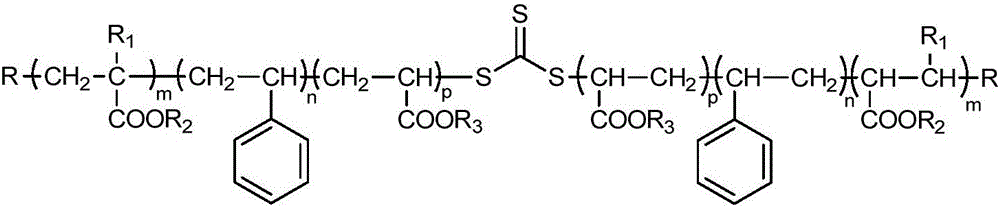

Block polymeric dispersant and preparation method and application thereof

A technology of block polymer and dispersant, applied in the fields of botanical equipment and methods, applications, chemical instruments and methods, etc., can solve the problems of inability to obtain polymer compounds, weak ionic strength, and wide product molecular weight distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

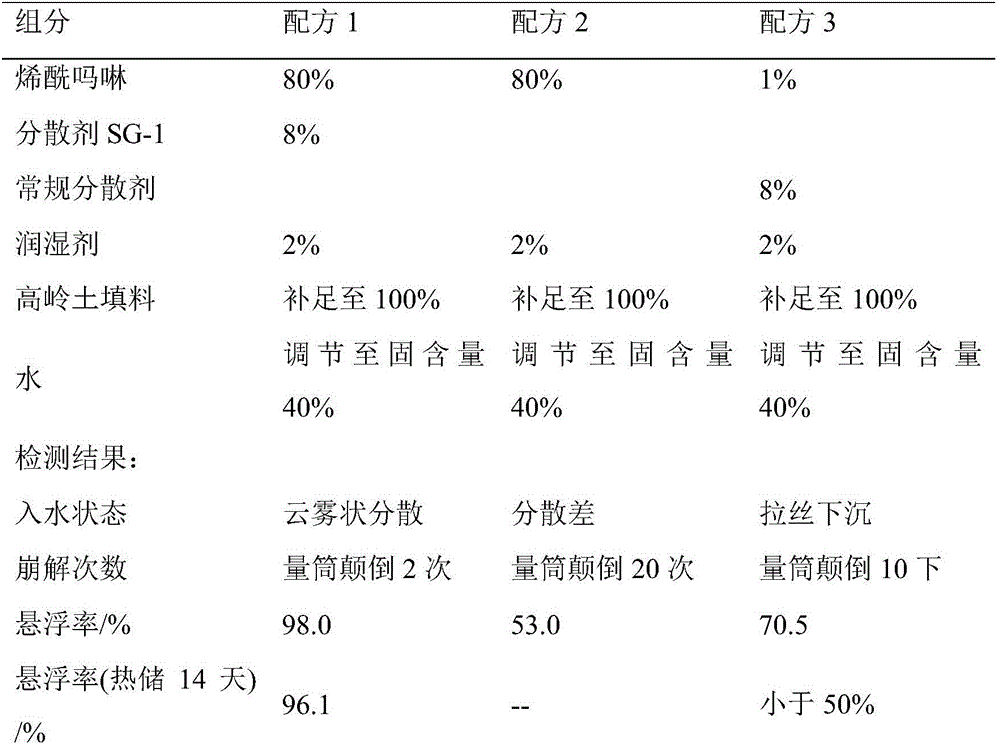

Examples

Embodiment 1

[0022] Monomer molar ratio: methacrylic acid MMA / polyethylene glycol methacrylate PEGMA / isooctyl acrylate EHA=1 / 1 / 2

[0023] Initiator: Benzoyl Peroxide BPO

[0024] Solvent: Isopropanol

[0025] Add 2 mmol of RAFT reagent, 0.1 mol of methacrylic acid and 0.1 mol of polyethylene glycol methacrylate PEGMA and 50 ml of isopropanol into a four-neck flask equipped with a stirrer, constant pressure drop tank, thermometer and condenser Solvent, stir and heat to 80°C, at this time the material melts, add 0.4mmol of initiator BPO in isopropanol solution dropwise within 30min, continue the reaction for 2h, add dropwise 0.1mmol of initiator BPO and 0.1mol of isooctyl acrylate in isopropyl alcohol Alcohol mixed solution, control the dropping time to 1h, continue to react for 2h after the reaction is completed, distill off the solvent under reduced pressure, neutralize with sodium hydroxide aqueous solution to pH 9-12, spray dry to obtain powder solid. That is the polymer dispersant SG-1....

Embodiment 2

[0027] Monomer molar ratio: methacrylic acid / styrene / butyl acrylate=2 / 1 / 1

[0028] Initiator: AIBN

[0029] Solvent: ethyl acetate

[0030] Add 2mmol of RAFT reagent, 0.2mol of methacrylic acid and 50ml of ethyl acetate into a four-necked flask equipped with a stirrer, a constant pressure drop tank, a thermometer and a condenser, stir and heat to 70°C, at this time the material melts, within 30min Add dropwise the ethyl acetate solution of 0.2mmol initiator AIBN, continue to react for 2h, add dropwise the ethyl acetate mixed solution of 0.2mmol initiator and 0.1mol styrene and 0.1mol butyl acrylate respectively, control the dropping time to be 1h, react After completion, the reaction was continued for 2 h, the solvent was distilled off under reduced pressure, neutralized with triethanolamine to a pH of 9-12, and spray-dried to obtain a powder solid. That is the polymer dispersant SG-2. The molecular weight is 27000, and the molecular weight distribution is 1.20.

Embodiment 3

[0032] Monomer molar ratio: maleic anhydride polyethylene glycol monomethyl ether (MPEG550) monoester / styrene / isobutyl acrylate=2 / 1 / 1

[0033] Initiator: 4,4-Azobis(4-cyanovaleric acid) ACVA

[0034] Solvent: ethanol

[0035] Add 2 mmol of RAFT reagent, 0.2 mol of maleic anhydride polyethylene glycol monomethyl ether and 50 ml of ethanol into a four-necked flask equipped with a stirrer, a constant pressure drop tank, a thermometer and a condenser tube, stir and heat to 80°C, at this time The material is melted, and the ethanol solution of 0.2mmol initiator ACVA is added dropwise within 30min, and the reaction is continued for 2h, and the ethanol mixed solution of 0.2mmol initiator, 0.1mol styrene and 0.1mol isobutyl acrylate is added dropwise, and the dropping time is controlled to be 1h After the reaction was completed, the reaction was continued for 2 h, the solvent was distilled off under reduced pressure, neutralized with aqueous sodium hydroxide solution to a pH of 9-12,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com