Lithium ion battery bubble defect detection method based on ultrasonic detection technology

A technology for lithium-ion batteries and ultrasonic testing, which is applied in processing detection response signals, analyzing solids using sound waves/ultrasonic waves/infrasonic waves, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc. It can solve problems such as poor signal-to-noise ratio, weak signals, etc. problem, to achieve the effect of improving the peak of the main lobe, improving the signal-to-noise ratio, and suppressing noise information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

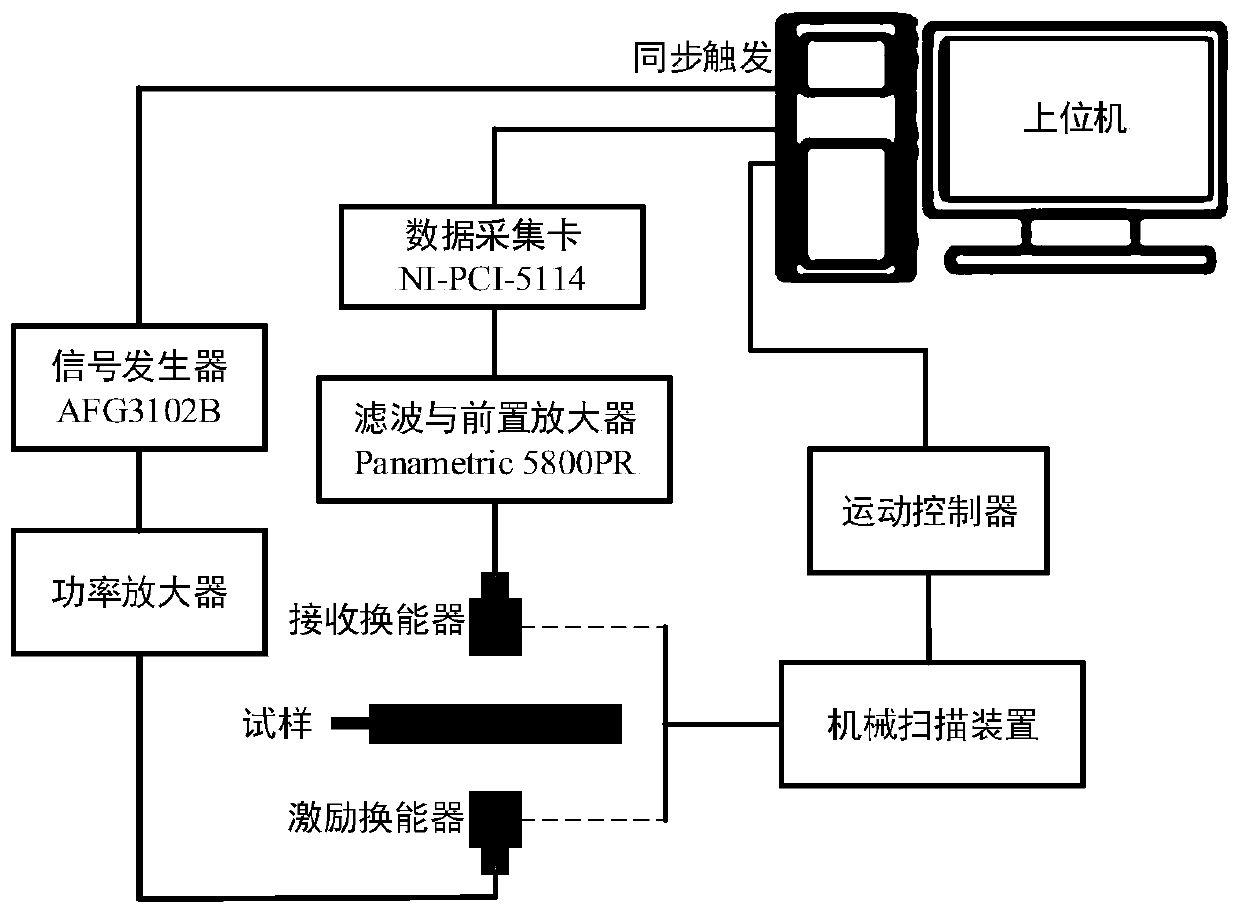

[0035] In order to make the purpose, solution and advantages of the present invention more clearly reflected, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

