Preparation method of manyflower gueldenstaedtid herb formula granules with effects of clearing heat, removing toxins, cooling blood and diminishing swelling as well as formula granules prepared by method

A technology for formula granules, heat-clearing and detoxification, which is applied in the field of preparation of sweet ditin formula granules, and achieves the effects of easy storage, convenient taking and good granule forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

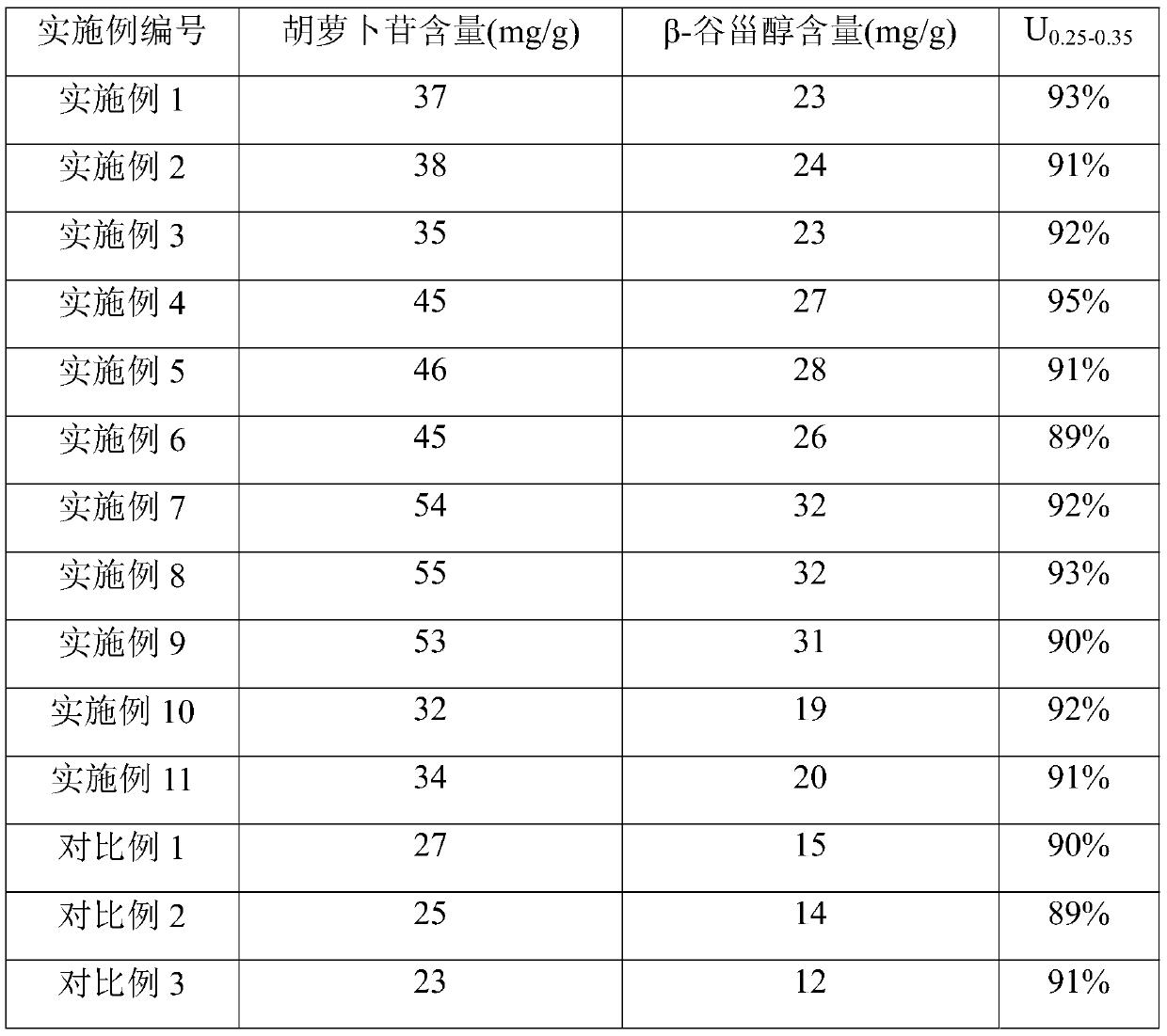

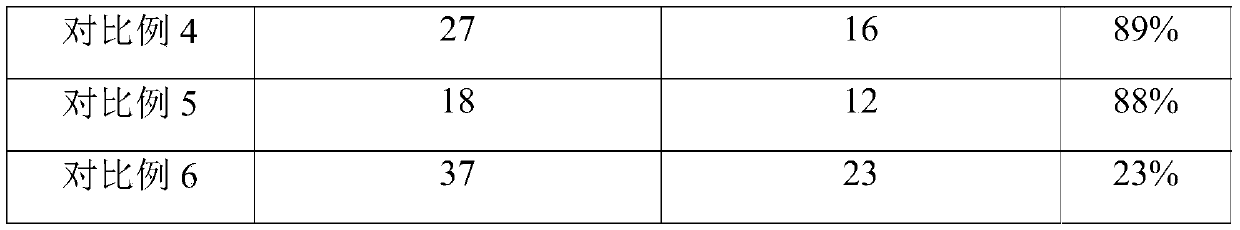

Examples

preparation example Construction

[0028] The preparation method of sweet ditin formula granule of the present invention comprises the following steps:

[0029] (1) Grinding the dried sweet ditin medicinal material to obtain a powder with a particle size of 40-100 mesh;

[0030] (2) Soak the powder obtained in step (1) with 2-5 times the volume of hot water;

[0031] (3) filter, the filter cake obtained is mixed with the aqueous ethanol solution of 15-20 times of volume of feeding amount;

[0032] (4) ultrasonic extraction 2-3 times;

[0033] (5) filter, and the filtrate is concentrated under reduced pressure to a concentrated solution whose relative density is 1.1-1.2;

[0034] (6) mixing the concentrate with pharmaceutically acceptable adjuvants;

[0035] (7) Freeze-drying, collecting the dry cream powder, pulverizing through an 80-mesh sieve, and mixing in a mixing tank;

[0036] (8) Granulate the obtained sweet-sweetened cream powder, and granulate the granules with a 20-mesh sieve and a 50-mesh sieve i...

Embodiment 1

