Aqueous pencil lacquer and production technology thereof

A production process and technology for pencils, applied in the direction of biocide-containing paints, antifouling/underwater coatings, coatings, etc., can solve the problems of unfavorable physical and mental health of users, physical and mental damage of users, poor practical application effect, etc. Achieve the effect of protecting physical and mental health, less harmful substances, and less odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

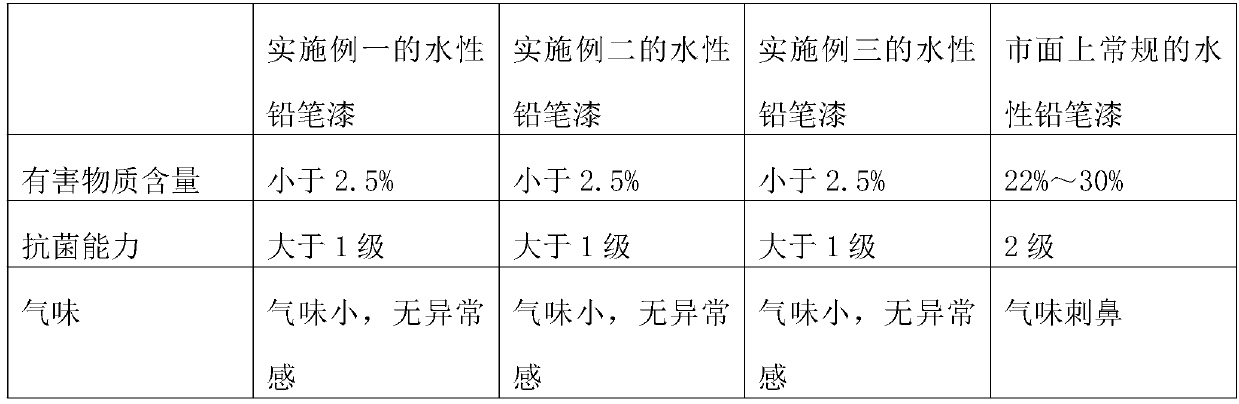

Examples

Embodiment 1

[0018] This water-based pencil paint is made of the following raw material proportions by weight: 100 parts of water-based resin, 5 parts of film-forming aid, 0.5 part of defoamer, 3 parts of dispersant, 5 parts of thickener, heat stabilizer 2 parts of agent, 1 part of wetting agent, 1 part of surfactant, 0.5 part of green tea powder, 0.2 part of ginkgo leaf powder, 200 parts of water.

[0019] The production technology of above-mentioned water-based pencil paint, comprises the steps:

[0020] The first step is to weigh the raw materials. Weigh all the raw materials according to the parts by weight, then take the mixing container, add water, water-based resin, and film-forming aids to the mixer, and then add defoamers, dispersants, thickeners agent, heat stabilizer, wetting agent, surfactant, stir evenly, then add green tea powder, ginkgo leaf powder, stir again, obtain the raw material mixture for the first time;

[0021] In the second step, stirring, the first raw material ...

Embodiment 2

[0027] This water-based pencil paint is made of the following raw material proportions by weight: 120 parts of water-based resin, 8 parts of film-forming aid, 0.6 part of defoamer, 5 parts of dispersant, 7 parts of thickener, heat stabilizer 3 parts of agent, 2 parts of wetting agent, 2 parts of surfactant, 0.6 part of green tea powder, 0.3 part of ginkgo leaf powder, 220 parts of water.

[0028] The production technology of above-mentioned water-based pencil paint, comprises the steps:

[0029] The first step is to weigh the raw materials. Weigh all the raw materials according to the parts by weight, then take the mixing container, add water, water-based resin, and film-forming aids to the mixer, and then add defoamers, dispersants, thickeners agent, heat stabilizer, wetting agent, surfactant, stir evenly, then add green tea powder, ginkgo leaf powder, stir again, obtain the raw material mixture for the first time;

[0030] In the second step, stirring, the first raw materia...

Embodiment 3

[0036] This water-based pencil paint is made of the following raw material proportions by weight: 150 parts of water-based resin, 10 parts of film-forming aid, 0.8 part of defoamer, 6 parts of dispersant, 8 parts of thickener, heat stabilizer 4 parts of agent, 3 parts of wetting agent, 3 parts of surfactant, 0.8 part of green tea powder, 0.4 part of ginkgo leaf powder, 250 parts of water.

[0037] The production technology of above-mentioned water-based pencil paint, comprises the steps:

[0038] The first step is to weigh the raw materials, weigh all the raw materials according to the parts by weight, then take the mixing container, add water, water-based resin, and film-forming aids to the mixer, and then add defoamers, dispersants, thickeners agent, heat stabilizer, wetting agent, surfactant, stir evenly, then add green tea powder, ginkgo leaf powder, stir again, obtain the raw material mixture for the first time;

[0039] In the second step, stirring, the first raw materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com