Non-metal grinding and polishing liquid

A polishing liquid and non-metallic technology, which is applied in the direction of polishing compositions containing abrasives, etc., can solve problems such as cake formation, insufficient suspension stability, and affect processing quality, and achieve the effect of stable suspension dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

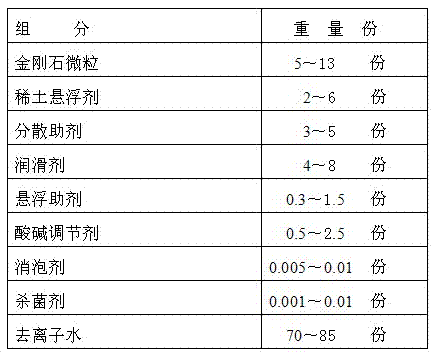

[0016] A kind of non-metallic grinding and polishing liquid comprises polycrystalline diamond particles, rare earth suspending agent, polypropylene glycol, isomeric tridecyl alcohol atactic polyether, agar, xanthan gum, sodium carbonate, sodium hydroxide, organic silicon defoamer, benzene Diisothiazol-3-one and deionized water, each component and its parts by weight (kg) are:

[0017]

[0018] Under stirring conditions, 4 kg of polypropylene glycol, 4 kg of isomeric tridecanol atactic polyether, 4 kg of rare earth suspending agent, 0.7 kg of agar and 0.3 kg of xanthan gum, 0.005 kg of silicone defoamer, 0.01 Add one kilogram of benzisothiazol-3-one to 80 kilograms of deionized water, and stir vigorously for 1.0 hour. After all components are dissolved evenly, then use 1.2 kilograms of sodium carbonate and 0.3 kilograms of sodium hydroxide to adjust the pH of the system to 10~ 11. Finally, add 9 kg of polycrystalline diamond particles and stir for 0.5 hour, then stop stirrin...

Embodiment 2

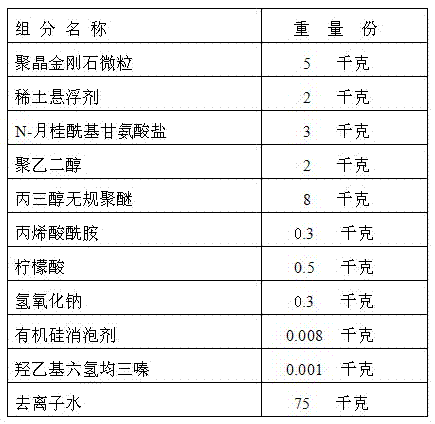

[0020] A non-metallic grinding and polishing liquid comprises polycrystalline diamond particles, rare earth suspending agent, N-lauroyl glycinate, polyethylene glycol, glycerol random polyether, acrylic acid amide, citric acid, sodium hydroxide, organosilicon disinfectant Foaming agent, hydroxyethylhexahydro-s-triazine and deionized water, each component and its parts by weight (kg) are:

[0021]

[0022] Under stirring conditions, 3 kg of N-lauroyl glycinate, 2 kg of polyethylene glycol, 8 kg of glycerol random polyether, 2 kg of rare earth suspending agent, 0.3 kg of acrylic acid amide, and 0.008 kg of organic silicon Foaming agent and 0.001 kg of hydroxyethylhexahydro-s-triazine were added to 75 kg of deionized water, and vigorously mechanically stirred for 0.5 hours. After the components were uniformly dissolved, 0.5 kg of citric acid and 0.3 kg of sodium hydroxide were used to adjust the system PH9~10, finally add 5 kg of polycrystalline diamond particles and stir for ...

Embodiment 3

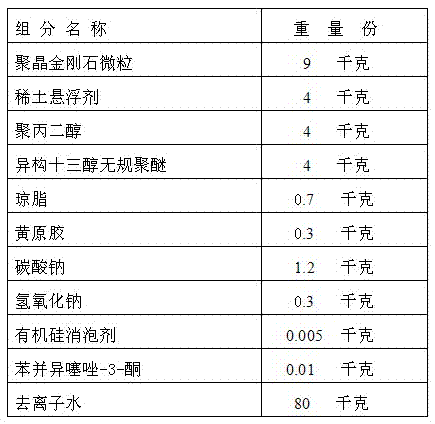

[0024] A non-metallic grinding and polishing liquid including nano-diamond particles, rare earth suspending agent, N-palmitoyl alanine salt, lauric acid random polyether, sodium diatomate, peach gum, octanoic acid, triethanolamine, monoethanolamine, organic silicon Defoamer, 5-chloromethylisothiazolinone and deionized water, each component and its parts by weight (kg) are:

[0025]

[0026] Under stirring conditions, 3 kg of N-palmitoyl alanine salt, 2 kg of polyethylene glycol, 6 kg of lauric acid random polyether, 6 kg of rare earth suspending agent, 1.0 kg of sodium diatomate, 0.5 kg Peach gum, 0.01 kg of silicone defoamer, 0.006 kg of 5-chloromethylisothiazolinone, were added to 85 kg of deionized water, and vigorously mechanically stirred for 0.5 hours. After the components were uniformly dissolved, 0.5 kg of octanoic acid acid, 1.6 kg of monoethanolamine and 0.4 kg of triethanolamine, adjust the pH of the system to 8-9, finally add 13 kg of polycrystalline diamond par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com