A degradable and recyclable hyperbranched epoxy resin and its preparation method and application

A technology of epoxy resin and hyperbranched polymer, applied in the direction of epoxy resin glue, epoxy resin coating, adhesive type, etc., can solve the problems of long time consumption, long cycle, small application range, etc., and achieve simple preparation process , low cost of raw materials, strong effect of pencil hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

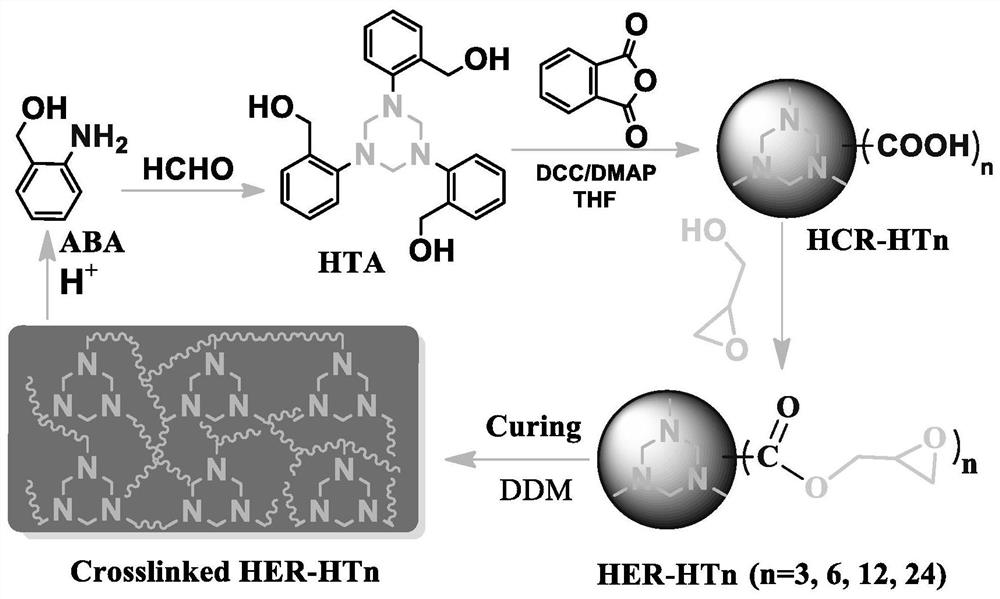

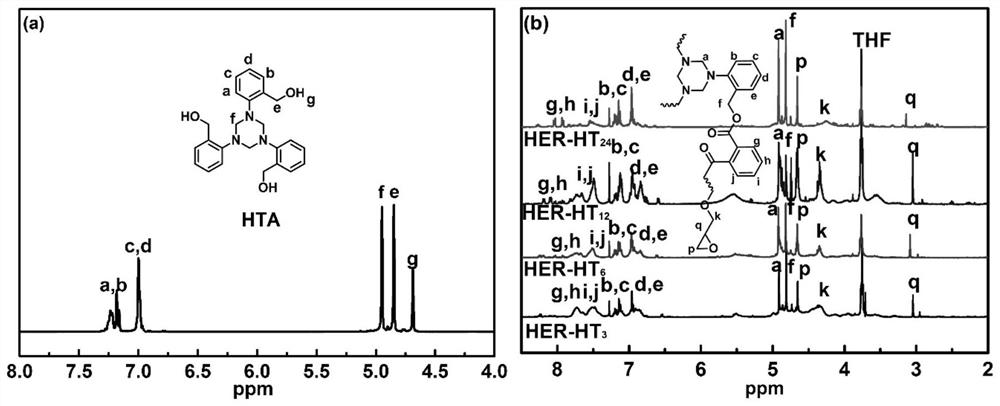

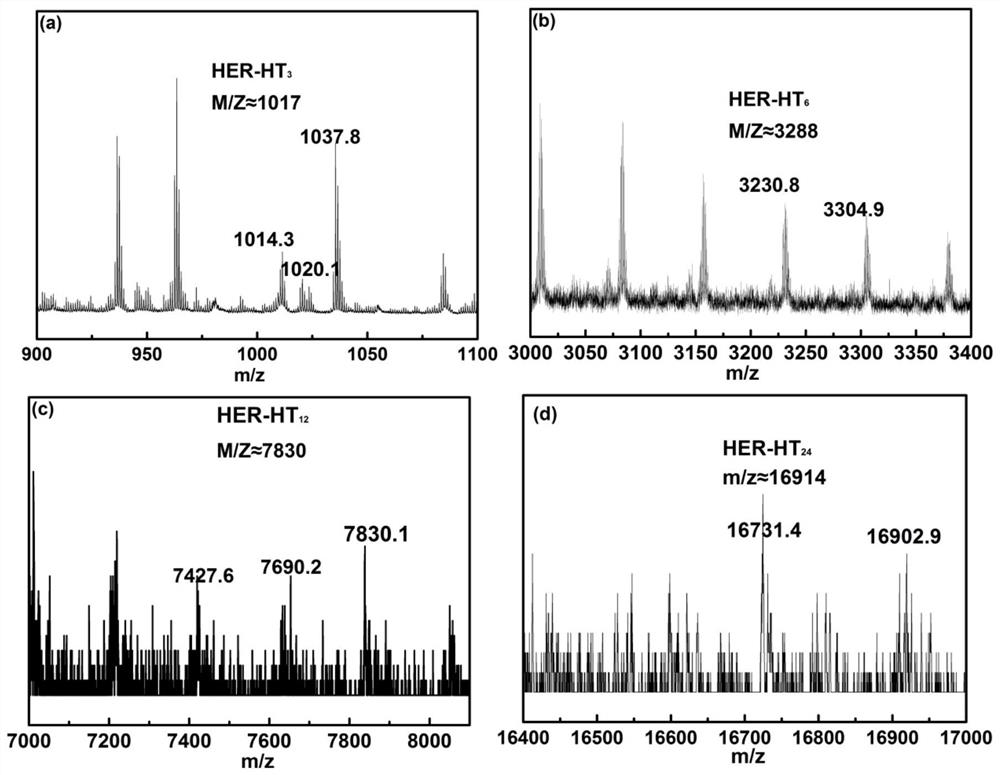

[0063] This embodiment provides a method for preparing a degradable and recyclably synthesized hyperbranched epoxy resin, and a method for degrading and recycling, including the following steps:

[0064] (a) Add 0.1mol 1,3,5-tribenzyl alcohol-based hexahydro-s-triazine HTA, 0.3mol phthalic anhydride, 1mol tetrahydrofuran, 0.1mol p-toluenesulfonic acid pyridinium salt, 4-dimethylaminopyridine (4- Dimethylaminopyridine (0.5% of the total mass of HTA and phthalic anhydride) was mixed evenly, stirred and reacted at 25°C for 24h, filtered at low temperature, and then the solvent tetrahydrofuran was vacuum-extracted at about 40°C to obtain a carboxyl-terminated hyperbranched polymer (HCR-HT1, Each mole of HCR-HT1 contains 3 moles of carboxyl groups), and the number average molecular weight is about 849 g / mol.

[0065] (b) Add 0.01mol HCR-HT1, 0.03mol glycidol, 0.01mol p-toluenesulfonate pyridinium salt, 4-dimethylaminopyridine (4-dimethylaminopyridine is 0.5% of the total mass of HT...

Embodiment 2

[0069] This embodiment provides a method for preparing a degradable and recyclably synthesized hyperbranched epoxy resin, and a method for degrading and recycling, including the following steps:

