Preparation process of emblic leafflower fruit enzyme product with mixed bacteria segmented fermentation and prepared enzyme product

A preparation process and staged fermentation technology, applied in the field of enzyme products, can solve the problems of complex equipment process, long fermentation time, and ultrasonic energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] 1. Raw material selection (emblica treatment): select 50 kg of fresh, non-rotten and mildew-free wild small fruit emblica in Puning, Guangdong Province, wash by hand with tap water, and dry the surface moisture naturally in a cool place.

[0062] 2. Whole fruit cutting of emblica: use a clean cutting machine with adjustable blade height to cut emblica on the surface of dry emblica, and adjust the height of the blade so that the cutting depth of the pulp is about 1.5-2mm. Immediately, transfer the emblical on the cut surface to a sterilized, temperature-controlled, agitating, sealable, interlayer stainless steel fermenter (100 L); the free amino acids and free polyphenols of the emblica The contents are 2.60mg / g and 7.80mg / g respectively.

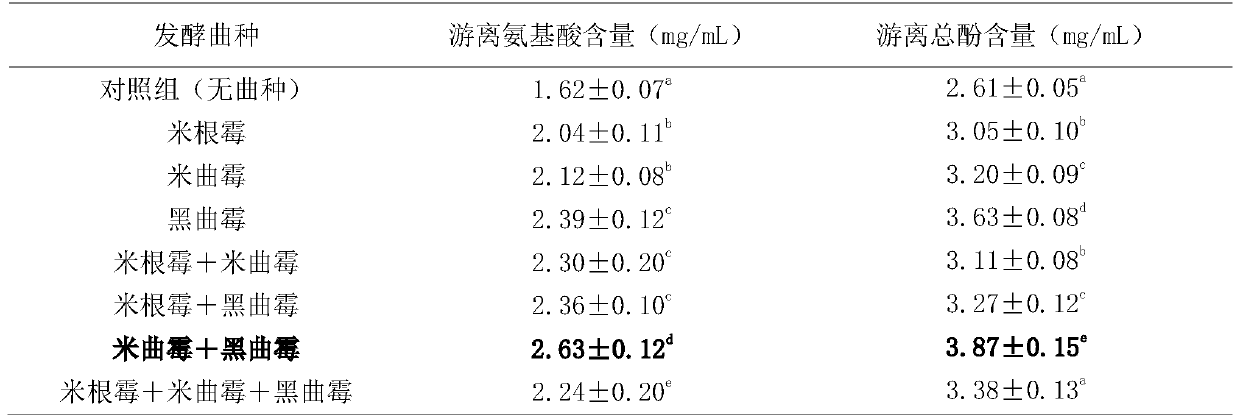

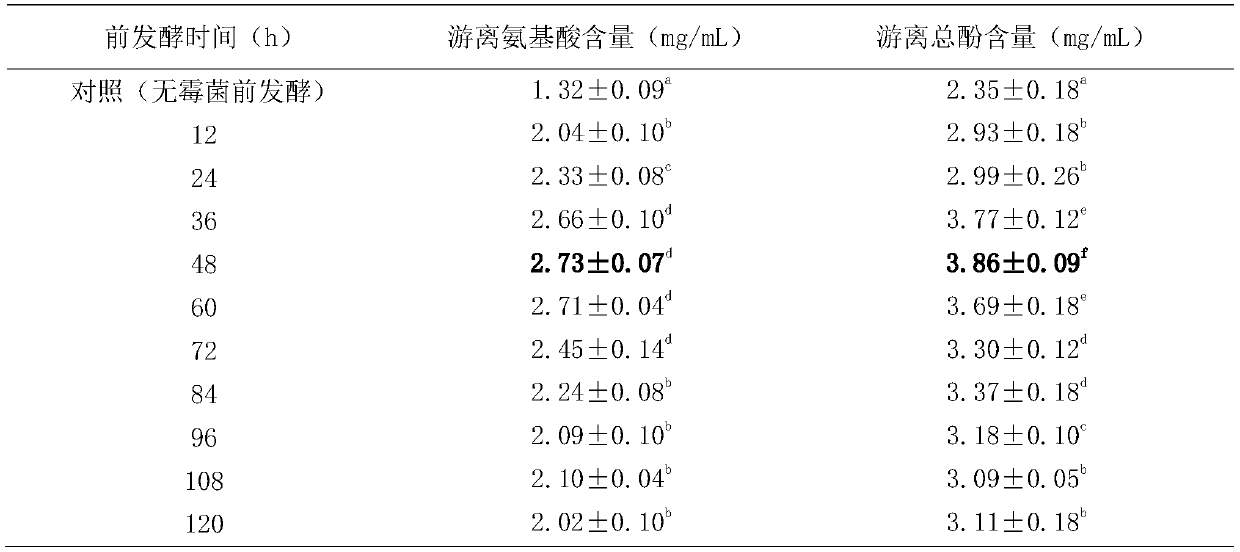

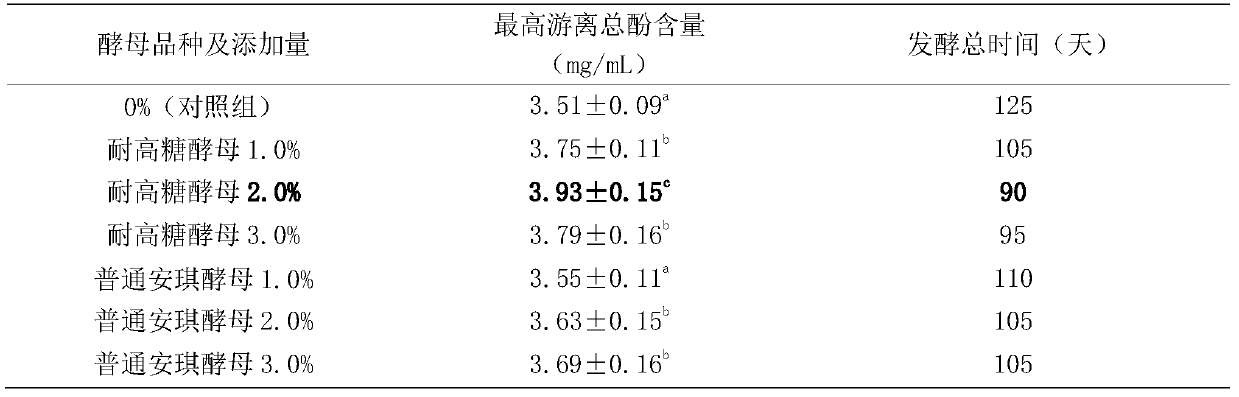

[0063] 3. Mold aerobic pre-fermentation: Add 1200mL Aspergillus niger liquid strain and 1200mL Aspergillus oryzae liquid strain equivalent to the weight of Amla emblica into the stainless steel fermenter, stir evenly; pass sterile air...

Embodiment 2

[0070] 1. Treatment of emblica and Sydney: select fresh, non-rotten and non-mildew emblica, a small wild fruit of emblica in Puning, Guangdong Province, 30 kg, and 20 kg of Sydney, wash by hand with tap water, and dry the surface moisture naturally in a cool place .

