Preparation method and application of metal modified MCM-41 molecular screen

A MCM-41, metal modification technology, applied in the direction of crystalline aluminosilicate zeolite, can solve the problems of high heat release, high thermal weight loss, low thermal degradation to carbon, etc., to achieve good thermal degradation performance, smoke emission Small, the effect of improving the flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

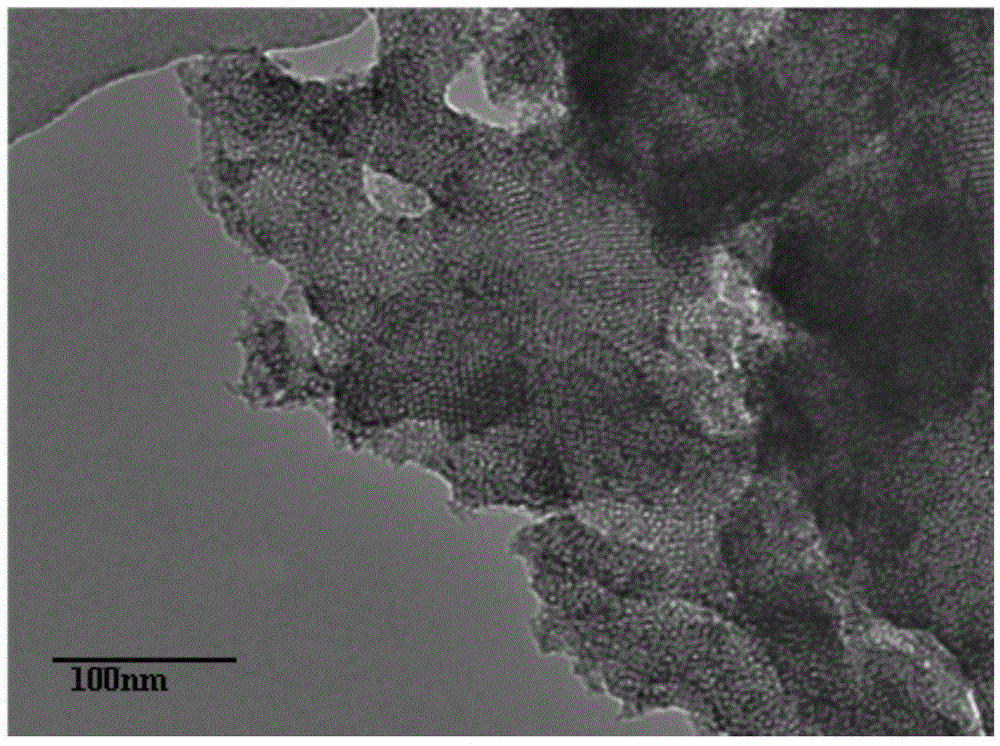

[0019] Specific embodiment one: present embodiment a kind of preparation method of metal modified MCM-41 molecular sieve, this method is realized according to the following steps:

[0020] 1. Dissolve 0.56g-1.1g cetyltrimethylammonium bromide in 18mL-40mL deionized water, add 5mL ammonia water, 0.4g-0.7g tartaric acid and 0.4g-0.9g metal modifier in turn, and stir After 0.5h~1.5h, add 3mL~5mL of silicon source material, adjust the pH value to 8~12; continue to stir for 6h~8h, then adjust the temperature of the reactor to 90℃~120℃ for 24 hours;

