A wear-resistant and flame-retardant carbon fiber reinforced polyphenylene sulfide composition and its preparation method

A technology of polyphenylene sulfide and composition, which is applied in the field of carbon fiber reinforced polyphenylene sulfide composition and its preparation, and can solve problems affecting the performance of carbon fiber reinforced polyphenylene sulfide composite materials, low content of glass beads, and affecting carbon fibers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

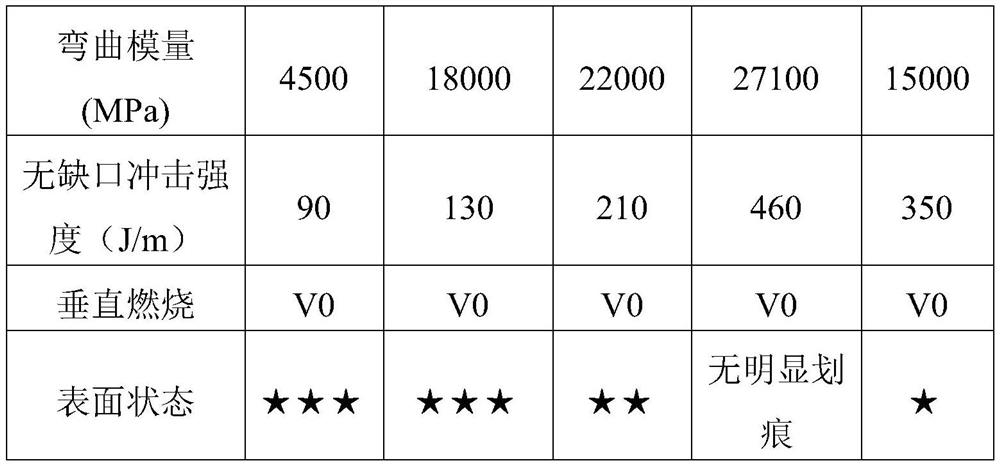

Embodiment 1

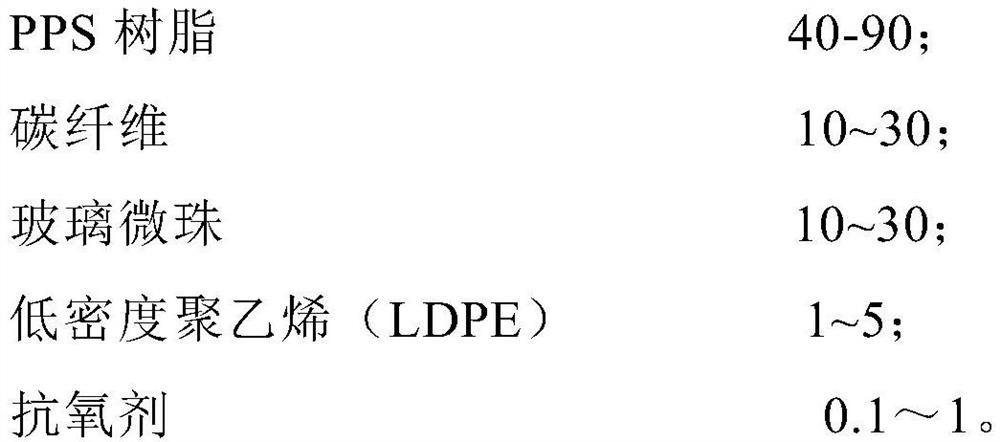

[0032] A wear-resistant and flame-retardant carbon fiber reinforced polyphenylene sulfide composition and a preparation method thereof, the method comprising the following steps:

[0033] (1) Weigh each component by weight: PPS1: 45, carbon fiber: 30, glass beads: 30, LDPE: 5, antioxidant, 0.5; among them, PPS1 is MI (316 ° C * 5kg) is 300g / 10min of PPS; carbon fiber is Toray’s T700, the particle size of the glass beads is 2um, the weight average molecular weight of LDPE is 3000, and the antioxidants are antioxidant 1010 and antioxidant 168 produced by CIBA.

[0034] (2) After mixing PPS1 and antioxidant, feed it from the main feed port of the extruder, and feed carbon fiber and glass microspheres from the side feed port separately, and melt and extrude at 280-310 °C, screw extruder The rotational speed is 500rpm, the pressure is 2MPa, and the product is obtained through melt extrusion and granulation.

Embodiment 2

[0036] A wear-resistant and flame-retardant carbon fiber reinforced polyphenylene sulfide composition and a preparation method thereof, the method comprising the following steps:

[0037] (1) Weigh each component by weight: PPS1: 55, carbon fiber: 30, glass microspheres: 10, LDPE: 5, antioxidant 0.3; among them, PPS1 is MI (316 ° C * 5kg) is 300g / 10min The carbon fiber is Toray's T700, the particle size of the glass beads is 2um, the weight average molecular weight of LDPE is 3000, and the antioxidant is antioxidant 1010 and antioxidant 168 produced by CIBA.

[0038] (2) After mixing PPS1 and antioxidant, feed it from the main feeding port of the extruder, feed carbon fiber and glass microspheres from the side feeding port, melt and extrude at 280-310 °C, and screw extruder The rotational speed is 500rpm, the pressure is 2MPa, and the product is obtained through melt extrusion and granulation.

Embodiment 3

[0040] A wear-resistant and flame-retardant carbon fiber reinforced polyphenylene sulfide composition and a preparation method thereof, the method comprising the following steps:

[0041](1) Weigh each component by weight: PPS1: 47, carbon fiber: 20, glass beads: 20, LDPE: 3, antioxidant 0.1-1; among them, PPS1 is MI (316°C*5kg) is 300g The PPS of / 10min; carbon fiber is T700 of Toray, the particle diameter of glass bead is 2um, the weight-average molecular weight of LDPE is 3000, and antioxidant is the antioxidant 1010, antioxidant 168 that CIBA company produces.

[0042] (2) After mixing PPS1 and antioxidant, feed it from the main feed port of the extruder, and feed carbon fiber and glass microspheres from the side feed port separately, and melt and extrude at 280-310 °C, screw extruder The rotational speed is 500rpm, the pressure is 2MPa, and the product is obtained through melt extrusion and granulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com