Fireproof composite board base material and preparation method thereof, and fireproof composite board

A composite board and substrate technology, applied in applications, furniture parts, household appliances, etc., can solve the problems of increasing manufacturing costs, strengthening, and increasing the complexity of fire-resistant composite boards, and achieves reduced processing difficulty, low cost, and excellent fire resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

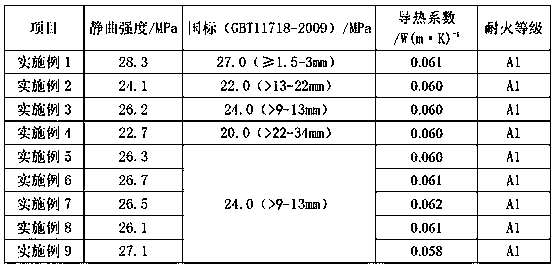

Examples

Embodiment 1

[0055] A kind of fireproof composite board base material, its raw material composition is,

[0056] Bamboo Powder 300kg

[0057] Magnesium sulfate 200kg

[0059] Perlite 20kg

[0060] Citric acid 50kg

[0061] 200kg of water.

[0062] The preparation method comprises the following steps,

[0063] Weighing: Weigh bamboo powder, magnesium sulfate, magnesium oxide, perlite, citric acid and water according to the above ratio;

[0064] Mixing material: add the weighed bamboo powder, magnesium oxide, and perlite into the powder mixer and mix evenly to obtain a mixed dry material; add the weighed magnesium sulfate, citric acid, and water into the stirring tank and stir until there is no obvious undissolved solids to obtain a mixed solution; then, while stirring, add the mixed solution to the mixed dry material and stir evenly to obtain a mixed material;

[0065] Paving: spread the mixture evenly in the mold to form a slab with a thickness of 2-30...

Embodiment 2

[0069] A kind of fireproof composite board base material, its raw material composition is,

[0070] Bamboo powder 370kg

[0071] Magnesium sulfate 160kg

[0072] Magnesium oxide 250kg

[0073] Perlite 10kg

[0074] Citric acid 60kg

[0075] 150kg of water.

[0076] The preparation method comprises the following steps,

[0077] Weighing: Weigh bamboo powder, magnesium sulfate, magnesium oxide, perlite, citric acid and water according to the above ratio;

[0078] Mixing material: add the weighed bamboo powder, magnesium oxide, and perlite into the powder mixer and mix evenly to obtain a mixed dry material; add the weighed magnesium sulfate, citric acid, and water into the stirring tank and stir until there is no obvious undissolved solids to obtain a mixed solution; then, while stirring, add the mixed solution to the mixed dry material and stir evenly to obtain a mixed material;

[0079] Paving: spread the mixture evenly in the mold to form a slab with a thickness of 2-30...

Embodiment 3

[0083] A kind of fireproof composite board base material, its raw material composition is,

[0084] Bamboo Powder 400kg

[0085] Magnesium sulfate 150kg

[0086] Magnesium oxide 200kg

[0087] Perlite 30kg

[0088] Sodium citrate 70kg

[0089] 150kg of water.

[0090] The preparation method comprises the following steps,

[0091] Weighing: Take bamboo powder, magnesium sulfate, magnesium oxide, perlite, sodium citrate and water according to the above ratio;

[0092] Mixing material: Add the weighed bamboo powder, magnesium oxide, and perlite into the powder mixer and mix evenly to obtain a mixed dry material; add the weighed magnesium sulfate, sodium citrate, and water into the stirring tank and stir until no Obvious undissolved solids are obtained to obtain a mixed solution; then, while stirring, the mixed solution is added to the mixed dry material and stirred evenly to obtain a mixed material;

[0093] Paving: spread the mixed material evenly in the mold to form a sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com