Thermal-mechanical coupling model-based workpiece surface residual stress control and adjustment method

A technology of workpiece surface and residual stress, applied in the field of machining, can solve the problems of inability to control and optimize residual stress, many experimental equipment, and complex experimental conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

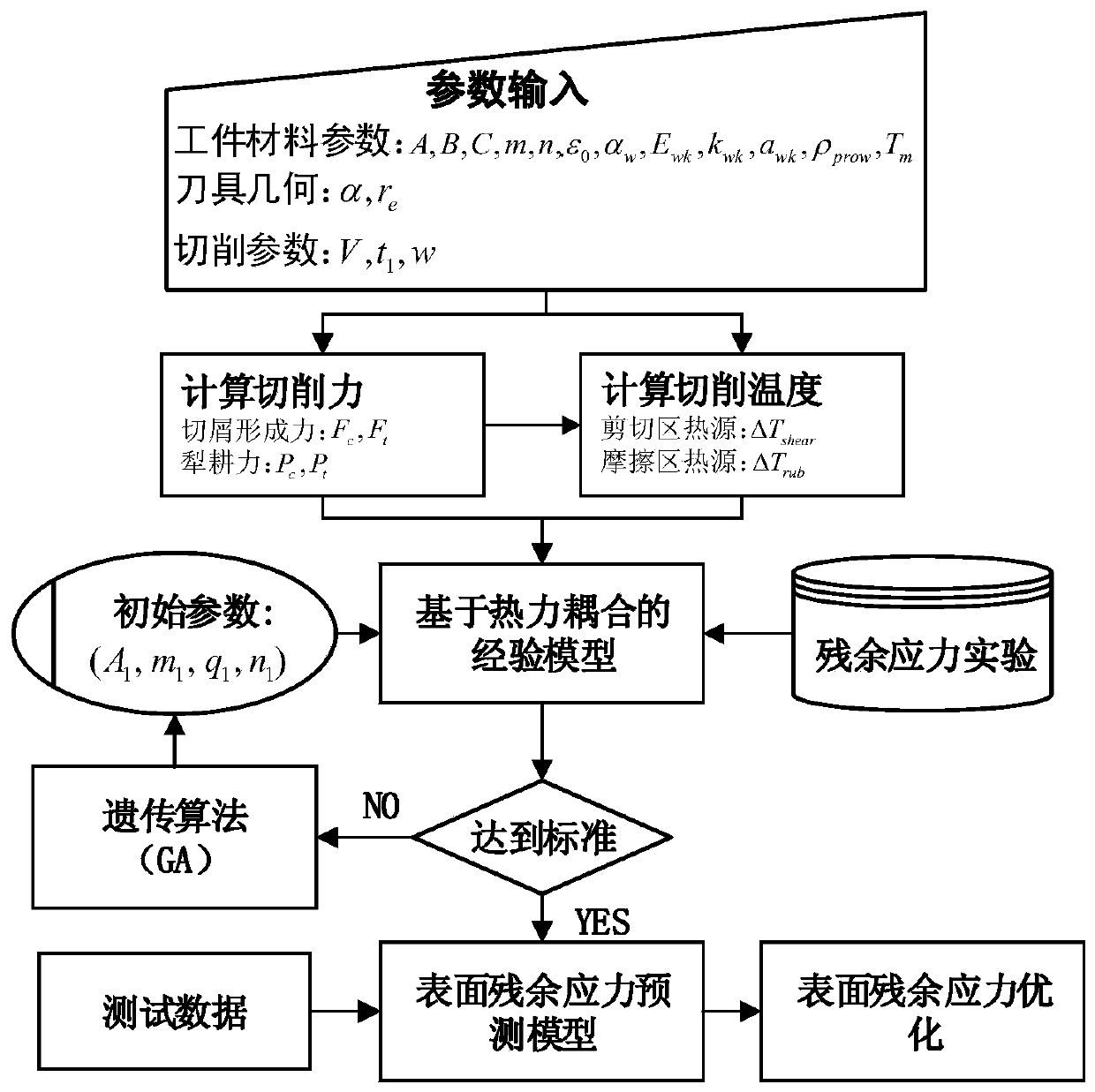

[0112] Example 1. A method for controlling residual stress on workpiece surface based on thermal-mechanical coupling model, such as figure 1 shown, follow the steps below:

[0113] a. Carry out cutting experiments, and measure the corresponding residual stress σ on the surface of the workpiece under the conditions of each set of cutting parameters i ; The cutting parameters include cutting depth a p , cutting speed V and feed f;

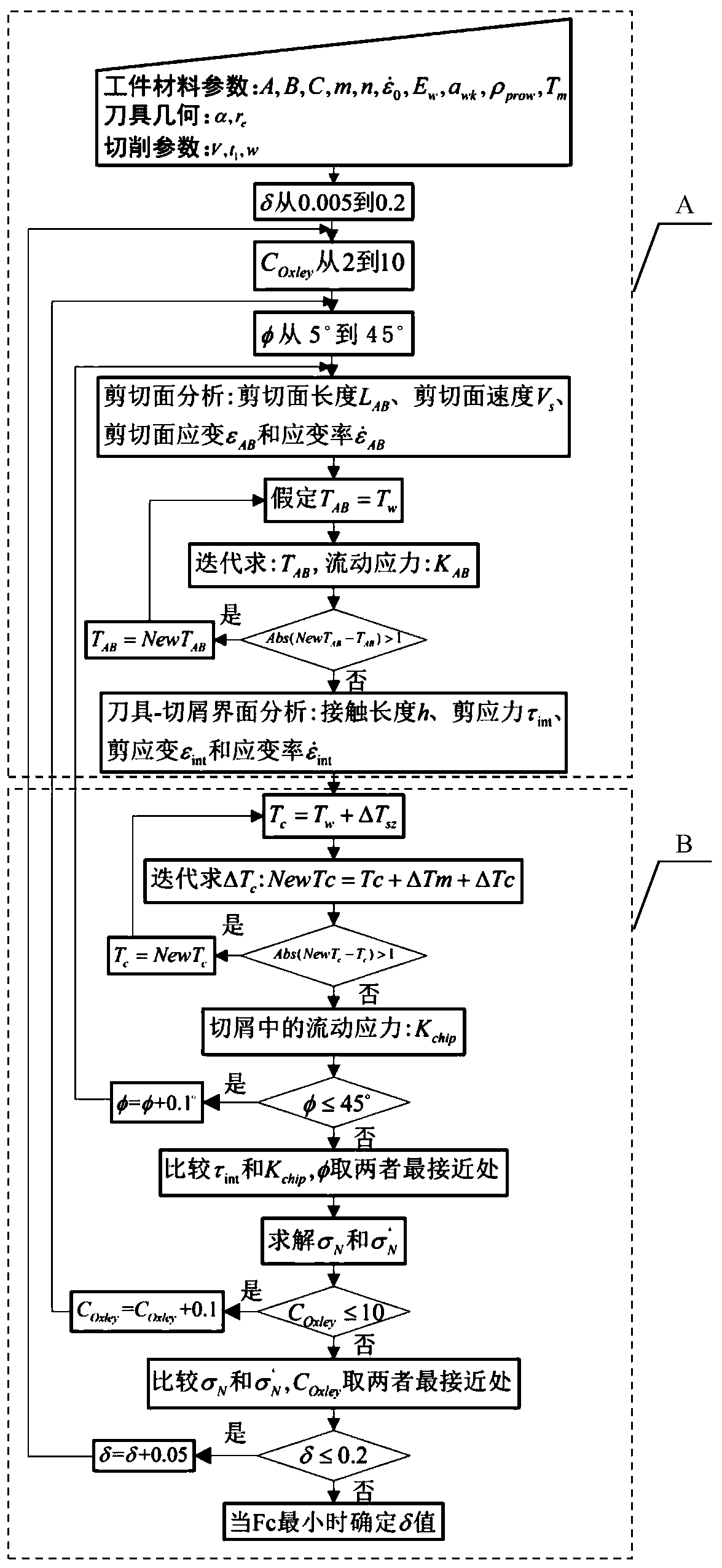

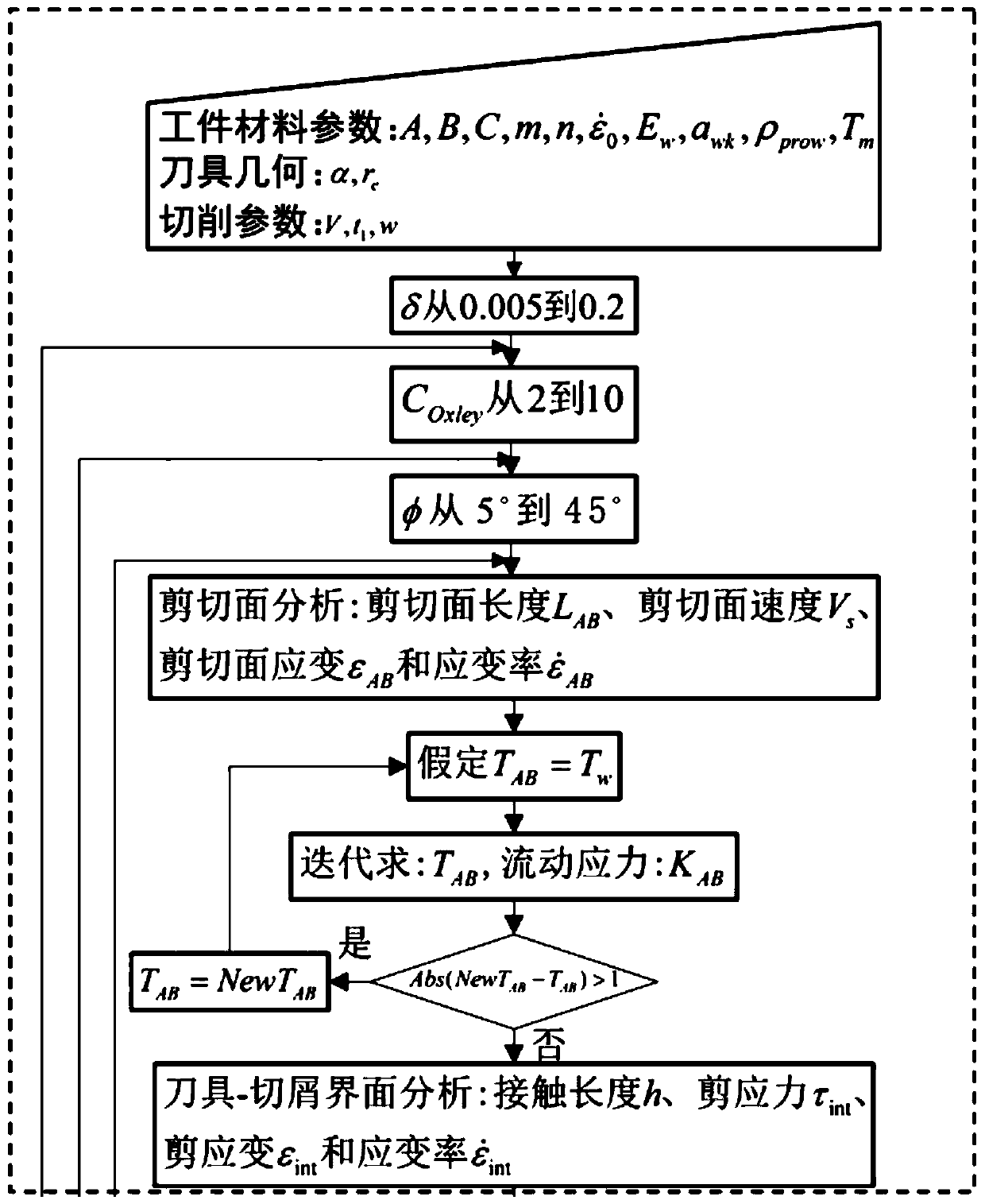

[0114] b. Construct a right-angle cutting force prediction model based on the Oxley prediction model and J-C constitutive model; through this step, a wider application range is established, which does not depend on cutting experiments, and considers the change of material flow stress with strain, strain rate and temperature Analytical prediction model of cutting force.

[0115] c. Based on the thermal stress formed by the temperature superposition of the shear zone and the plowing zone, a workpiece temperature prediction model is constructed;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com