Flexible polyurethane foam plastic and processing method thereof

A soft polyurethane and foamed plastic technology, applied in the field of polyurethane products, can solve the problems of large foam volume, poor resilience performance, poor use comfort, etc., and achieve the effect of scientific and reasonable ratio and good resilience performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

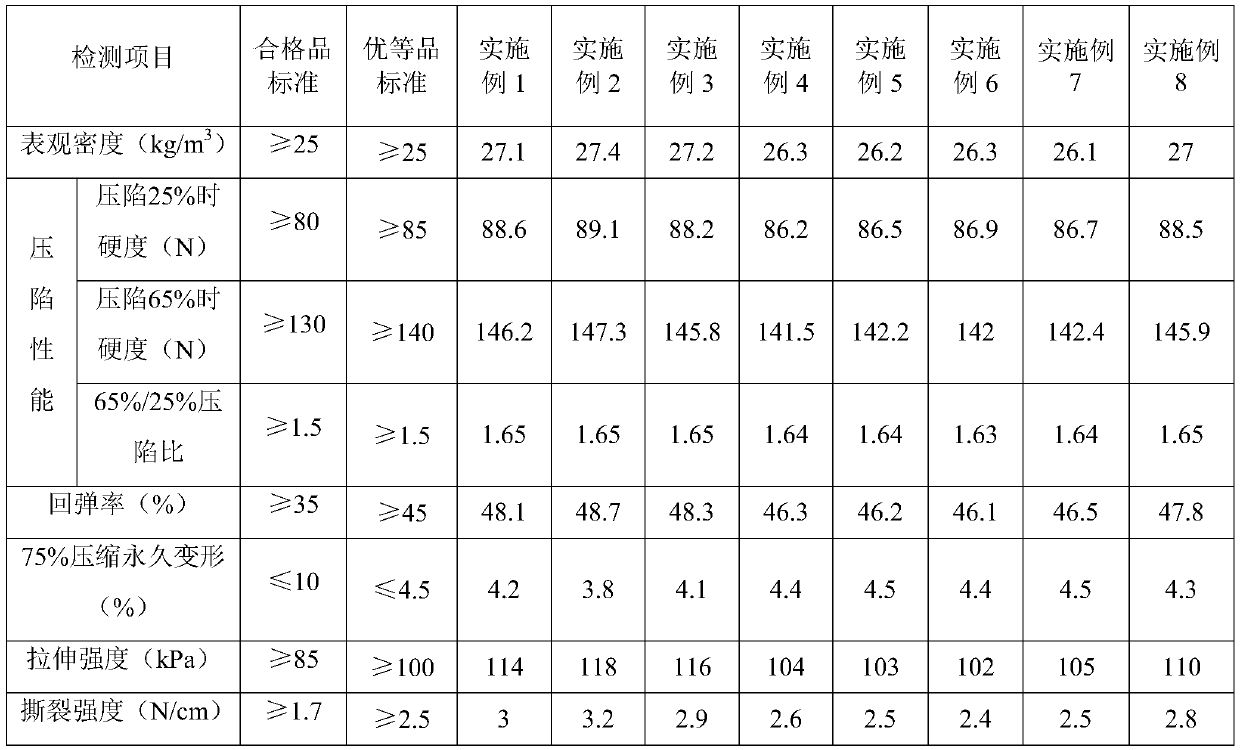

Examples

Embodiment 1

[0028] A flexible polyurethane foam:

[0029] In parts by weight, the following components are included: 100 parts of polyether polyol, 30 parts of toluene diisocyanate, 1 part of water, 0.1 part of triethylenediamine, 0.1 part of stannous octoate, 0.3 part of silicone oil, and 23 parts of fiber reinforced composition parts, wherein, by weight, the fiber reinforced composition comprises 2 parts of carbon fiber, 5 parts of spandex fiber, 14 parts of bamboo fiber, and 2 parts of coupling agent; coupling agent is selected silane coupling agent, and antioxidant is selected ultraviolet absorber UV -531, the specifications of the three fibers are all 100D, and the length is 4mm; the preparation steps include:

[0030] S1, in parts by weight, mixing the raw material components of the fiber reinforced composition for 20 minutes at 500 r / min to obtain a fiber reinforced composition;

[0031] S2, in parts by weight, the fiber reinforced composition is mixed with the remaining component...

Embodiment 2

[0033] A flexible polyurethane foam:

[0034] In parts by weight, the preparation raw materials include the following components: 100 parts of polyether polyol, 40 parts of toluene diisocyanate, 3 parts of water, 0.3 part of triethylenediamine, 0.3 part of stannous octoate, 0.7 part of silicone oil, fiber reinforced combination 25 parts, wherein, by weight, the fiber reinforced composition comprises 3 parts of carbon fiber, 6 parts of spandex fiber, 16 parts of bamboo fiber, 2.5 parts of coupling agent, and 2.3 parts of antioxidant; the coupling agent is selected from silane coupling agent, Antioxidant uses ultraviolet absorber UV-531, the specifications of the three fibers are all 120D, and the length is 5mm;

[0035] Preparation steps include:

[0036] S1, in parts by weight, mixing the raw material components of the fiber-reinforced composition for 25 minutes at 550 r / min to obtain a fiber-reinforced composition;

[0037] S2, in parts by weight, the fiber-reinforced compo...

Embodiment 3

[0039] A flexible polyurethane foam:

[0040] In parts by weight, the raw materials for preparation include the following components: 100 parts of polyether polyol, 50 parts of toluene diisocyanate, 5 parts of water, 0.5 part of triethylenediamine, 0.5 part of stannous octoate, 1.5 parts of silicone oil, fiber reinforced combination 27 parts, wherein, by weight, the fiber reinforced composition comprises 5 parts of carbon fiber, 8 parts of spandex fiber, 17 parts of bamboo fiber, 3.4 parts of coupling agent, and 3.4 parts of antioxidant; the coupling agent is selected from silane coupling agent, Antioxidant uses ultraviolet absorber UV-531, the specifications of the three fibers are all 150D, and the length is 6mm;

[0041] Preparation steps include:

[0042] S1, in parts by weight, mixing the raw material components of the fiber-reinforced composition for 30 minutes at 600 r / min to obtain a fiber-reinforced composition;

[0043] S2, in parts by weight, the fiber-reinforced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap