Solvent-free epoxy intumescent fireproof coating and preparation method thereof

A kind of technology of fireproof coating and expansion type, applied in the direction of fireproof coating, epoxy resin coating, anticorrosion coating, etc., can solve the problems of loss of practical applicability of fireproof coating, easy hydrolysis, etc., achieve excellent fire resistance reliability, excellent moisture and heat resistance, The effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

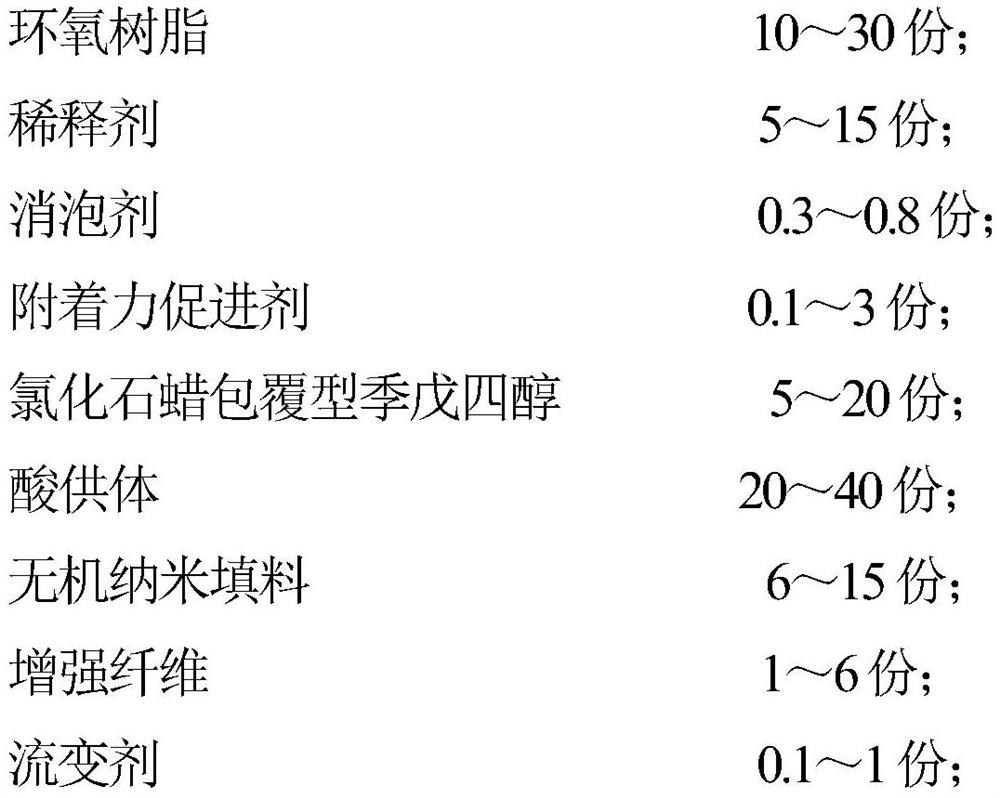

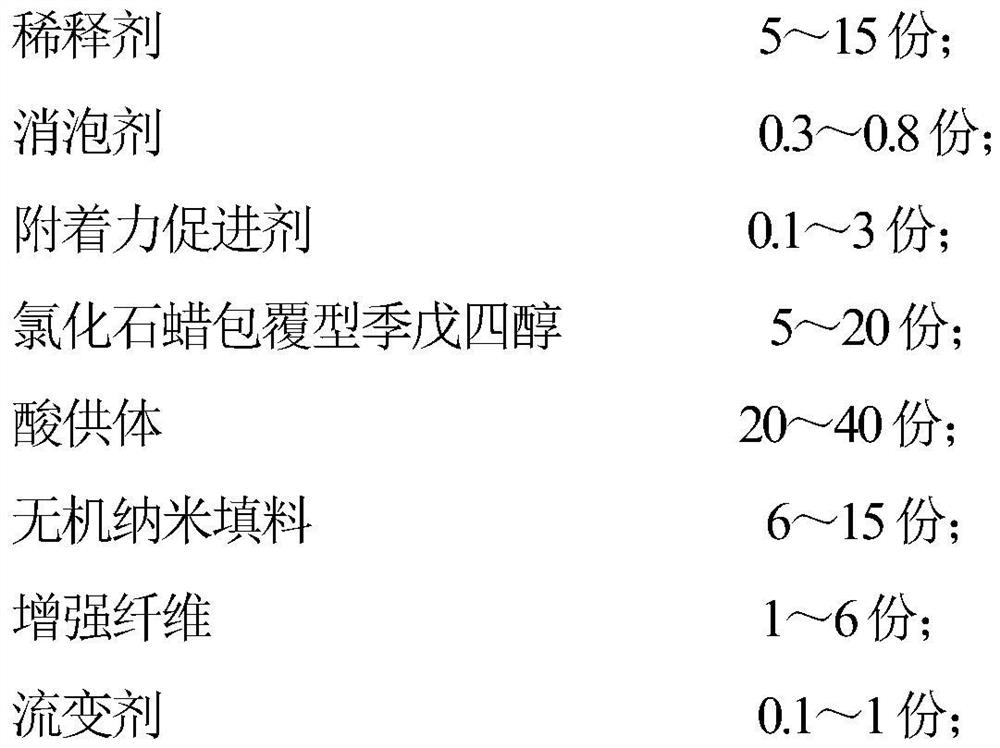

Method used

Image

Examples

Embodiment 1

[0060] In the present embodiment, the preparation method of chlorinated paraffin-coated pentaerythritol is as follows:

[0061] (1) Put a specified amount of chlorinated paraffin CP-70 (20% by mass) into propylene glycol butyl ether and ExxsolD30 mass ratio 1:1 mixed solvent (80% by mass) under the stirring condition of 300rpm speed, Stir until the chlorinated paraffin is completely dissolved to obtain a chlorinated paraffin solution with a mass fraction of 20%.

[0062] (2) Put the pentaerythritol powder of the formula amount into the chlorinated paraffin solution with a mass fraction of 20% under the stirring condition of 500rpm, then increase the speed to 1800rpm and stir for 30 minutes until the mixture is uniform.

[0063] (3) The obtained mixture was rotary evaporated at 60° C. to remove the mixed solvent and placed in an oven for thorough drying to obtain an evaporation residue, namely: a mixture of pentaerythritol coated with chlorinated paraffin.

[0064] (4) Grindin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com