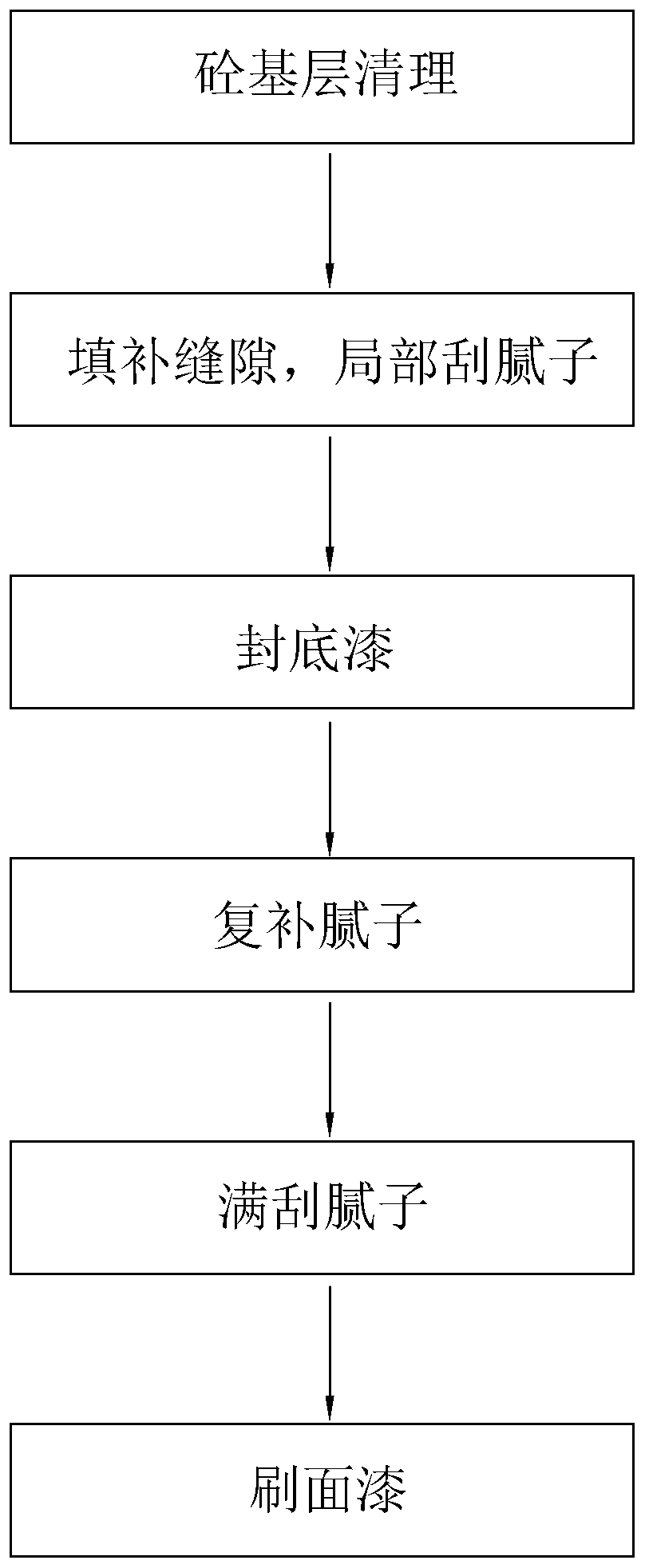

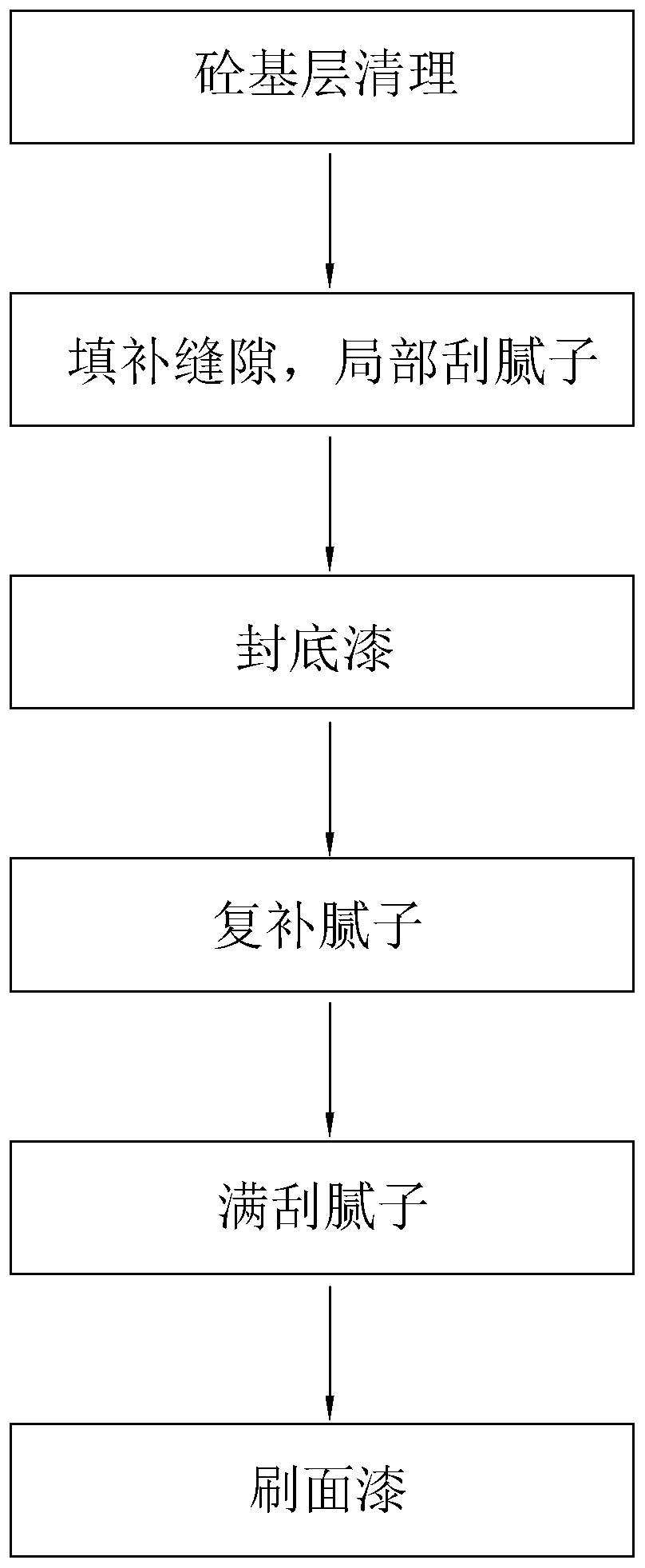

Construction process of inner wall latex paint

A technology for interior wall latex paint and construction technology, which is applied in the construction technology field of interior wall latex paint, can solve the problems of latex paint with poor adhesion, hollow glass microspheres, and poor adhesion, and achieve good adhesion, Excellent thermal insulation and noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A construction technique for interior wall latex paint, comprising the following steps:

[0034] S1, concrete base cleaning: remove floating sand, dust and pimples on the surface of the concrete base, use caustic soda and water in a ratio of 1:9 by weight to clean the surface of the concrete base, and then rinse the alkaline water with clean water until The PH of the concrete base is less than 10, and the concrete base is dried to a moisture content of 5%;

[0035] S2. Fill the gaps and scrape the putty locally: Use putty to level the local gaps and potholes. After the partial putty is dry, sand it with sandpaper and remove the floating dust;

[0036] S3, full scraping putty: the full scraping putty is operated twice, and the thickness of each full scraping putty is not more than 0.5mm. After each full scraping putty is dry, smooth it with sandpaper and remove the floating dust;

[0037] S4, primer;

[0038] S5. Repair the putty: After the primer is dry, repair the pu...

Embodiment 2

[0042] A construction technique for interior wall latex paint, comprising the following steps:

[0043] S1, concrete base cleaning: remove floating sand, dust and pimples on the surface of the concrete base, use alkaline water prepared by caustic soda and water in a weight ratio of 1:10 to clean the surface of the concrete base, and then rinse the alkaline water with clean water to The PH of the concrete base is less than 10, and the concrete base is dried to a moisture content of 8%;

[0044] S2. Fill the gaps and scrape the putty locally: Use putty to level the local gaps and potholes. After the partial putty is dry, sand it with sandpaper and remove the floating dust;

[0045] S3, full scraping putty: the full scraping putty is operated twice, and the thickness of each full scraping putty is not more than 0.5mm. After each full scraping putty is dry, smooth it with sandpaper and remove the floating dust;

[0046] S4, primer;

[0047] S5. Repair the putty: After the primer...

Embodiment 3

[0051] A construction technique for interior wall latex paint, comprising the following steps:

[0052] S1, concrete base cleaning: remove floating sand, dust, and lumps on the surface of the concrete base, use alkaline water prepared by caustic soda and water in a weight ratio of 1:12 to clean the surface of the concrete base, and then rinse the alkaline water with clean water to The PH of the concrete base is less than 10, and the concrete base is dried to a moisture content of 10%;

[0053] S2. Fill the gaps and scrape the putty locally: Use putty to level the local gaps and potholes. After the partial putty is dry, sand it with sandpaper and remove the floating dust;

[0054] S3, full scraping putty: the full scraping putty is operated twice, and the thickness of each full scraping putty is not more than 0.5mm. After each full scraping putty is dry, smooth it with sandpaper and remove the floating dust;

[0055] S4, primer;

[0056] S5. Repair the putty: After the primer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com