Control system for multi-pulse width loading equipment based on dual-axis separated Hopkinson tension and compression rods

A technology of loading equipment and control system, which is applied to the control system of material dynamic mechanical property testing experimental equipment, based on the field of biaxial separated multi-pulse width Hopkinson tension and compression rod experimental equipment control system, can solve the problem of reverse current elongation Pulse width, influence of experimental results, difficulty in operation, etc., to achieve the effect of reducing complexity, avoiding adverse effects, and making the discharge process easier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

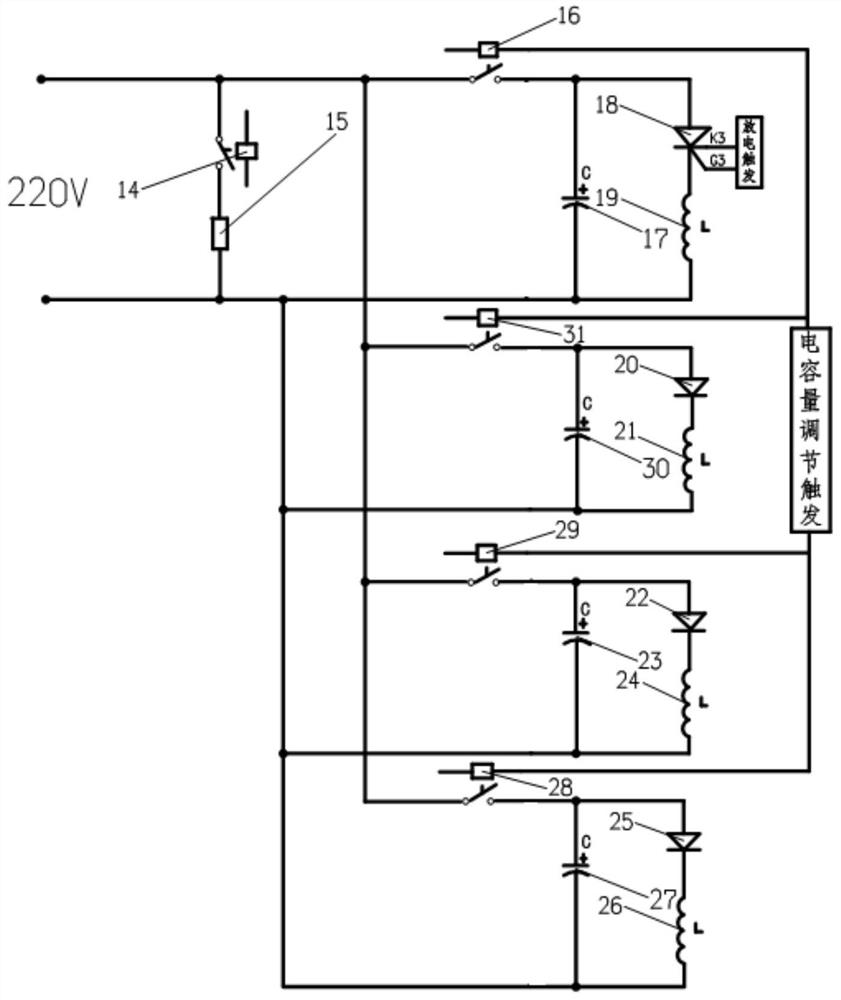

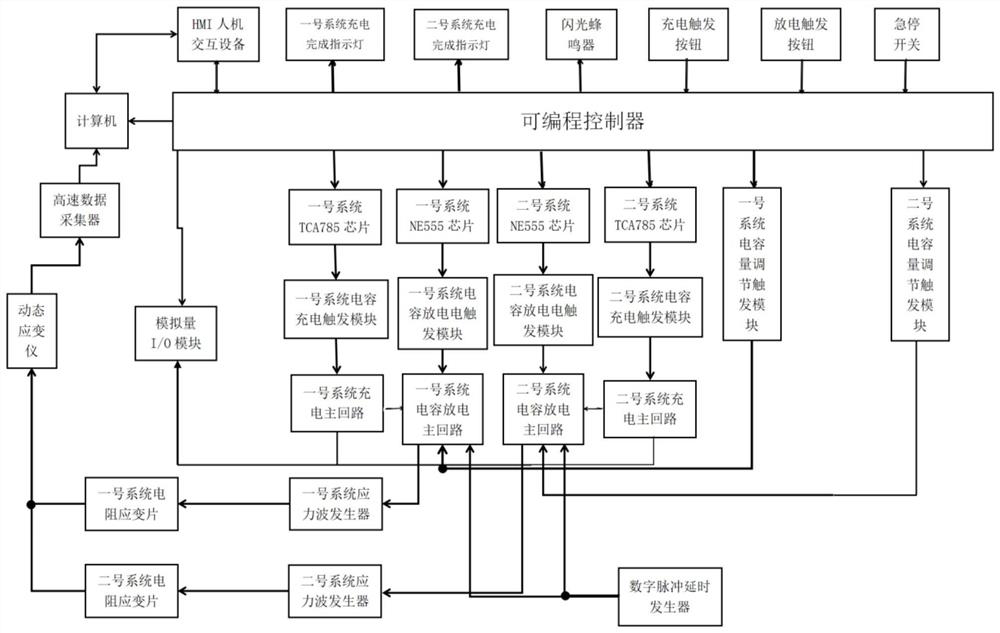

[0024] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0025] The present invention proposes a control system for a dual-axis multi-pulse width Hopkinson pressure bar experimental device based on electromagnetic force loading, the control system includes: HMI human-computer interaction equipment, a programmable controller, and the charging completion indicator of the No. 1 system , No. 2 system charging completion indicator light, flashing buzzer, charging trigger button, discharge trigger button, emergency stop switch, analog I / O module, No. 1 system TCA785 chip, No. 2 system TCA785 chip, No. 1 system NE555 chip , System No. 2 NE555 chip, System No. 1 capacitor charging trigger module, System No. 2 capacitor charging trigger module, System No. 1 capacitor discharge trigger module, System No. 2 capacitor discharge trigger module, System No. 1 charging main circuit, System No. 2 charging The main circuit, the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com