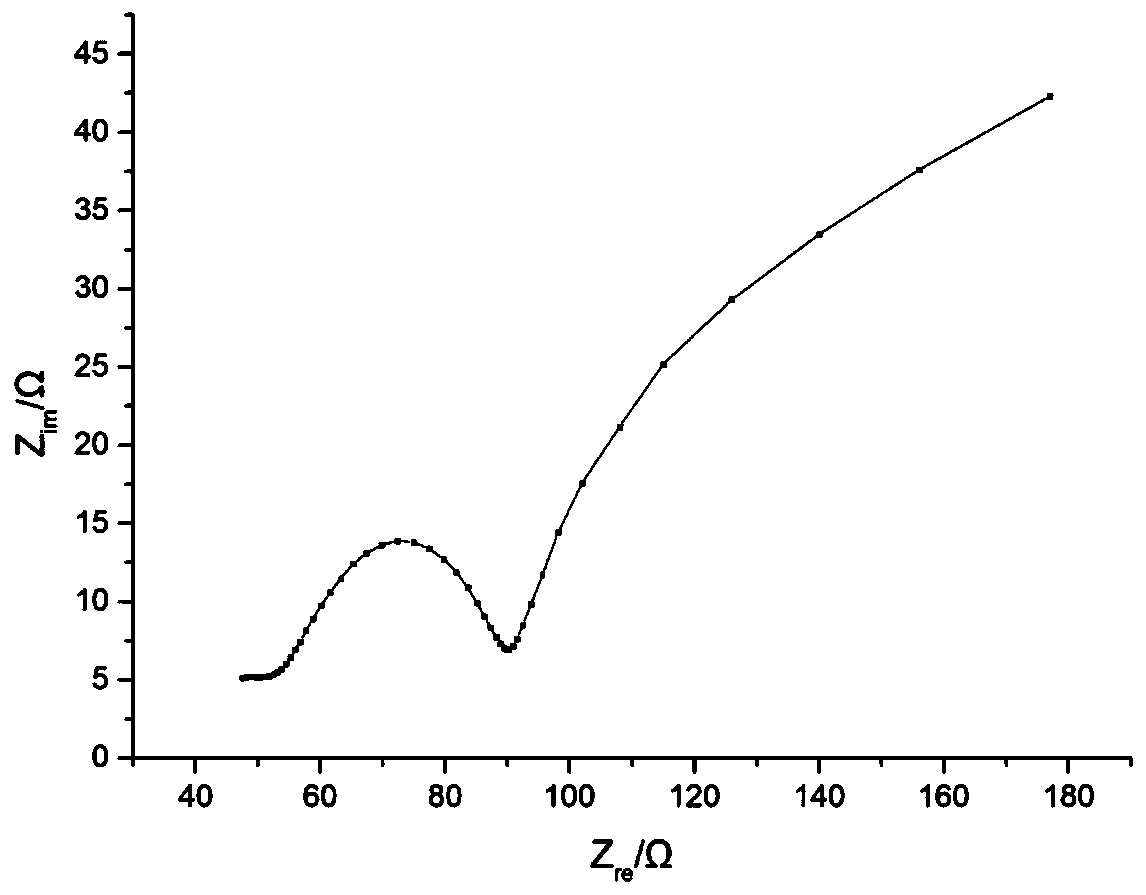

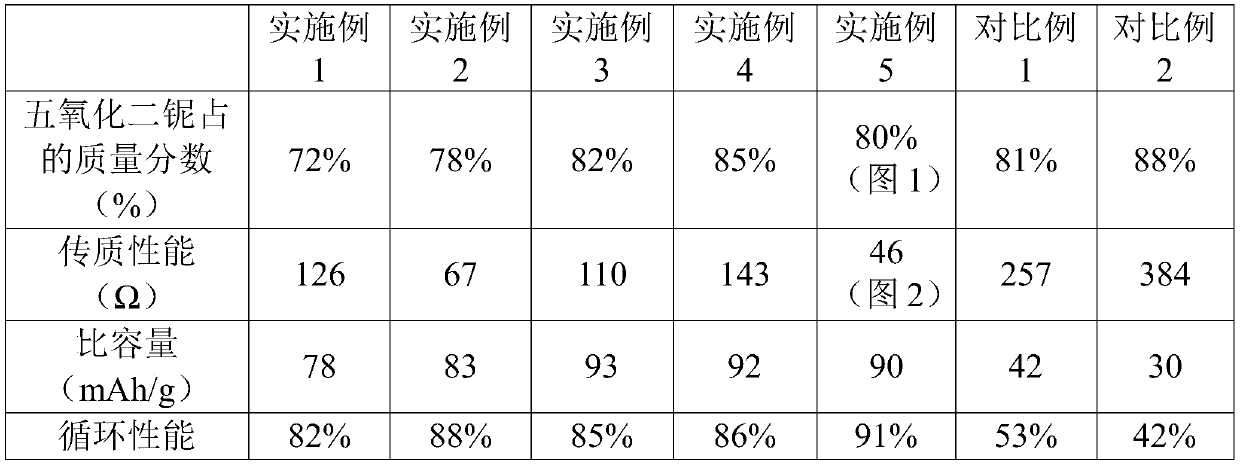

Examples

Embodiment 1

[0035] In this embodiment, a method for preparing a graphene / niobium pentoxide three-dimensional composite electrode material, the steps are as follows:

[0036] (1) Add 0.3g of N,N'-dicyclohexylcarbodiimide to 40mL of graphene oxide dispersion with a concentration of 5.0mg / mL, heat to 90°C under sufficient stirring, and reflux for 3h.

[0037] (2) Dissolve 0.7g of niobium pentachloride in 10mL of absolute ethanol, then add it to the mixture in step (1), heat to 90°C under sufficient stirring, and reflux for 1h.

[0038] (3) Add 0.5 g of sodium ascorbate to the mixture in step (2), heat to 90° C. under sufficient stirring, and reflux for 1 h.

[0039] (4) The mixed solution prepared in step (3) was transferred to a 100 mL solvothermal reaction kettle and reacted at 190° C. for 15 h. The solvothermal product was separated by suction filtration to obtain a solid, which was washed three times with deionized water and absolute ethanol, respectively, and dried under vacuum at 50°C...

Embodiment 2

[0042] In this embodiment, a method for preparing a graphene / niobium pentoxide three-dimensional composite electrode material, the steps are as follows:

[0043] (1) Add 0.4g of N,N'-dicyclohexylcarbodiimide to 50mL of graphene oxide dispersion with a concentration of 4.0mg / mL, heat to 90°C under sufficient stirring, and reflux for 3h.

[0044] (2) Dissolve 0.8g of niobium pentachloride in 10mL of absolute ethanol, then add it to the mixture in step (1), heat to 90°C under sufficient stirring, and reflux for 1h.

