Preparation method of nano calcium carbonate capable of stably suspending and dispersing in aqueous solution

A technology of nano-calcium carbonate and aqueous solution, applied in the direction of calcium carbonate/strontium/barium, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as reducing the surface energy of nano-calcium carbonate grains, and achieve expanded use range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of preparation method of the nano-calcium carbonate of stable suspension dispersion in aqueous solution, comprises the steps: add mass concentration in carbonization tower and be 8%, the calcium hydroxide suspension that temperature is 25 ℃, pass into carbon dioxide gas (CO 2content is 30%) to reaction slurry pH=6.5 to obtain nano-calcium carbonate slurry, and then carry out 5min overcarbonization to obtain nano-calcium carbonate cooked slurry; place nano-calcium carbonate cooked slurry in a sealed container, add calcium carbonate dry basis 1.0% ethanol, stirring and modifying for 1 hour, the modification temperature is 120° C. to obtain a modified nano-calcium carbonate slurry, which is dehydrated by pressure filtration, dried, and pulverized to obtain a nano-calcium carbonate product.

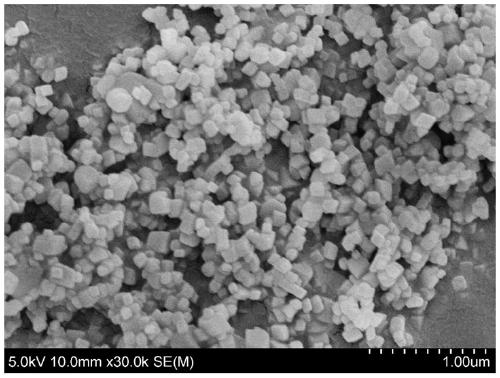

[0040] From figure 1 It can be seen that the nano-calcium carbonate prepared in Example 1 is a monodisperse cube, which is conducive to dispersion and suspension in aqueous solu...

Embodiment 2

[0042] A preparation method of nano-calcium carbonate stably suspended and dispersed in an aqueous solution, comprising the steps of: configuring a calcium hydroxide suspension with a mass concentration of 9% and a temperature of 15° C., adding it to a carbonization tower, and then feeding carbon dioxide gas (CO 2 content is 30%) to reaction slurry pH=7.0 to obtain nano-calcium carbonate slurry, and then carry out 10min overcarbonization to obtain nano-calcium carbonate cooked slurry; place nano-calcium carbonate cooked slurry in a sealed container, add ethanol and ethylene glycol , the addition of ethanol and ethylene glycol is 0.5% of the dry mass of calcium carbonate, stirring and modifying for 2 hours, and the modification temperature is 100°C to obtain a modified nano-calcium carbonate slurry, which is then centrifuged and dehydrated and dried , crushed to obtain nano calcium carbonate products.

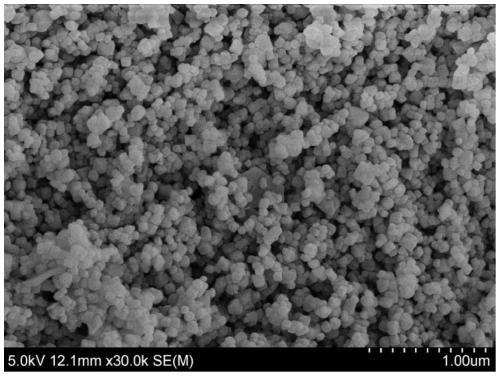

[0043] From figure 2 It can be seen that the nano-calcium carbonate parti...

Embodiment 3

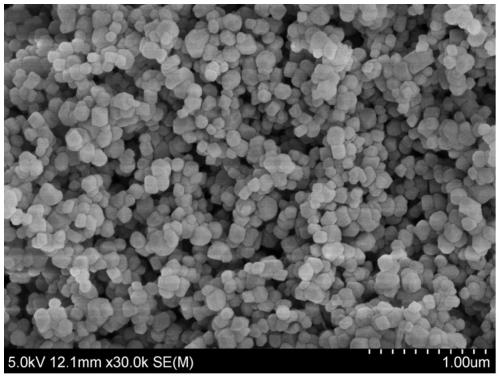

[0045] A kind of preparation method of the nano-calcium carbonate of stably suspending and dispersing in aqueous solution, comprises the following steps: the calcium hydroxide suspension liquid that configuration mass concentration is 10%, temperature is 20 ℃, adds in the carbonization tower, passes into carbon dioxide gas (CO 2 content is 30%) to the reaction slurry pH=6.0 to obtain nano-calcium carbonate slurry, and then carry out 8min overcarbonization to obtain nano-calcium carbonate cooked slurry; place nano-calcium carbonate cooked slurry in a sealed container, add ethylene glycol methyl acetate Ether and crotyl alcohol, the addition of the acetic acid ethylene glycol methyl ether is 0.6% of the dry basis of calcium carbonate, the addition of the crotyl alcohol is 0.8% of the dry basis of calcium carbonate, stirring and modifying for 4h, modifying The temperature is 90°C to obtain the modified nano-calcium carbonate slurry, which is then dehydrated by centrifugation, drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com