Halogen-free phosphate-free environment-friendly synergistic flame retardant and use thereof

A synergistic flame retardant and synergistic flame retardant technology, which is applied in the field of flame retardants, can solve the problems of insignificant synergistic effect, loose combination, slipping processing of extruder screw, etc., and achieve excellent synergistic flame retardant effect. , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

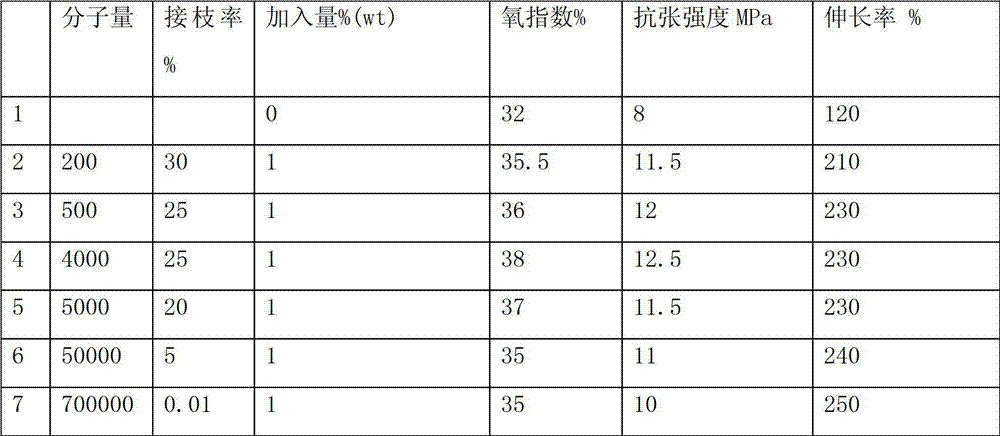

Embodiment 1-7

[0051] Raw material description:

[0052] PE: Polyethylene

[0053] EVA: Ethylene-vinyl acetate copolymer

[0054] POE: polyolefin elastomer

[0055] PE+EVA+POE mixture: a mixture of PE, EVA, and POE at a mass ratio of 25:52:23

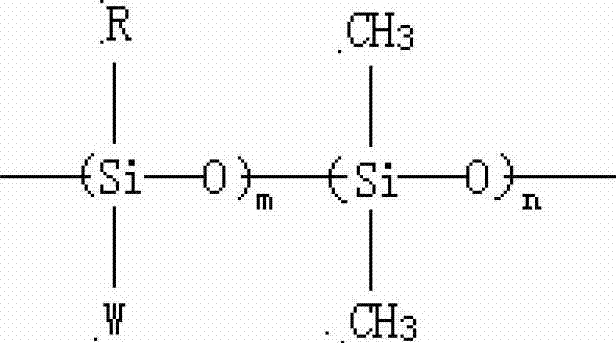

[0056] In the structural unit of the graft-modified polysiloxane used, R is a methoxyl group, and W is a phenyl group

[0057] The preparation method of graft modified polysiloxane:

[0058] Octamethylcyclotetrasiloxane plus sulfuric acid ring-opening and phenyltrimethoxysilane are obtained through equilibrium polymerization. The grafting rate and weight average molecular weight are controlled by conventional methods in the field, and the weight average molecular weight is measured by GPC.

[0059] The conditions for the preparation of graft-modified polysiloxane in this example and the following examples all adopt the conventional conditions of ring-opening polymerization in the art.

[0060] experiment method:

[0061] Mix (PE+EVA+POE) mixture...

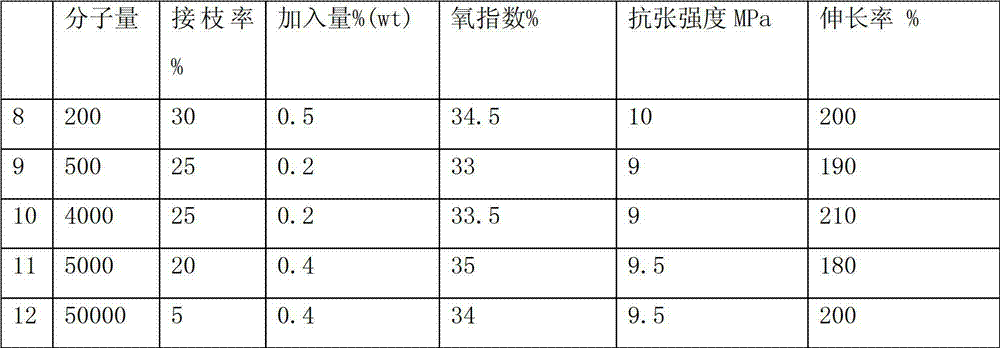

Embodiment 8-13

[0066] experiment method:

[0067] Mix (PE+EVA+POE) mixture with Al(OH) 3 Mix evenly in a high-speed mixer or internal mixer at a weight ratio of 4:6, add the above-mentioned graft-modified polysiloxane, continue to mix evenly and granulate to prepare low-smoke and halogen-free cable materials, inject into standard samples to measure oxygen index and Mechanical properties parameters.

[0068]

[0069]

[0070] *Addition % refers to the weight percentage of graft-modified polysiloxane in Al(OH)3.

Embodiment 14-20

[0072] experiment method:

[0073] Mix (PE+EVA+POE) mixture and inorganic flame retardant in a high-speed mixer or internal mixer at a weight ratio of 4:6, add graft-modified polysiloxane, continue to mix and granulate to prepare low-smoke Halogen-free cable material, injected into a standard sample to measure the oxygen index and mechanical performance parameters.

[0074]

[0075] *Addition % refers to: graft modified polysiloxane accounts for Mg(OH) 2 weight percent.

[0076] In the structural unit of the graft-modified polysiloxane used in label 15, R is a methoxyl group, and W is a phenyl group, which is octamethylcyclotetrasiloxane plus sulfuric acid ring-opening and phenyltrimethoxysilane equilibrium aggregated to obtain.

[0077] The structural unit R of the graft-modified polysiloxane adopted by the label 16 is an aminopropyl group, and W is a methyl group; Obtained by equilibrium polymerization of silanes.

[0078] The structural unit R of the graft-modified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com