A kind of preparation method of two-dimensional temperature-sensitive metal-organic framework nanosheet-based filter membrane

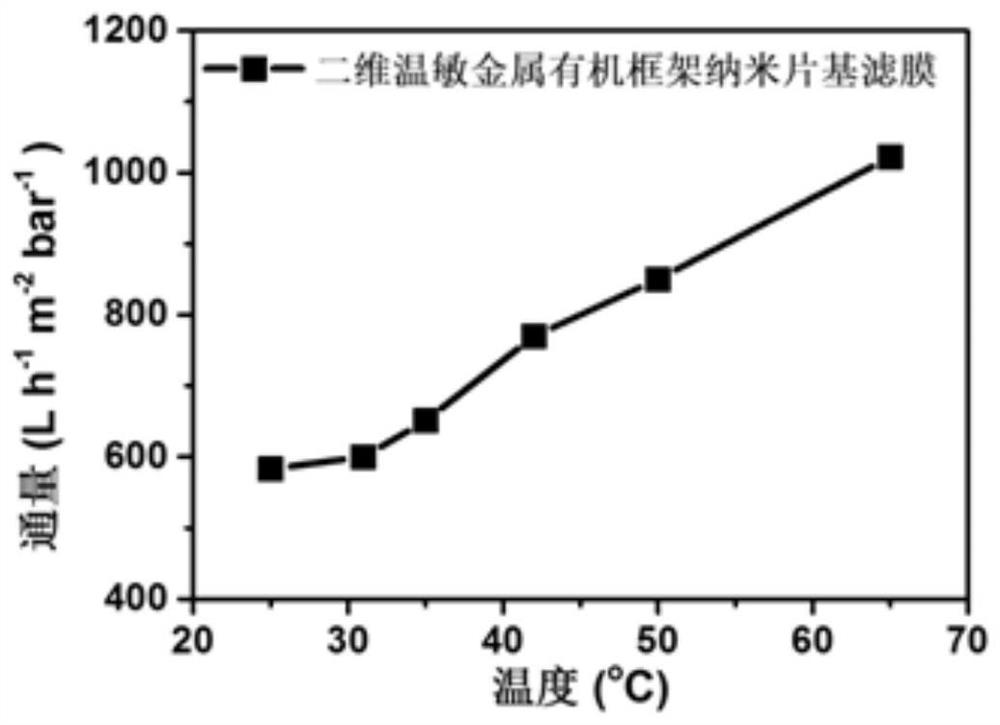

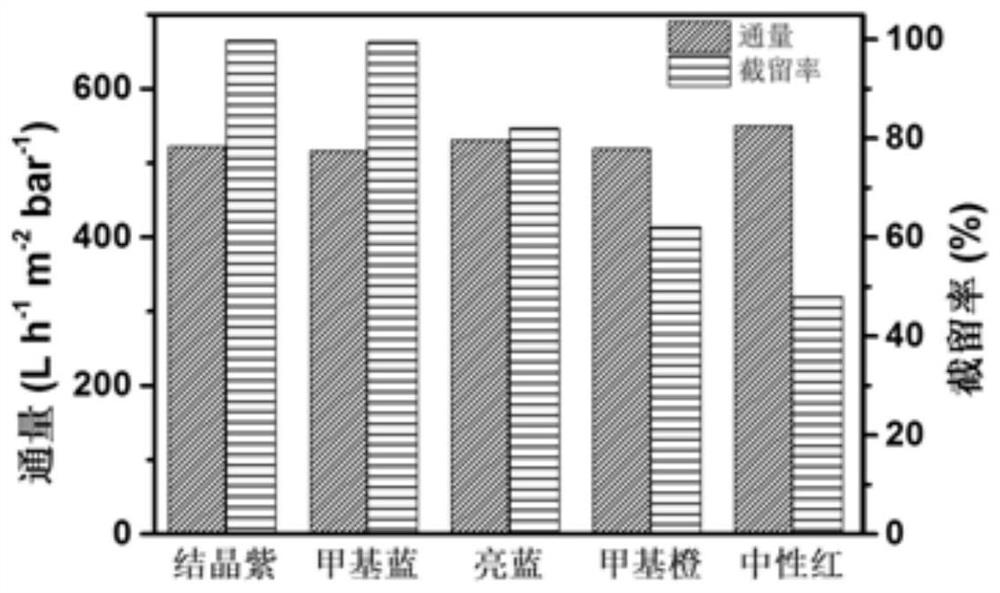

A technology of metal-organic frameworks and nanosheets, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as lack of intelligent response performance, and achieve excellent separation performance, high throughput, high retention, high The effect of porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) 20 g of zinc nitrate, 3.6 g of pyrazine, 80 g of polyvinylpyrrolidone / polyvinylhexamide (mass 3 / 1, polyvinylpyrrolidone molecular weight 30000-40000, is purchased from Aladdin Company; polyvinylhexhalanamide molecular weight 4000 -6000, by free radical polymeridinol-acamlamide, raw materials were purchased from Aladdin Company) dissolved in 36L dimethylformamide / ethanol (volume ratio 3 / 1) mixed solvent to obtain solution A.

