Binary synergistic flame retardant system and application thereof

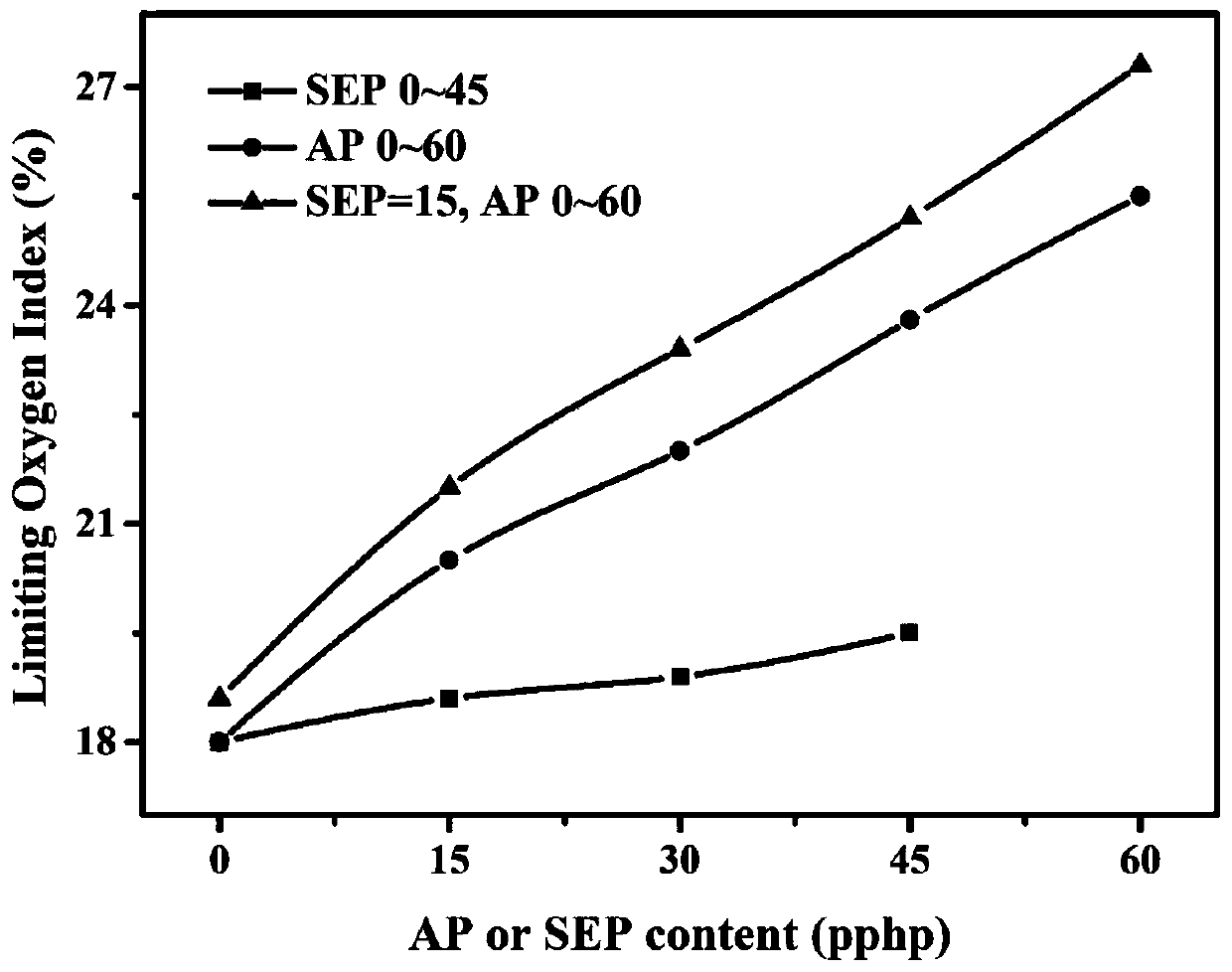

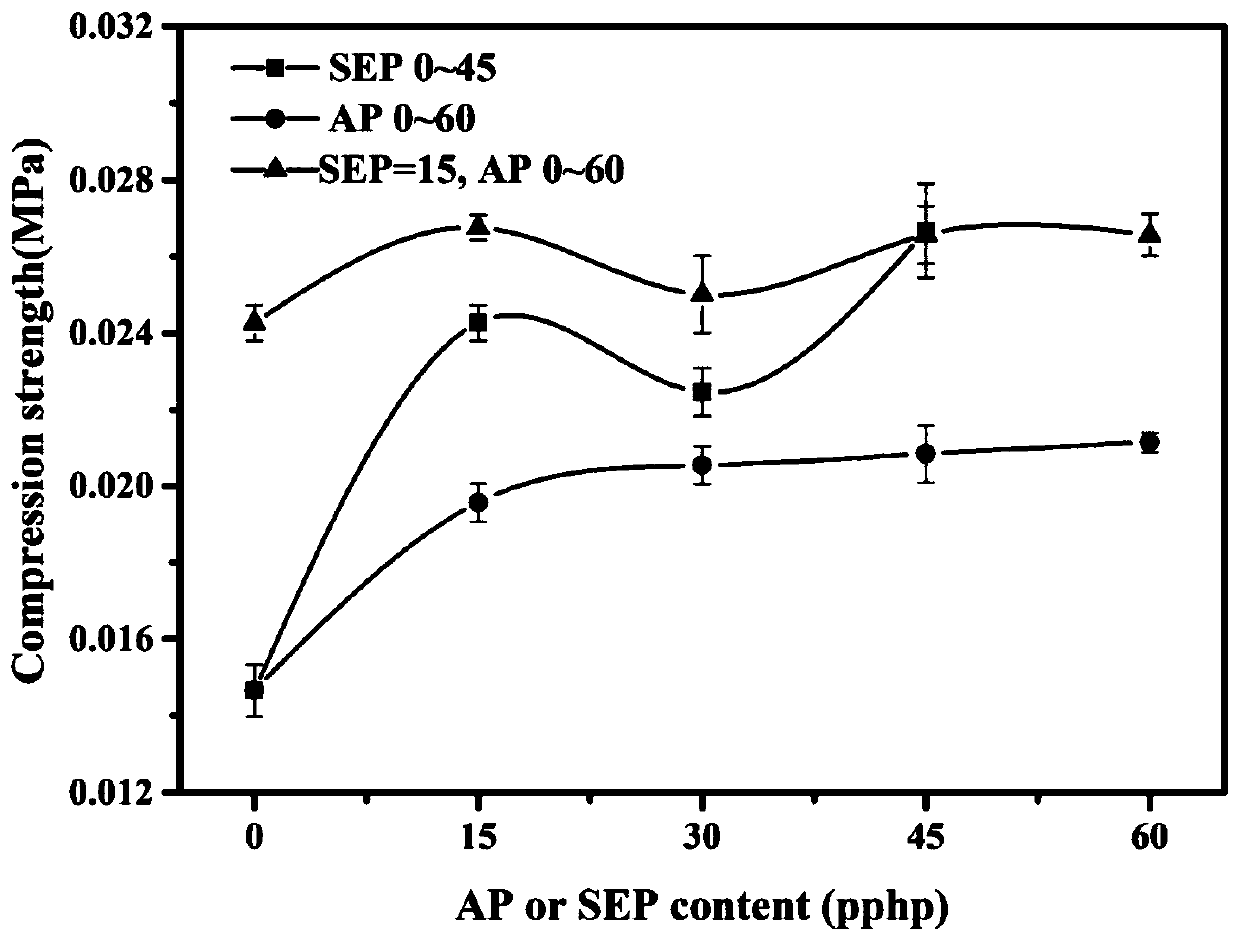

A synergistic flame retardant and system technology, applied in the field of flame retardant materials, can solve the problems of low flame retardant efficiency, high open cell ratio, and affecting the foam molding process of a single flame retardant, achieve good physical and mechanical properties, improve compressive strength, The effect of excellent flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0022] Examples 1-4 The polyurethane foam composite material prepared by the binary synergistic flame retardant system of the present invention

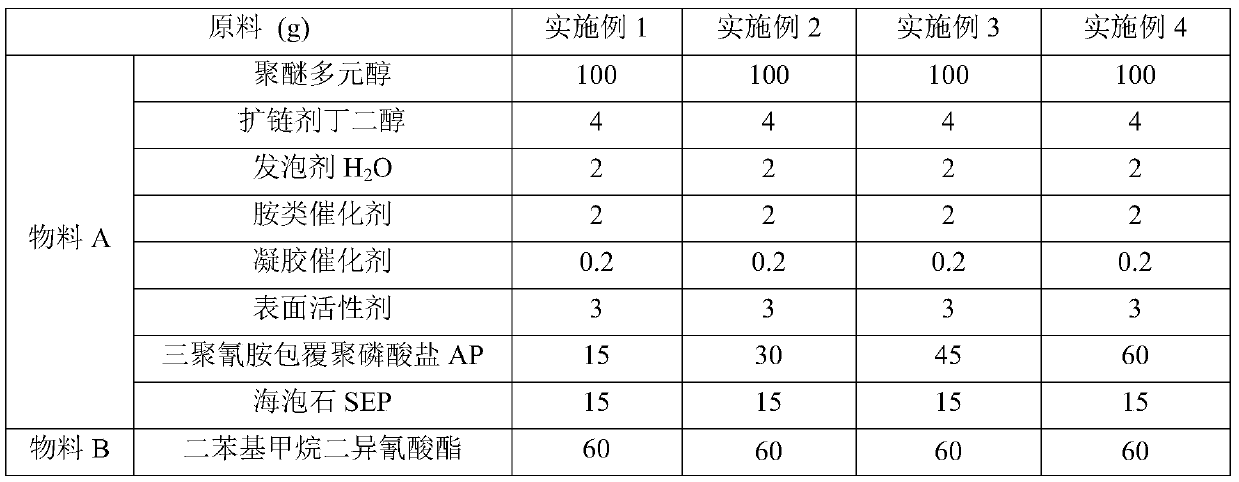

[0023] 1. Raw material ratio

[0024] Table 1 Raw Material Proportion of Embodiments 1 to 4 of the present invention

[0025]

[0026] In the table, the structural formula of polyether polyol is (Molecular weight is 4000, hydroxyl value is 27~29mgKOH / g); the structural formula of chain extender butanediol is HOH 2 C-CH 2 CH 2 -CH 2 OH; the amine catalyst is configured by 33% triethylenediamine and 67% dipropylene glycol, wherein the structural formula of triethylenediamine is The structural formula of dipropylene glycol is The gel catalyst is dibutyltin dilaurate, the structural formula is Surfactant is silicone oil DC193.

[0027] 2. Preparation method

[0028] Weigh each component according to the raw material ratio shown in Table 1, put material A in a container and mix, and stir evenly with a high-speed machine at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com