Cold-rolled steel sheet for thermoforming excellent in corrosion resistance and spot weldability, thermoformed part, and manufacturing method thereof

A technology for cold-rolled steel sheets and manufacturing methods, applied in the directions of manufacturing tools, metal rolling, furnace types, etc., can solve the problems of difficulty in ensuring corrosion resistance, reducing economy and productivity, and inability to ensure spot weldability, etc., to achieve excellent Effects of corrosion resistance and spot weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0146] A slab having a thickness of 40 mm having the composition shown in the following Table 1 was vacuum-dissolved, heated in a heating furnace at 1200° C. for 1 hour, and then finish-rolled at a finish rolling temperature of 900° C. to produce a final thickness of 3 mm. hot-rolled steel plate. The hot-rolled steel sheet was coiled at 600°C. Next, after pickling the hot rolled steel sheet, cold rolling was performed at a cold rolling reduction of 50%.

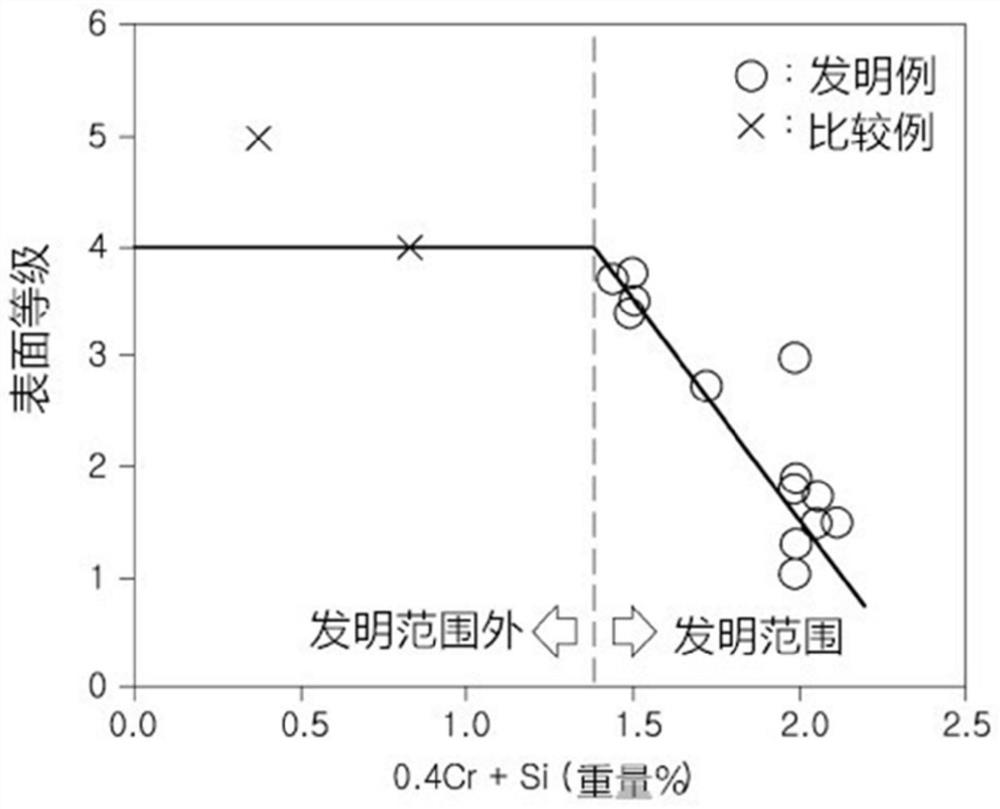

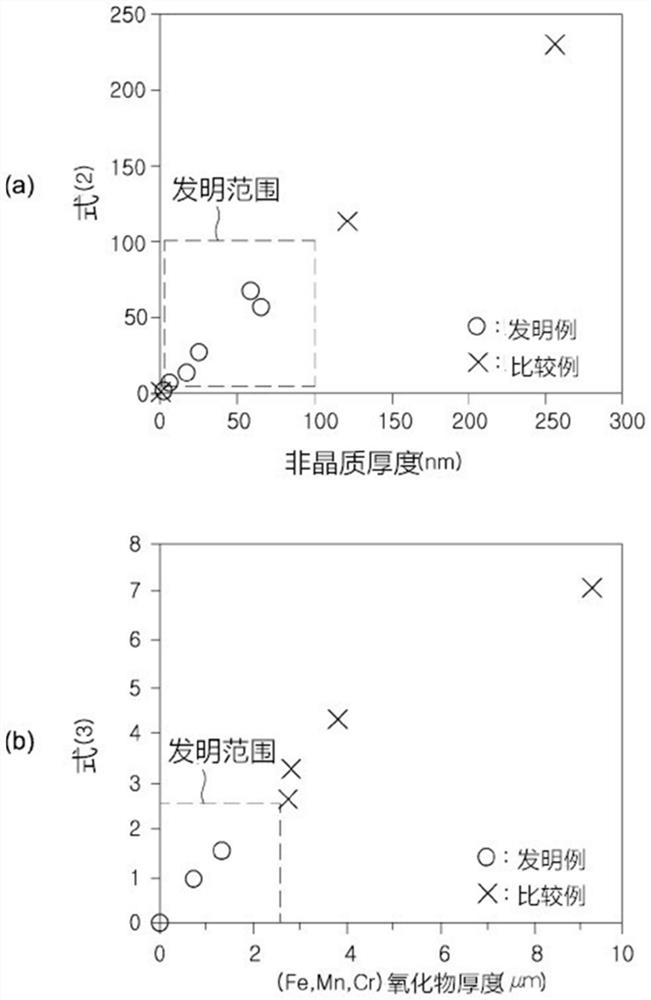

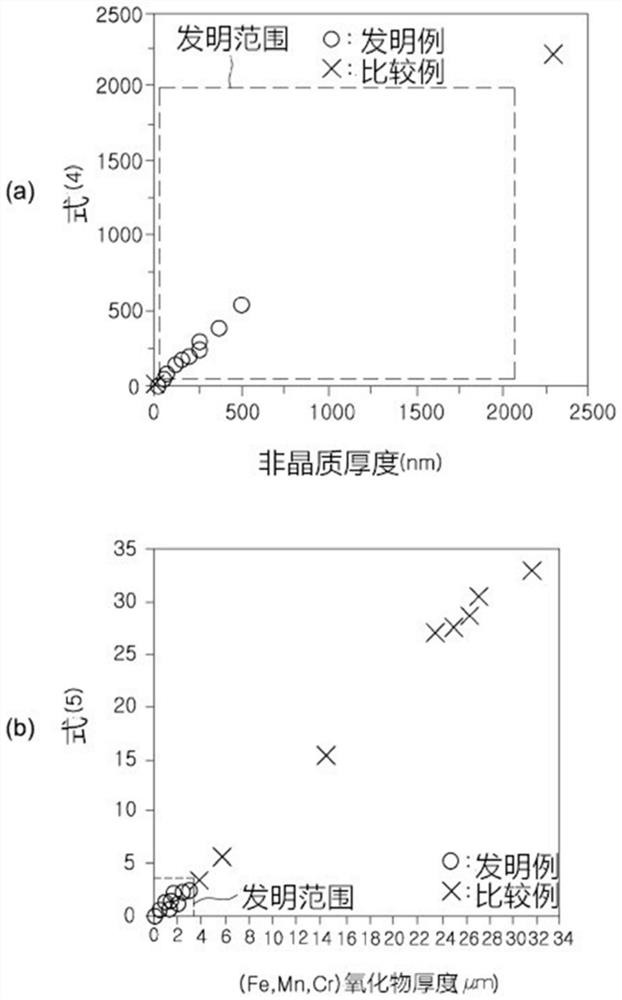

[0147] As shown in Table 2 below, using the cold-rolled steel sheets manufactured as described above, continuous annealing was performed at an annealing temperature of 780° C. and different dew point temperature conditions (DP(I)). The thicknesses of the Si amorphous oxide layer and the (Fe, Mn, Cr) oxide layer on the surface of the cold-rolled steel sheet were measured after continuous annealing, and are listed in Table 2. In addition, the values of the following formula (1) to formula (3) were calculated and described i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com