Liquid metal wire for 3D printing and preparation method thereof

A liquid metal, 3D printing technology, applied in the field of 3D printing, can solve the problems that liquid metal cannot be applied to 3D printers and cannot be applied on a large scale, so as to suppress dynamic recovery or recrystallization, improve strength and mechanical properties, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

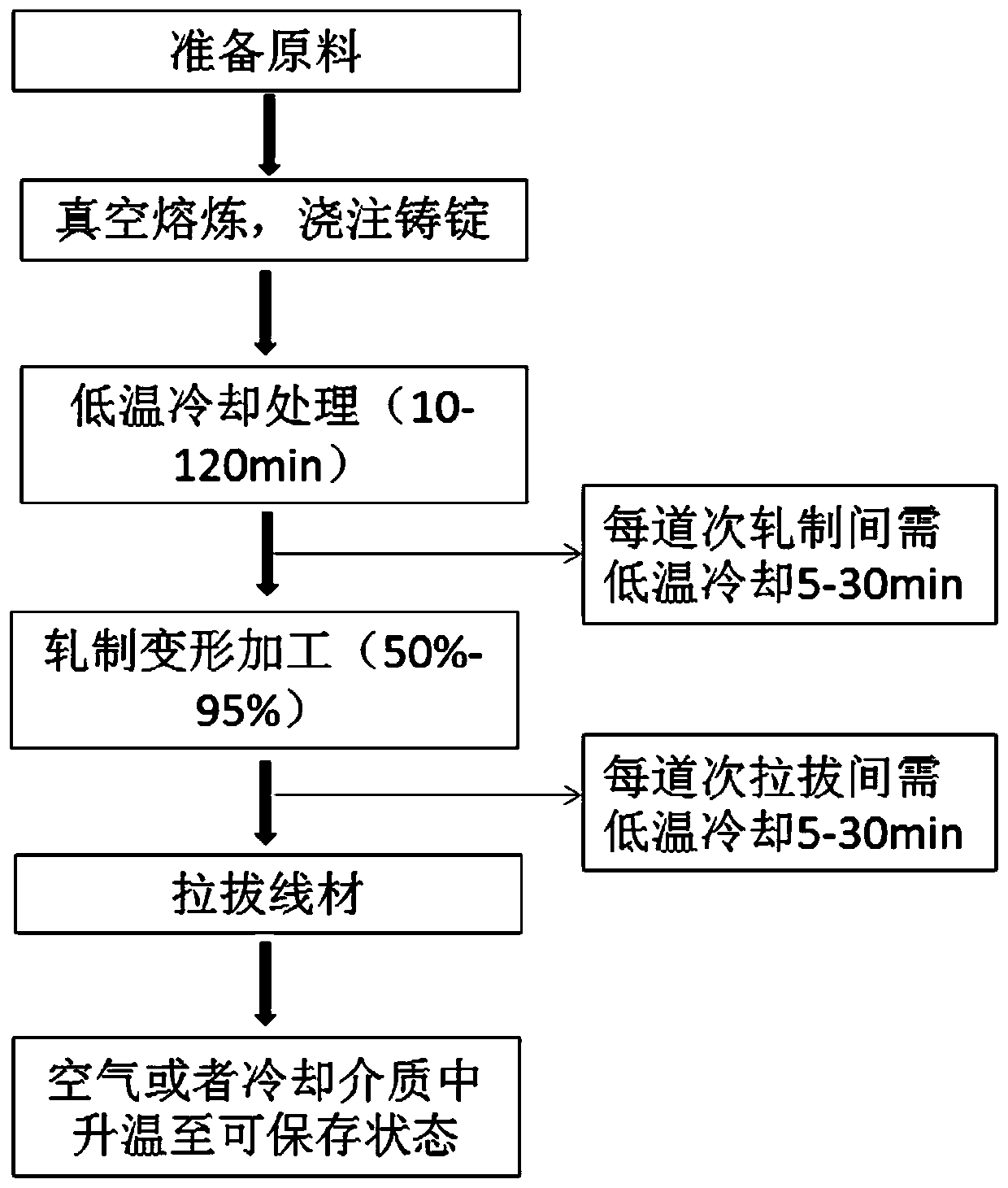

[0041] This embodiment relates to a method for preparing a liquid metal wire, comprising the following steps (see the flow chart for the figure 1 ):

[0042] 1) Mix pure bismuth, indium, tin and zinc metals in a mass ratio of 35:48.6:15.9:0.4 to prepare 1kg of raw materials with an alloy melting point of about 58°C, and then place the raw materials in a vacuum melting furnace and heat them to 200°C for melting , and the solution was stirred occasionally. Keep argon flowing during the entire stirring process to avoid oxidation of the melt; after melting, cast the alloy into a round rod with a diameter of 20mm, and place the round rod in liquid nitrogen to cool until the temperature is -10°C;

[0043] 2) After the cooling treatment, the round bar is passed through a rolling mill to roll the alloy into a bar with a diameter of 6mm, and the rolling deformation of each pass is 15%, and the bar should be put back into liquid nitrogen for low-temperature heat preservation between pa...

Embodiment 2

[0046] This embodiment relates to a method for preparing a liquid metal wire, comprising the following steps:

[0047]1) Prepare pure bismuth, indium and tin metal with a mass ratio of 53.6:30.3:16.1 to make 1 kg of raw material with an alloy melting point of about 83°C, then place the raw material in a vacuum melting furnace and heat it to 300°C for melting, and occasionally smelt the solution Stir. Keep argon flowing throughout the stirring process to avoid oxidation of the melt. After the smelting is completed, the alloy is cast into a round rod with a diameter of 20mm, and the round rod is cooled in liquid nitrogen until the temperature is -20°C;

[0048] 2) The processed round bar is passed through a rolling mill to roll the alloy into a bar with a diameter of 4 mm, and the rolling deformation in each pass is 10%, and the bar should be put back into liquid nitrogen for low-temperature heat preservation between passes. In order to avoid the reduction of bar strength caus...

Embodiment 3

[0051] This embodiment relates to a method for preparing a liquid metal wire, comprising the following steps:

[0052] 1) Prepare 1 kg of raw material with an alloy melting point of about 74°C with pure bismuth and indium metal at a mass ratio of 34:66, then place the raw material in a vacuum melting furnace and heat it to 230°C for melting, and stir the solution from time to time. Keep argon flowing throughout the stirring process to avoid oxidation of the melt. After the smelting is completed, the alloy is cast into a round rod with a diameter of 20mm, and the round rod is cooled in liquid nitrogen until the temperature is -30°C;

[0053] 2) The processed round bar is passed through a rolling mill to roll the alloy into a bar with a diameter of 8 mm, and the rolling deformation in each pass is 5%, and the bar should be put back into liquid nitrogen for low-temperature heat preservation between passes. In order to avoid the reduction of bar strength caused by the increase of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com