A kind of field emission cathode material, preparation method and application thereof

A field emission cathode and carbon fiber material technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of high preparation temperature and complicated preparation process of field emission cathode materials, and achieve good mechanical properties and chemical stability, simple preparation process, low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The flexible field emission cathode material of the present invention is prepared by reacting carbon fiber and urea solution at 450° C. to 600° C. to generate graphite-like carbon nitride on the surface of the carbon fiber, that is, the flexible field emission cathode material. Specifically, the preparation process includes:

[0038] First, arrange the carbon fibers in a mixture of acetone, ethanol and deionized water at a volume ratio of 1:1:1 for cleaning, and after drying, place them in urea solution for 30-60 minutes of ultrasonication;

[0039] Then, heat the solution to 450°C-600°C for 1-5 hours at a heating rate of 10-15°C / min, and cool naturally;

[0040] Finally, after washing and drying, the carbon fiber material with graphite-like carbon nitride grown on the surface can be obtained, that is, the flexible field emission cathode material.

[0041] Wherein, the urea solution is a saturated solution of urea, so as to avoid the influence of high-temperature pyrol...

Embodiment 1

[0045] Cut a carbon fiber cloth with a size of 1×1cm, put it into a mixture of acetone, ethanol and deionized water with a volume ratio of 1:1:1, and after ultrasonic cleaning, rinse with deionized water and absolute ethanol and dry; 15g Mix urea with 10ml of deionized water to prepare a saturated urea solution; add the cleaned and dried carbon fiber cloth into the saturated urea solution and ultrasonicate for 30 minutes; then transfer the carbon fiber cloth and the saturated urea solution to a 50ml crucible with a lid In the muffle furnace, heat up to 600°C at a rate of 15°C / min, keep it warm for 3 hours and then cool naturally; take out the sample, wash it with absolute ethanol and deionized water, and then dry it to obtain a graphite-like phase carbon nitride flexible field emission cathode material.