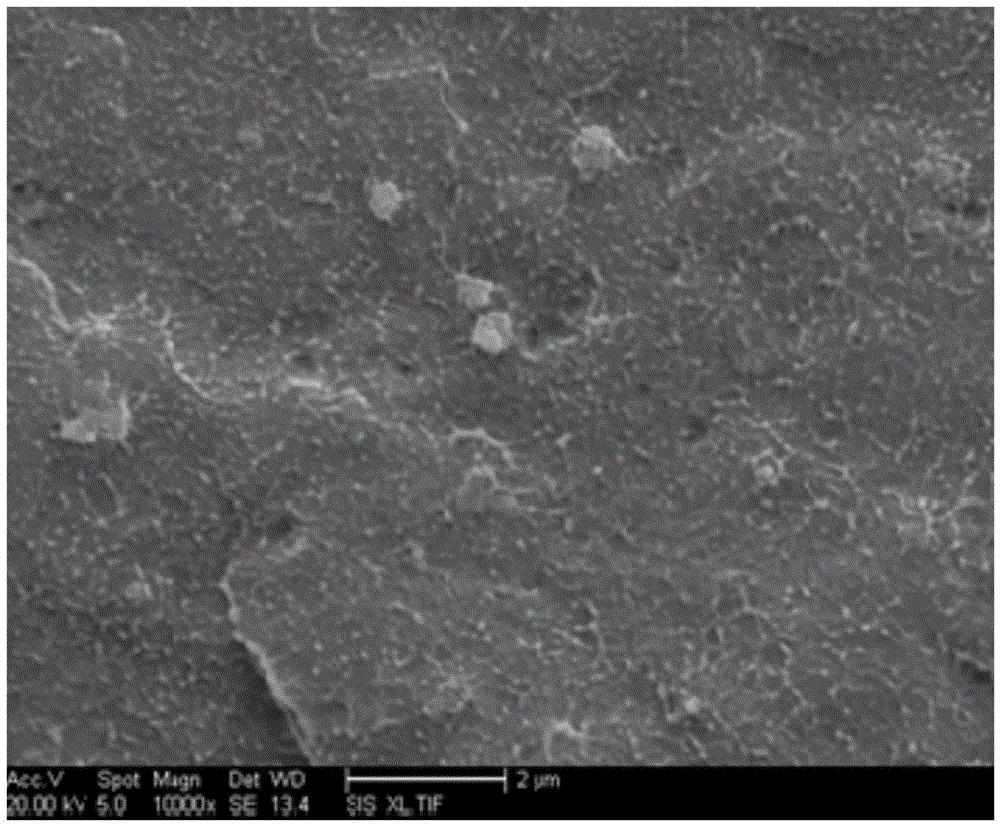

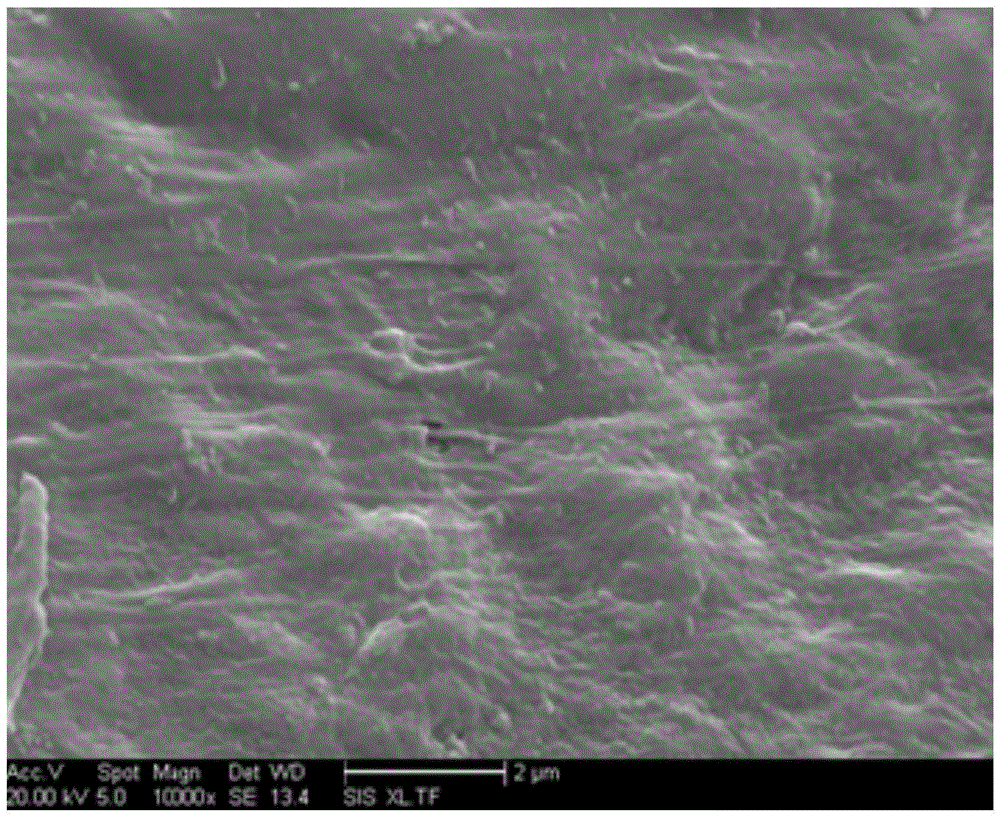

[0021] 2. Take the reactants out of the reaction kettle, wash them with deionized water, filter them, put them in an oven, and dry them at 80°C for 5 to 8 hours, then place the dried reactants in a muffle furnace to Raise the temperature to 500°C-600°C at a heating rate of 3°C / min, and keep it warm for 3-8 hours. At this time, the template agent hexadecyltrimethylammonium bromide is removed, and the metal-modified MCM-41 molecular siev...

specific Embodiment approach 2

[0025] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the mass concentration of ammonia water described in step one is 20%. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the reagent used to adjust the pH value in step 1 is sodium hydroxide. Other steps and parameters are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com