A new welding method with two-wire four-pulse robot

A welding method and pulse welding technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of large spatter, reduce arc force, etc., achieve beautiful shape, increase penetration ability, and reduce crack sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

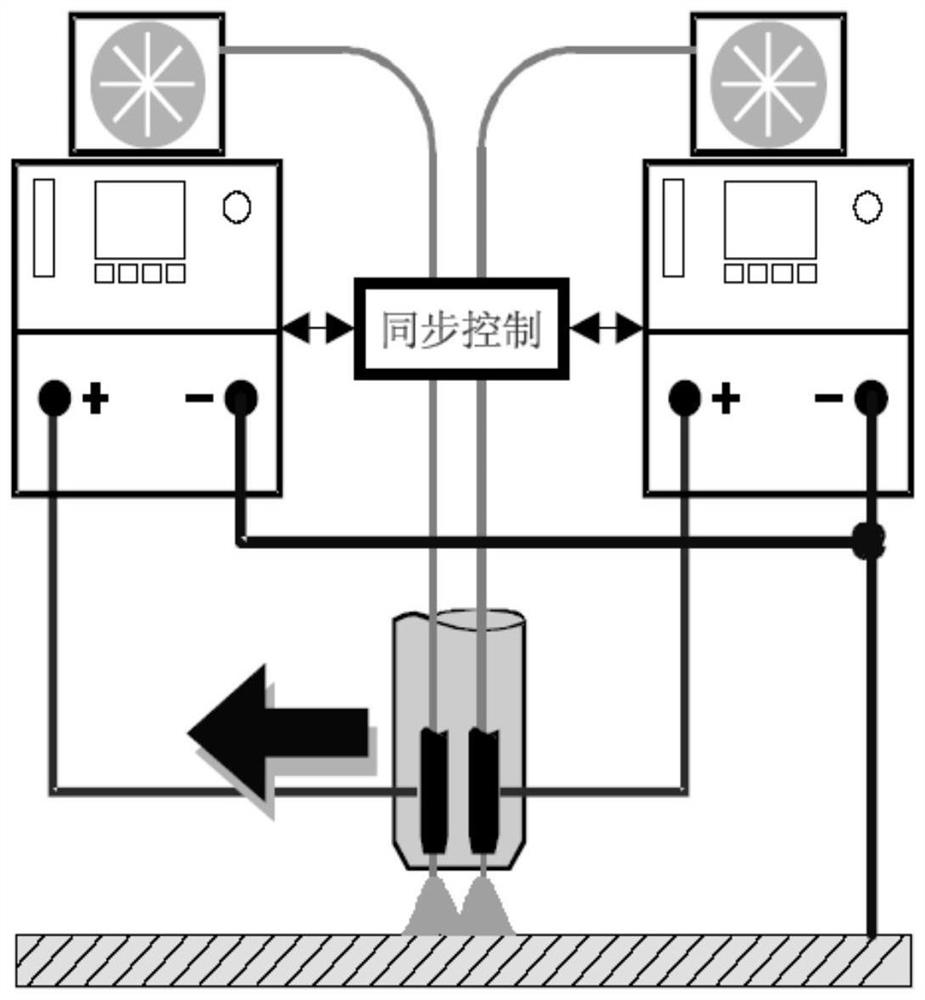

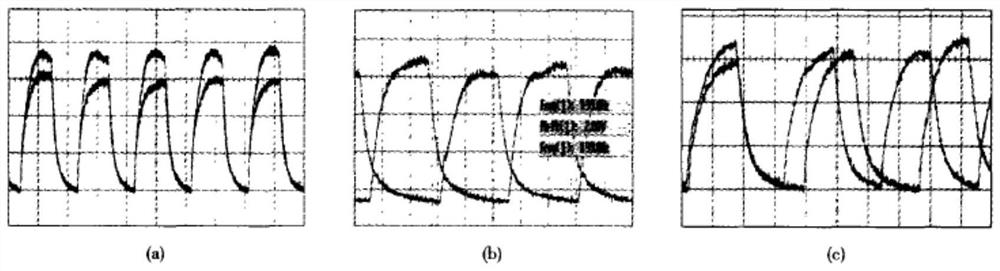

[0028] The present embodiment proposes a double-wire four robot novel pulse welding method, the robot control means comprises a wire feed member, and pulse welding power supply torch, the method comprises two mutual communication, the two wires wire feeding member arranged at an angle toward the longitudinal welding position; the control unit controls the two pulse welding power supply so that the current larger than the current provided by the filament forward rearward wire supplied; and said control means further controls the transmission wire means to provide the same or different front and rear wire filament wire feed speed, and controlling the use of four separate pulse welding power supply to provide a pulse current to the welding wire.

[0029] Wherein said control means is a microcontroller system. Material in the two wire embodiment of the present embodiment, the diameter, the same or different wire feed speeds. The two wires of the wire feed speed changes such that two w...

Embodiment 2

[0031] The present embodiment proposes a double-wire four robot novel pulse welding method, the robot control means comprises a wire feed member, and pulse welding power supply torch, the method comprises two mutual communication, the two wires wire feeding member arranged at an angle toward the longitudinal welding position; the control unit controls the two pulse welding power supply so that the current larger than the current provided by the filament forward rearward wire supplied; and said control means further controls the transmission wire means to provide the same or different front and rear wire filament wire feed speed, and controlling the use of four separate pulse welding power supply to provide a pulse current to the welding wire.

[0032] Wherein said control means is a microcontroller system. Material in the two wire embodiment of the present embodiment, the diameter of the wire feed speed may be different. The two wires of the wire feed speed changes such that two w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com