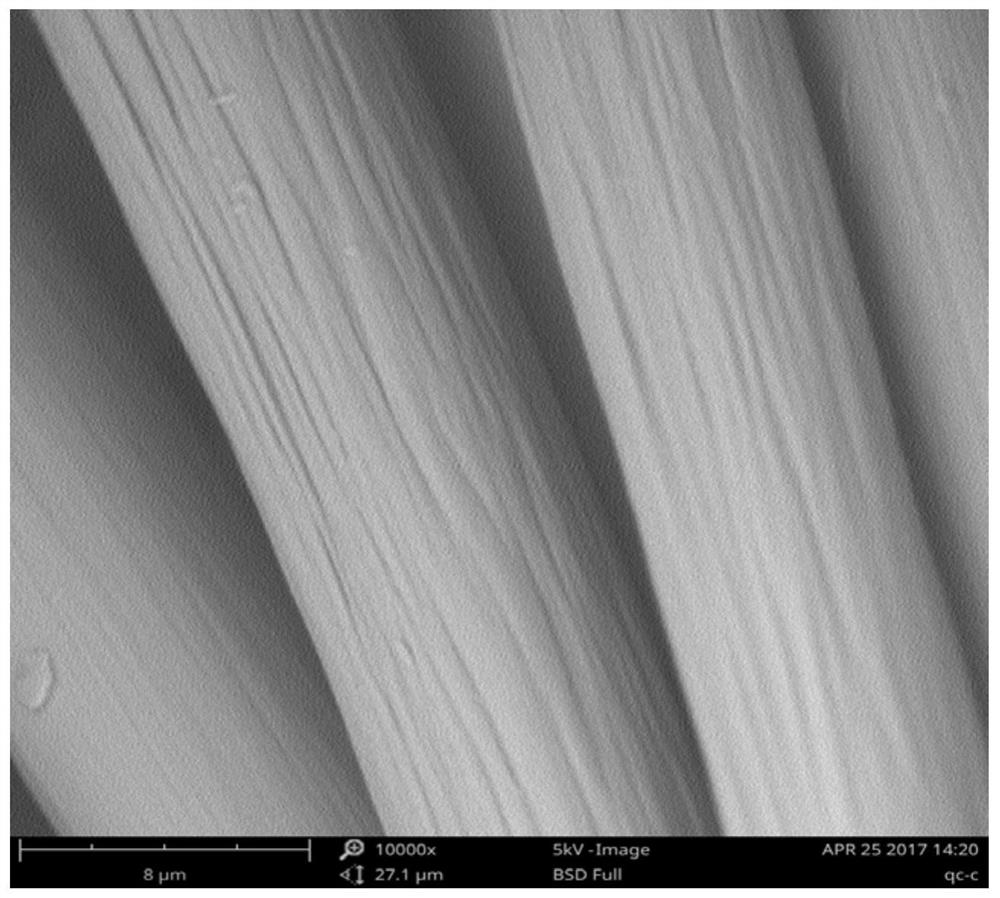

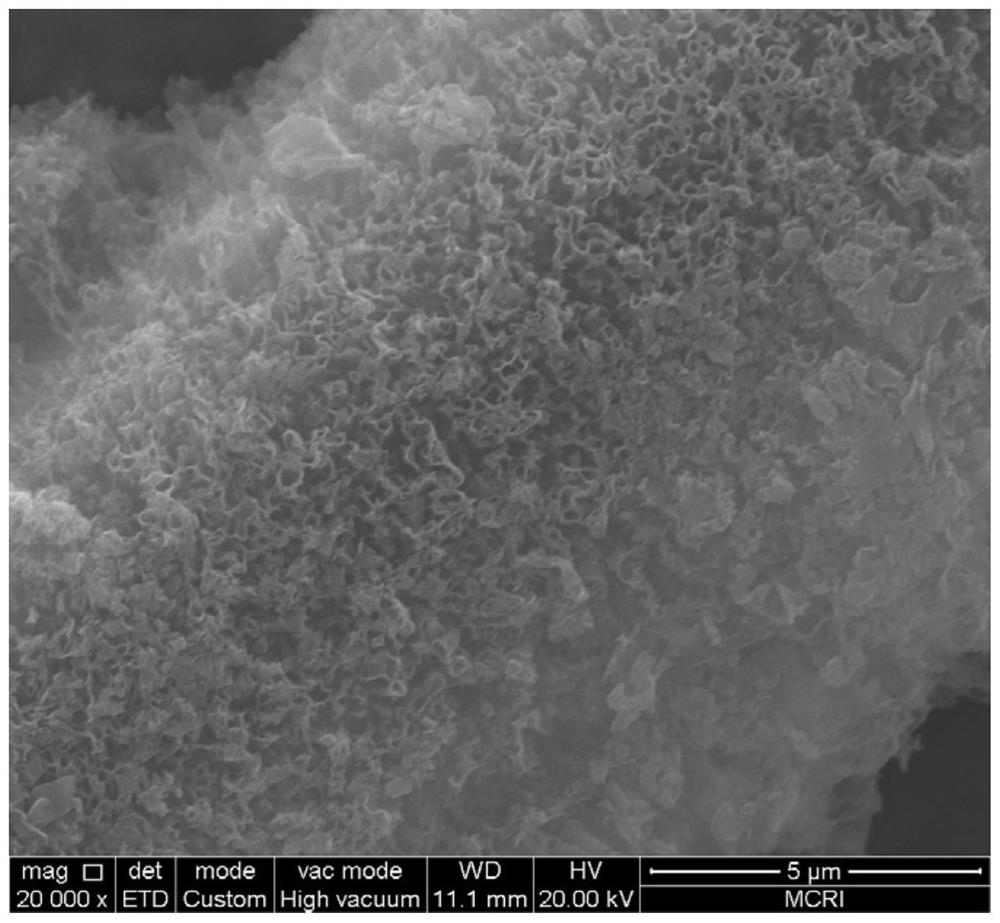

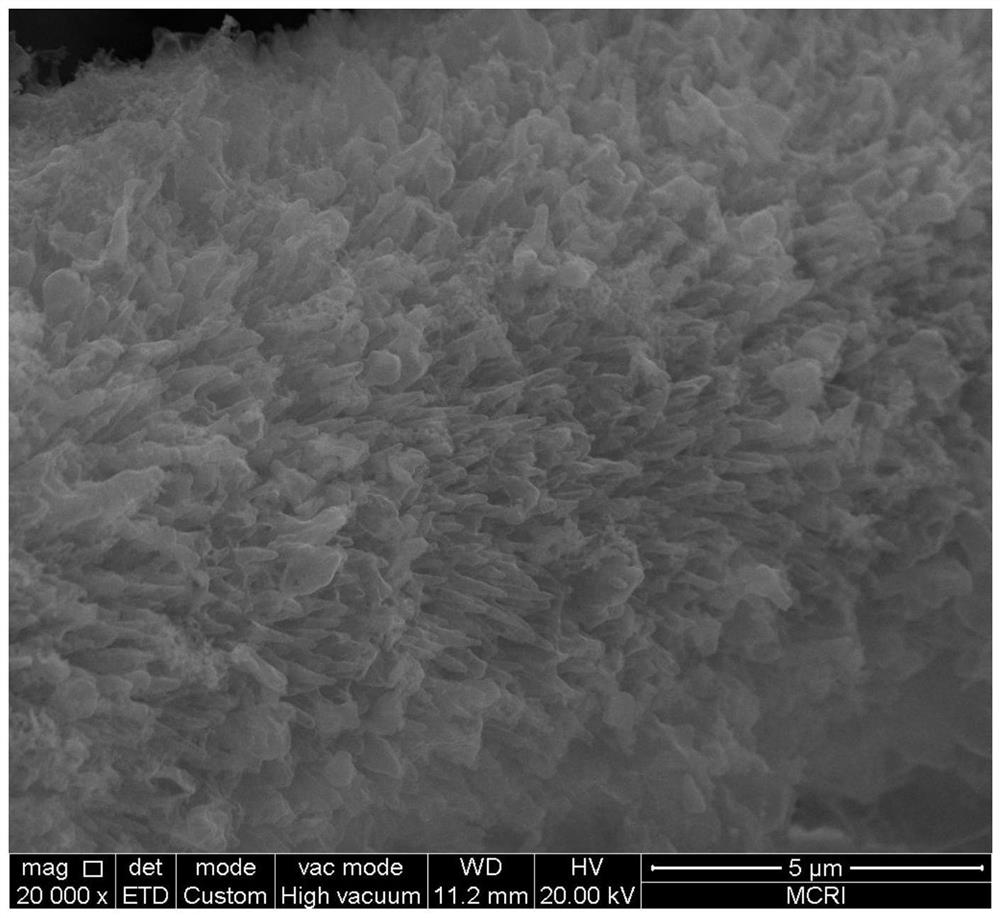

[0046] figure 1 For the SEM image enlarged 10000 times of the carbon fiber cloth substrate used in this embodiment, figure 2 The SEM image of the graphite-like phase carbo...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that the heating temperature in this embodiment is 550° C., and the holding time is 1 h.

[0050] Figure 7 For the field emission J-E characteristic curve of the field emission cathode material prepared in this embodiment, it can be seen that its field emission opening electric field is 0.6V / μm (current density reaches 1μA / cm 2 electric field strength at the time).

[0051] Figure 8 It is the field emission F-N curve of the field emission cathode material obtained in this embodiment. It can be seen that the field emission F-N curve is approximately linear, indicating that the electron emission of this embodiment conforms to the field emission mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com