[0045] (3) Add 0.5 g of sodium ascorbate to the mixture in step (2), heat to 90° C. under sufficient stirring, and reflux for 1 h.

[0046] (4) The mixed solution prepared in step (3) was transferred to a 100 mL solvothermal reaction kettle and reacted at 190° C. for 15 h. The solvothermal product was separated by suction filtration to obtain a solid, which was washed three times with deionized water and absolute ethanol, respectively, and dried under vacuum at 50°C...

Embodiment 3

[0049] In this embodiment, a method for preparing a graphene / niobium pentoxide three-dimensional composite electrode material, the steps are as follows:

[0050] (1) Add 0.4g of N,N'-dicyclohexylcarbodiimide to 50mL of graphene oxide dispersion with a concentration of 4.0mg / mL, heat to 90°C under sufficient stirring, and reflux for 3h.

[0051] (2) Dissolve 1.0 g of niobium pentachloride in 15 mL of absolute ethanol, then add it to the mixture in step (1), heat to 90° C. under sufficient stirring, and reflux for 1 h.

[0052] (3) Add 0.5 g of sodium ascorbate to the mixture in step (2), heat to 100° C. under sufficient stirring, and reflux for 1 h.

[0053] (4) The mixed solution prepared in step (3) was transferred to a 100 mL solvothermal reaction kettle and reacted at 190° C. for 15 h. The solvothermal product was separated by suction filtration to obtain a solid, which was washed three times with deionized water and absolute ethanol, respectively, and dried under vacuum at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com