[0070] (a) Add 0.4mol 1,3,5-tribenzyl alcohol-based hexahydro-s-triazine HTA, 0.9mol phthalic anhydride, 4mol tetrahydrofuran, 0.9mol p-toluenesulfonic acid pyridinium salt, 4-dimethylaminopyridine (4- Dimethylaminopyridine (0.5% of the total mass of HTA and phthalic anhydride) was mixed evenly, stirred and reacted at 25°C for 24h, filtered at low temperature, and then the solvent tetrahydrofuran was vacuum-extracted at about 40°C to obtain a carboxyl-terminated hyperbranched polymer (HCR-HT2, Each mole of HCR-HT2 contains 6 moles of carboxyl groups), and the number average molecular weight is about 2898 g / mol.

[0071] (b) Add 0.01mol HCR-HT2, 0.06mol glycidol, 0.06mol p-toluenesulfonate pyridinium salt, 4-dimethylaminopyridine (4-dimethylaminopyridine is 0.5% of the total mass of H...

Embodiment 3

[0075] This embodiment provides a method for preparing a degradable and recyclably synthesized hyperbranched epoxy resin, and a method for degrading and recycling, including the following steps:

[0076] (a) Add 0.1mol 1,3,5-tribenzyl alcohol-based hexahydro-s-triazine HTA, 0.21mol phthalic anhydride, 1mol tetrahydrofuran, 0.21mol p-toluenesulfonic acid pyridinium salt, 4-dimethylaminopyridine (4- Dimethylaminopyridine (0.5% of the total mass of HTA and phthalic anhydride) was mixed evenly, stirred and reacted at 25°C for 24h, filtered at low temperature, and then the solvent tetrahydrofuran was vacuum-extracted at about 40°C to obtain a carboxyl-terminated hyperbranched polymer (HCR-HT3, Each mole of HCR-HT3 contains 12mol carboxyl groups), and the number average molecular weight is about 6996g / mol.

[0077] (b) Add 0.01mol HCR-HT3, 0.12mol glycidol, 0.12mol p-toluenesulfonate pyridinium salt, 4-dimethylaminopyridine (4-dimethylaminopyridine is 0.5% of the total mass of HTA a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com