A kind of method for preparing α-bismuth niobate photocatalyst

A photocatalyst, bismuth niobate technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as α-bismuth niobate that have not yet been seen, Achieve the effect of high catalytic degradation efficiency, wide adaptability and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

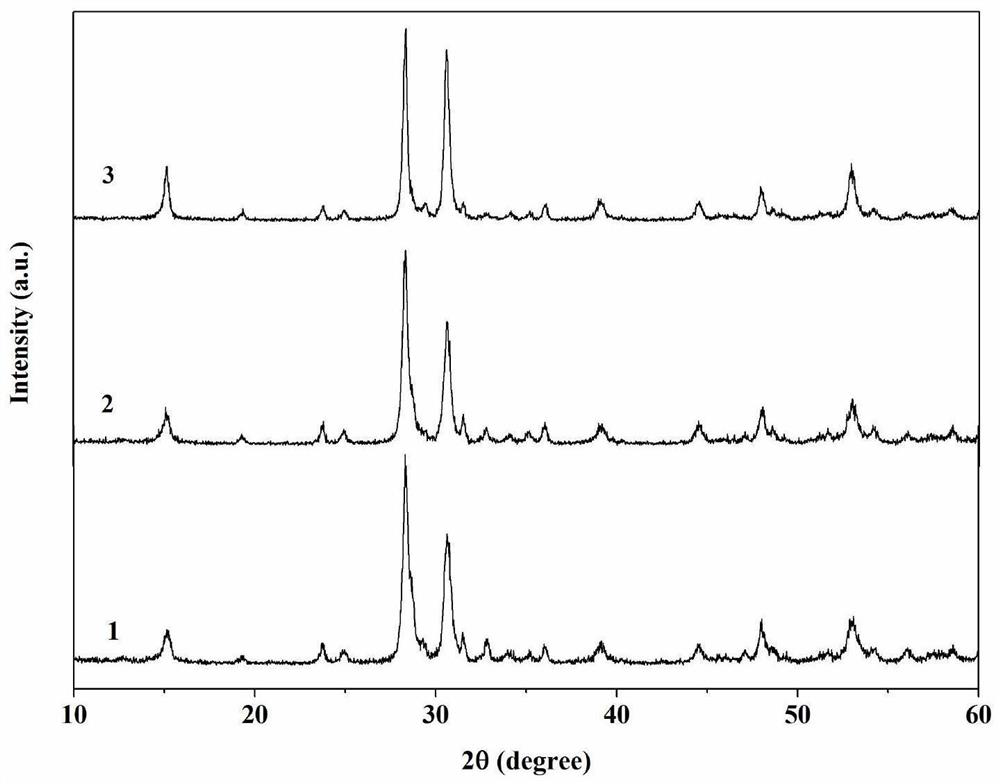

Embodiment 1

[0034] Step 1, preparation reaction solution, its specific steps are:

[0035] a, take by weighing niobium pentachloride (NbCl) that quality is 0.5403g 5 ), and bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O), the mol ratio of the two is 1:1;

[0036] b. Pour the niobium pentachloride weighed in step a into 10 mL of absolute ethanol, and stir magnetically for 20 minutes to fully dissolve the niobium pentachloride. The resulting solution is marked as solution A; Pour bismuth into 10mL of absolute ethanol, and stir magnetically for 20 minutes to fully dissolve bismuth nitrate pentahydrate, and the resulting solution is marked as B solution;

[0037] c. Slowly add the A solution obtained in step b into the B solution. During the dropwise addition, the solution gradually becomes clear from turbidity. Stir magnetically for 20 minutes to make a mixed solution; adjust and mix with 25% concentrated ammonia water The pH value of the solution was 8, and magnetically stirred for ...

Embodiment 2

[0046] Step 1, preparation reaction solution, its specific steps are:

[0047] a, take by weighing niobium pentachloride (NbCl) that quality is 0.5404g 5 ), and bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O), the mol ratio of the two is 1:1;

[0048] b. Pour the niobium pentachloride weighed in step a into 20 mL of absolute ethanol, and stir for 30 minutes with a magnetic stirrer to fully dissolve the niobium pentachloride, and the resulting solution is marked as solution A; in addition, the niobium pentachloride weighed in step a Pour bismuth nitrate pentahydrate into 20mL of absolute ethanol, and stir for 30min with a magnetic stirrer to fully dissolve bismuth nitrate pentahydrate, and mark the obtained solution as B solution;

[0049] c. Slowly add the A solution obtained in step b into the B solution. During the dropwise addition, the solution gradually becomes clear from turbidity. Stir magnetically for 30 minutes to make a mixed solution; adjust and mix with 26% co...

Embodiment 3

[0058] Step 1, preparation reaction solution, its specific steps are:

[0059] a, take by weighing niobium pentachloride (NbCl) that quality is 0.5406g 5 ), and bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O), the mol ratio of the two is 1:1;

[0060] b. Pour the niobium pentachloride weighed in step a into 30 mL of absolute ethanol, and stir for 40 minutes with a magnetic stirrer to fully dissolve the niobium pentachloride, and the resulting solution is marked as solution A; in addition, the niobium pentachloride weighed in step a Pour bismuth nitrate pentahydrate into 30 mL of absolute ethanol, and stir for 40 minutes with a magnetic stirrer to fully dissolve bismuth nitrate pentahydrate, and mark the obtained solution as B solution;

[0061] c. Slowly add the A solution obtained in step b into the B solution. During the dropwise addition, the solution gradually becomes clear from turbidity. Stir magnetically for 40 minutes to make a mixed solution; adjust and mix wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com