A multifunctional all-weather automatic dustproof and dust suppression spraying device for wharf berths

A spray device and multi-functional technology are applied in the field of multi-functional all-weather automatic dust-proof and dust-suppression spray devices for dock berths. Maintenance cost saving and other issues, to achieve the effect of solving poor sight line, compact overall structure design, and improving aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

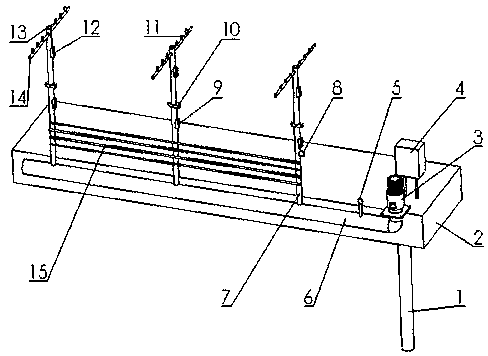

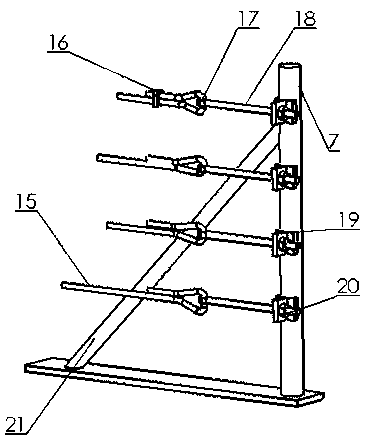

[0022] Embodiment 1: see Figure 1-Figure 5 , a multi-functional all-weather automatic dust-proof and dust-suppressing spraying device for a dock berth. Super long-distance nozzle 14, booster pump and PLC control components, refer to Figure 1, the wharf berth 2 has a total length of 300 meters along the line, and the horizontal direction of the berth platform is embedded with a main outlet pipe 6 with a diameter of 200 mm. The main outlet pipe 6 is vertically equipped with branch water pipes 7 with a height of 6.2 m and a diameter of 65 mm at intervals of 10 m. , the head of the main outlet pipe 6 is equipped with a booster pump 3, and the booster pump 3 is connected to the water inlet pipe 1 and the main outlet pipe 6; the water distribution pipe 11 is arranged symmetrically in the vertical direction along the berth at the top of each branch water pipe 5, and the upper surface of the water distribution pipe 11 is uniform Six 360° water mist nozzles 13 are installed, and the...

Embodiment 2

[0023] Example 2: see Figure 1-Figure 3 As an improvement of the present invention, dust sensors are respectively installed at the heights of 2m and 6m of the branch water pipes 7, wherein the bottom of the branch water pipes is provided with a low-level dust sensor 9, and the upper part of the branch water pipes is provided with a high-level dust sensor 12. The high-level dust sensor 12 mainly collects dust particles floating at high altitude caused by throwing when the grab bucket of the portal crane grabs materials; the low-level dust sensor 9 mainly collects the dust caused by the operation of heavy trucks in the working area.

Embodiment 3

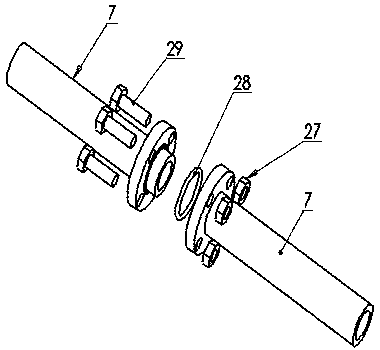

[0024] Embodiment 3: see Figure 1-Figure 4 , as an improvement of the present invention, a three-way pipeline 8 is installed at a height of 1.5m on the branch water pipe 5, which is mainly connected to the water inlet, water outlet and auxiliary water outlet, and the water inlet and water outlet of the three-way pipeline are equipped with There are ball valves 23,24. When the sprinkler system is in normal operation, the water inlet of the branch water pipe 7 is connected to the water outlet, and the auxiliary water outlet is closed; After the fire hose is installed on the head of the auxiliary water outlet, water can be sprayed manually. In addition, another purpose of the auxiliary water outlet is that when the operation of the berth platform is completed and the manual cleaning is completed, there will still be some accumulated material on the surface of the berth. At this time, use the auxiliary water outlet The berth platform can be effectively cleaned by cooperating wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com