[0071] 2. Shallow cutting treatment of emblica and Sydney whole fruit: use a clean cutting machine with adjustable blade height to cut the surface of emblica and snow pear, and adjust the blade height so that the cutting depth of the pulp is about 1.5-2mm . Immediately, transfer the cut emblica on the surface to a sterilized, temperature-controllable, agitating, sealable, interlayer stainless steel fermenter (100L); mix emblica and pear (3:2) After homogenization, the contents of free amino acids and free polyphenols were measured to be 1.77 mg / g and 5.30 mg / g, respectively.

[0072] 3. Pre-fermentation: Add 1,000 mL of Aspergillus niger liquid strain and 1,000 mL of Aspergillus oryzae liquid strain equivalent ...

Embodiment 3

[0079] 1. Cleaning of emblica and tangli: select 500 kg of fresh, non-rotten, and mildew-free wild small fruit emblica in Puning, Guangdong, and 100 kg of wild tangli in Meizhou, and use tap water and a blast cleaning machine (cleaning) Amount of 0.5t / h) for cleaning, and then use a blower dryer to dry the surface moisture of the fruit.

[0080] 2. Shallow cutting of emblica and Tang pear skin: use a clean cutting machine with adjustable blade height to cut the skin of emblica and sugar pear, adjust the height of the blade so that the cutting depth of the pulp is about 1.5-2mm. Immediately, transfer the cut emblica and Tangli to a sterilized, temperature-controlled, stirring function, sealable stainless steel fermenter with interlayer (1200 L); 5:1) after mixing, the contents of free amino acid and free polyphenol were measured to be 2.87mg / g and 9.30mg / g respectively.

[0081] 3. Pre-fermentation: Add 18L liquid strains of Aspergillus niger and 18L liquid strains of Aspergil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com