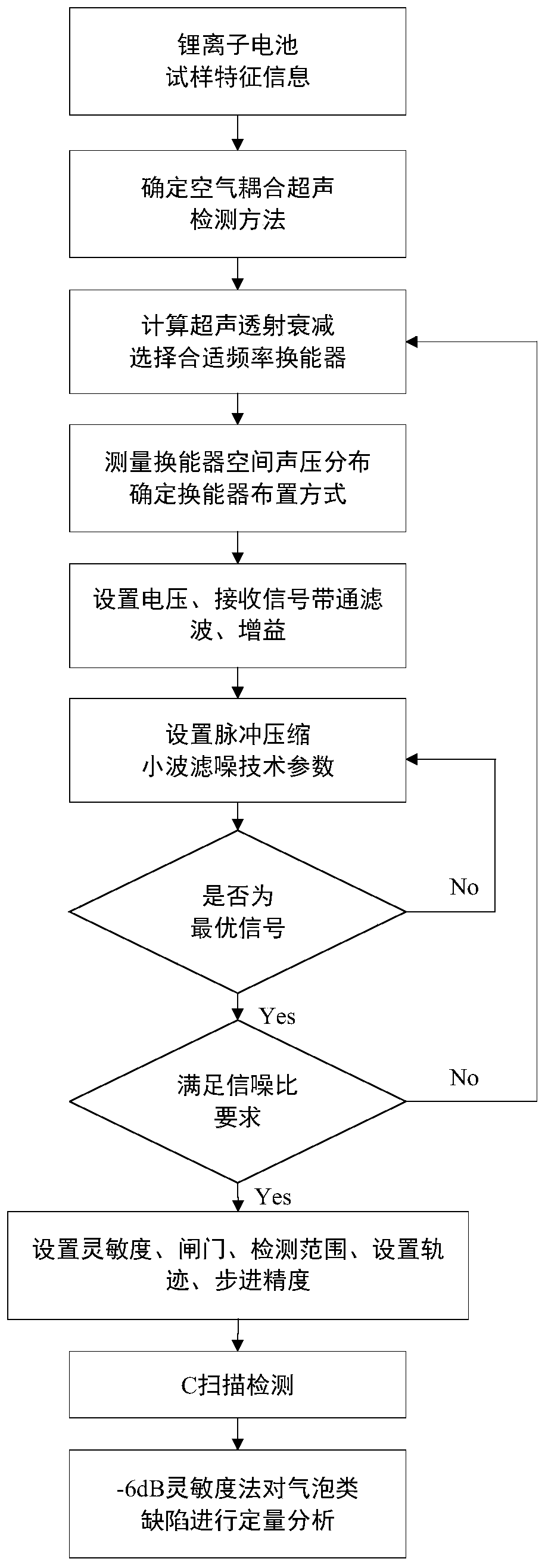

[0036] A method for detecting bubble defects in lithium-ion batteries based on ultrasonic detection technology provided by the present invention, such as figure 2 As shown, it specifically includes the following steps:

[0037] Step 1. According to the characteristics of the multi-pole sheet and the laminated structure of the diaphragm inside the lithium-ion battery, the air-coupled ultrasonic vertical penetration method is selected as the specified detection method of the present invention;

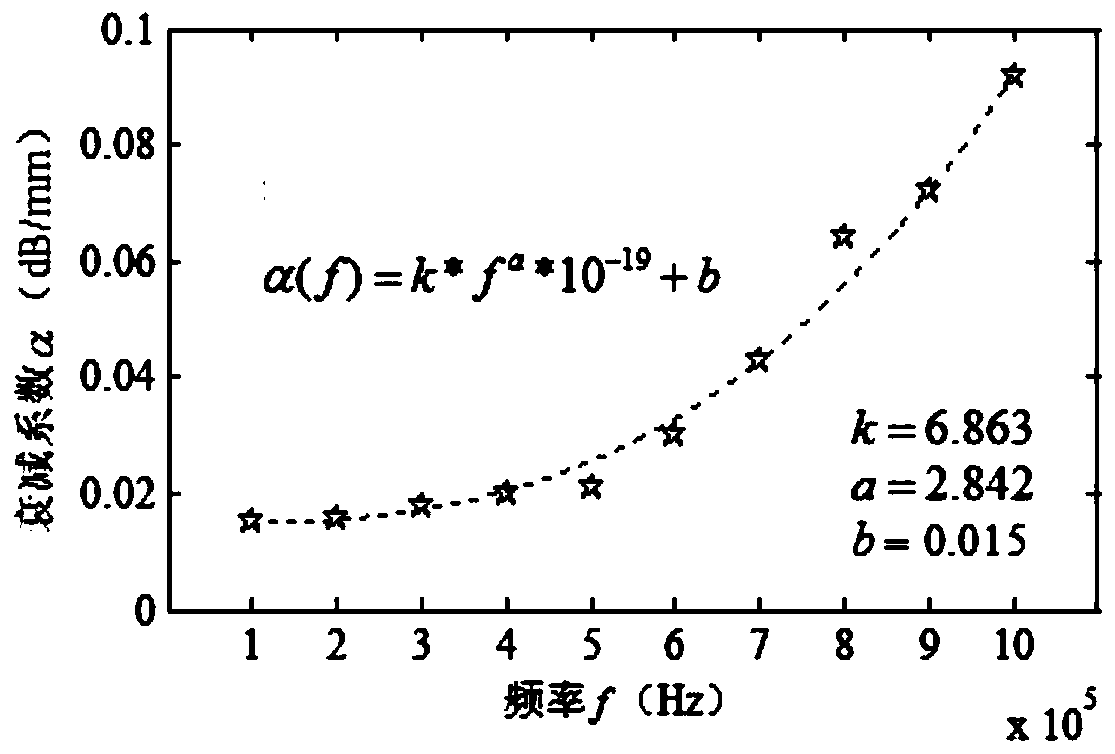

[0038] Step 2: Calculate the attenuation of ultrasonic signals of different frequencies in the air medium, and select a suitable air-coupled ultrasonic transducer. According to the relationship between the sound wave attenuation coefficient and the fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Amplitude | aaaaa | aaaaa |

| Snr | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com