Carbon nanotube dispersing agent for dispersing carbon nanotubes and preparation method and application of carbon nanotube dispersing agent

A carbon nanotube and dispersant technology, applied in the field of carbon nanotube dispersant and its preparation, can solve the problems of destroying the structure of carbon nanotubes, reducing electrical and thermal properties, and easily re-entanglement and agglomeration of carbon tubes. Excellent compatibility, the effect of important commercial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

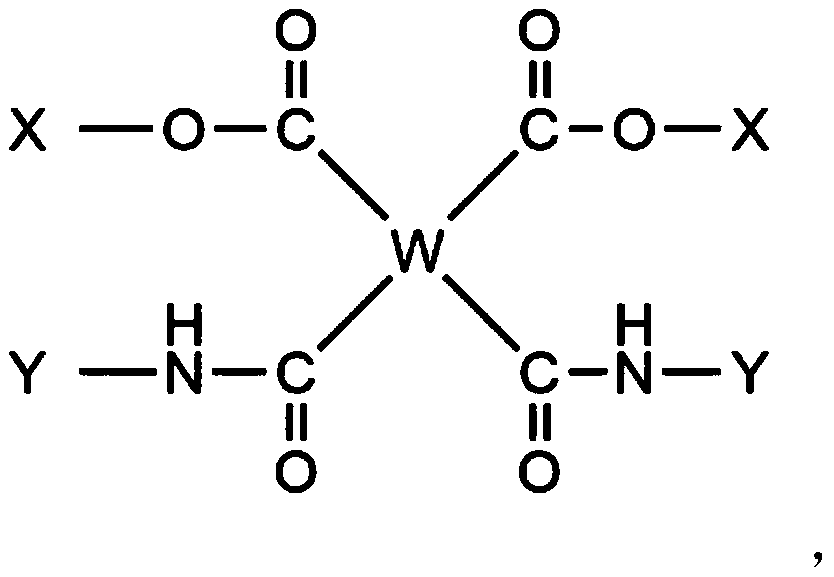

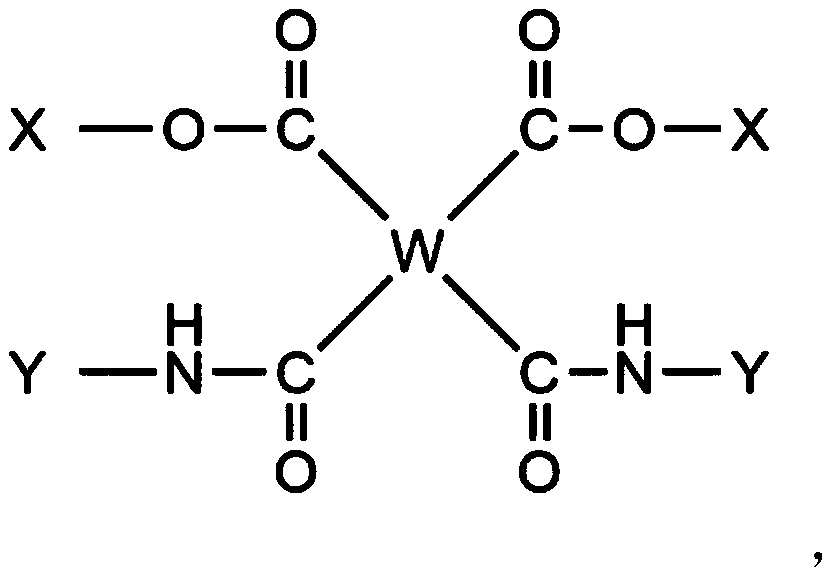

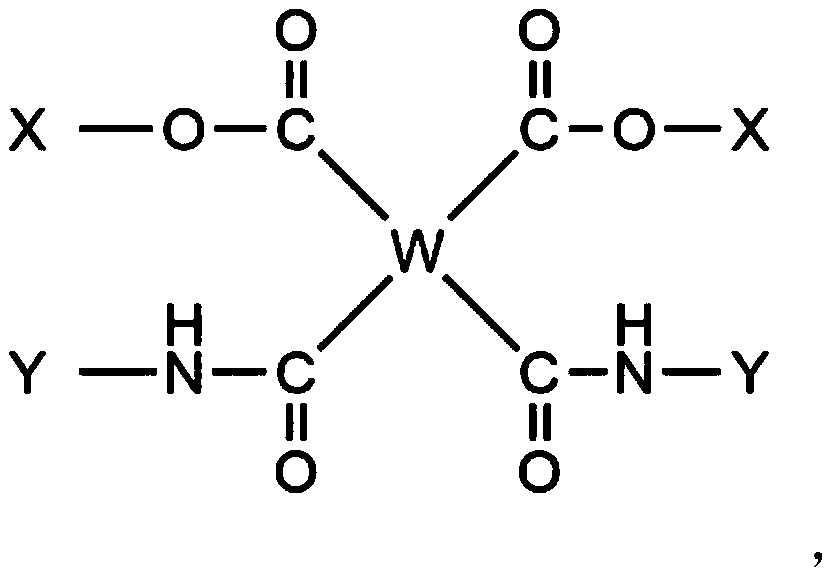

Method used

Image

Examples

Embodiment 1

[0051] Put 13 parts of 4,4'-oxydiphthalic anhydride and 120 parts of NMP into a 500ml flask equipped with a mechanical stirring and condensing reflux device, and raise the temperature to 90°C to obtain a mixed solution of NMP;

[0052] Add 15.6 parts of lauryl alcohol, 0.2 parts of p-toluenesulfonic acid and 23 parts of NMP mixed solution dropwise into the reaction bottle, and react for 1 hour after the dropwise addition, until the characteristic peak of acid anhydride on the infrared spectrum FTIR disappears,

[0053] Introduce nitrogen, add 84 parts of polyetheramine L-100 and 1.2g of p-toluenesulfonic acid into the flask, react at 180°C for 7 hours, titrate the amine value of the solution, the reaction conversion rate is >90%, and remove the solvent by distillation under reduced pressure , to obtain the carbon nanotube high-efficiency dispersant 1.

Embodiment 2

[0055] Put 10 parts of 4,4'-oxydiphthalic anhydride and 100 parts of NMP into a 500ml flask equipped with a mechanical stirring and condensing reflux device, and raise the temperature to 90°C to obtain a mixed solution of NMP;

[0056] Add 12 parts of lauryl alcohol, 0.2 parts of p-toluenesulfonic acid and 10 parts of NMP mixed solution dropwise into the reaction flask, and react for 1 hour after the dropwise addition, until the characteristic peak of anhydride on the infrared spectrum FTIR disappears;

[0057] Introduce nitrogen, add 129 parts of polyetheramine L-207 and 1.2 g of p-toluenesulfonic acid into the flask, react at 180°C for 7 hours, titrate the amine value of the solution, the reaction conversion rate is >90%, and remove the solvent by distillation under reduced pressure. The carbon nanotube high-efficiency dispersant 2 was obtained.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap