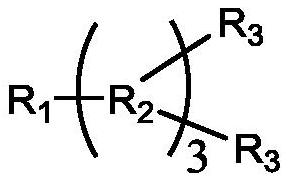

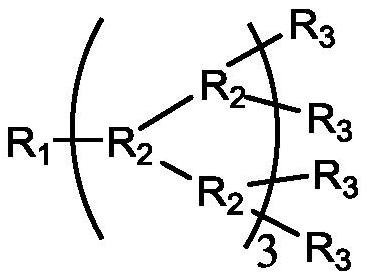

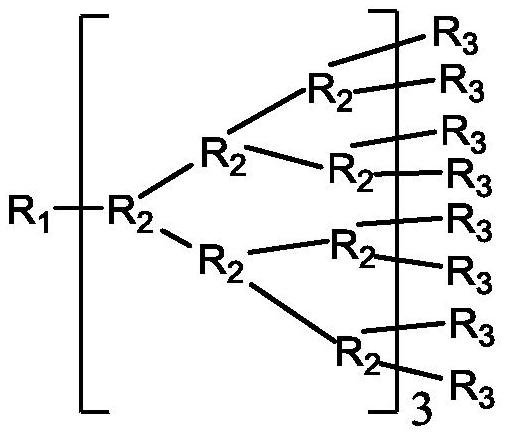

Bio-based degradable hyperbranched epoxy resin and preparation method thereof

An epoxy resin, bio-based technology, applied in the direction of epoxy resin coating, coating, plastic recycling, etc., can solve the problems of difficult degradation of epoxy resin, unfavorable sustainable development, etc., achieve low raw material cost, reduce viscosity, relatively The effect of low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A bio-based degradable hyperbranched epoxy resin, the preparation method steps are as follows:

[0052] Add 0.4mol of trimethylolpropane and 0.3mol of 2,5-furandicarboxylic acid to a four-necked flask equipped with a condenser, stirrer, water separator and thermometer in sequence, then add 100g of xylene and 0.5g of p- Toluenesulfonic acid. in N 2 Under the atmosphere, heat to 140°C and stir for 20 hours to react. The test acid value is about 9 mgKOH / g to stop the reaction, and the temperature is lowered to 100°C. Add 0.7mol thioglycolic acid, stir and react at 100°C for 20 hours under N2 atmosphere, and remove the water-carrying agent and excess thioglycolic acid in vacuum while hot. Then add 45g of dioxane and 45g of dichloromethane, after fully dissolving, gradually lower the temperature to room temperature. Then add 0.5g benzophenone and 0.7mol glycidyl methacrylate, react under 800W ultraviolet light for 20 minutes at room temperature, and vacuum out the organic...

Embodiment 2

[0054] A bio-based degradable hyperbranched epoxy resin, the preparation method steps are as follows:

[0055] Add 0.1mol trimethylolpropane and 0.09mol dimethyl 2,5-furandicarboxylate successively into a four-necked flask equipped with a condenser, agitator, water separator and thermometer, then add 40g xylene, 40g toluene, 0.65g tetrabutyl titanate. Heat to 170°C under N2 atmosphere and stir for 10 hours to react. The test acid value is about 8 mgKOH / g to stop the reaction, and the temperature is lowered to 120°C. Add 0.15mol mercaptopropionic acid, in N 2 Under atmosphere, stir and react at 120°C for 10 hours, remove the water-carrying agent and excess mercaptopropionic acid in vacuum while hot. Then add 13g of toluene and 15g of tetrahydrofuran, after fully dissolving, gradually lower the temperature to room temperature. Then add 0.03g of 2-methyl-1-[4-(methylthio)phenyl]-2-(4-morpholino)-1-acetone and 0.15mol glycidyl acrylate, at room temperature React with 3000W ult...

Embodiment 3

[0057] A bio-based degradable hyperbranched epoxy resin, the preparation method steps are as follows:

[0058] Add 0.22mol of trihydroxyethyl isocyanurate and 0.21mol of dibutyl 2,5-furandicarboxylate into a four-necked flask equipped with a condenser, agitator, water separator and thermometer in sequence, and then add 260g xylene, 1.25g zinc acetate. Heat to 160°C under N2 atmosphere and stir for 15 hours to react. The test acid value is about 9 mgKOH / g to stop the reaction, and the temperature is lowered to 110°C. Add 0.4mol mercaptopropionic acid, in N 2 Stir and react at 115°C for 15 hours under atmosphere, remove the water-carrying agent and excess mercaptopropionic acid in vacuum while hot. Then add 100g of dioxane and 80g of ethyl acetate, and after fully dissolving, gradually lower the temperature to room temperature. Then add 0.5g of 2-methyl-1-[4-(methylthio)phenyl]-2-(4-morpholino)-1-propanone and 0.33mol allyl glycidyl ether, at room temperature Under the condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com