[0034] (2) 12 g of four (4-carboxyphenyl) porphin is dissolved in 12L dimethylformamide / ethanol (volume ratio 3 / 1) mixed solvent to obtain solution B.

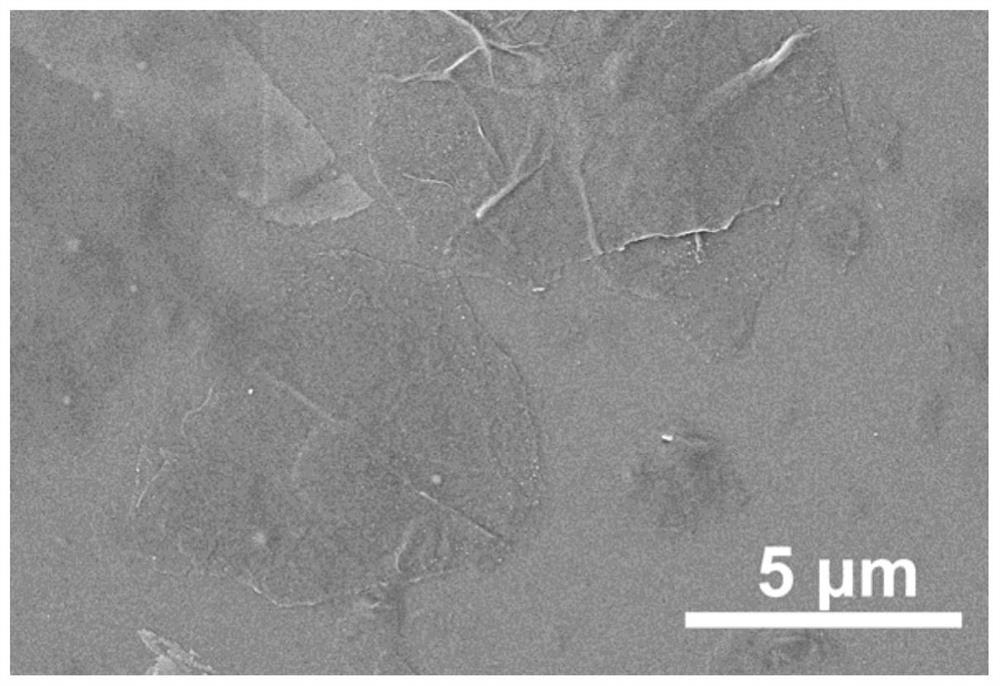

[0035] (3) Mix the solution A with the solution B, soon 30 min, then the heat reaction was 16 h at an 80 ° C solvent. The product was washed 3 times with ethanol to give a surface-modified two-dimensional temperature-sensitive metal organic frame nanofer with a polymer.

[0036] (4) The film was prepared on the cellulose base film (purchased from Millipore, aperture 200 μm) using a two-dimens...

Embodiment 2

[0040] (1) 10 g of zinc chloride, 1.8 g pyrazine, 50 g of polyvinylpyrrolidone / polyvinylhexamide (mass ratio 2 / 1, polyvinylpyrrolidone molecular weight 8000-12000, is purchased from Aladdin Company; polyvinylhexamide molecular weight 2000-3000, by free radical polymerous achexhelated lactam, raw materials were purchased from Aladdin Company) to dissolve in 18 L Dimethylformamide / ethanol (volume ratio 3 / 1) mixed solvent to obtain solution A.

[0041] (2) 6 g of four (4-carboxybar) porphin is dissolved in 6L dimethylformamide / ethanol (volume ratio 3 / 1) mixed solvent to obtain solution B.

[0042] (3) Mix the solution A with the solution B, soon 30 min, then the heat reaction was thermally reacted at 80 ° C. The product was washed 3 times with ethanol to give a surface-modified two-dimensional temperature-sensitive metal organic frame nanofer with a polymer.

[0043] (4) The film was prepared on the nylon base film (purchased from Millipore, aperture 200 μm) using a two-dimensi...

Embodiment 3

[0047] (1) 40 g of zinc acetate, 8 g pyrazine, 200 g of polyisopropyl acrylamide / polyvinylhexamide (mass ratio 1 / 4, polyisopropyl acrylamide molecular weight 8000-12000, by free radical poly] Home purchase from Aladdin; polyvinylhexamide molecular weight 2000-3000, by free radical polymerous achexhelated lactam, raw materials are purchased from Aladdin Company) mixed at 72L dimethylformamide / ethanol (volume ratio 3 / 1) Dissolve in the solvent to obtain a solution A.

[0048] (2) 25 g of tetra (4-carboxybar) porphin is dissolved in 30 l Dimethylformamide / ethanol (volume ratio 3 / 1) mixed solvent to obtain solution B.

[0049] (3) Mix the solution A with solution B, soon 30 min, then the heat reaction was heat 15 h at a solvent at 80 ° C. The product was washed 3 times with ethanol to give a surface-modified two-dimensional temperature-sensitive metal organic frame nanofer with a polymer.

[0050] (4) The film was prepared on a polycarbonate base film (purchased from Millipore, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com