[0052] (1) Take 1 kg of dried sweet ditin, crush it to 80 mesh, add 3 times the amount of hot water (50°C) to soak for 2 hours, filter it with 200 mesh stainless steel wire mesh, and mix the obtained filter cake with 18 times the amount of material mixed ethanol aqueous solution (concentration is 45% by weight), ultrasonically extracted 3 times under the ultrasonic frequency of 90kHz, each extraction was 45 minutes, filtered with 200-mesh stainless steel wire mesh, and the filtrate was concentrated under reduced pressure to a concentrated solution with a relative density of 1.15;

[0053] (2) Add 100g of a mixture of starch, lactose and dextrin (the weight ratio of the three is 1:0.25:1) to the concentrated solution for mixing, freeze-dry, collect the dry cream powder, crush it through an 80-mesh sieve, and mix it in a mixing tank ;

[0054] (3) Take the powder of sweet dithin paste, sieve and granulate the granules, and sieve the granules with a 20-mesh sieve and a 50-mesh si...

Embodiment 2

[0056](1) Take 1 kg of dried sweet ditin medicinal material, crush it to 100 mesh, soak it in hot water (40°C) with 4 times the feeding amount for 3 hours, filter it with 200 mesh stainless steel wire mesh, and mix the obtained filter cake with 16 times the feeding amount The ethanol aqueous solution (concentration is 35% by weight) is mixed, and ultrasonic extraction is carried out 3 times under the ultrasonic frequency of 90kHz, extracts 45 minutes each time, filters with 200 mesh stainless steel screens, and the filtrate is concentrated under reduced pressure to the concentrated solution that relative density is 1.16;

[0057] (2) Add 100g of a mixture of starch, lactose and dextrin (the weight ratio of the three is 1:0.25:1) to the concentrated solution for mixing, freeze-dry, collect the dry cream powder, crush it through an 80-mesh sieve, and mix it in a mixing tank ;

[0058] (3) Take the cinnamon paste powder, sieve and granulate the granules, and granulate the granule...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com