A kind of preparation method of sheet type high temperature resistant self-suspension plugging agent

A high-temperature-resistant, self-suspending technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of insufficient temperature resistance, difficult adjustment and control of thickness, poor suspension dispersion, etc., and achieves excellent heat resistance, suitable for Wide range, good heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

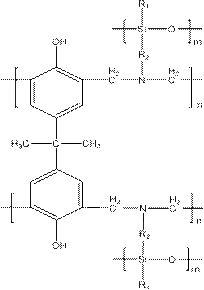

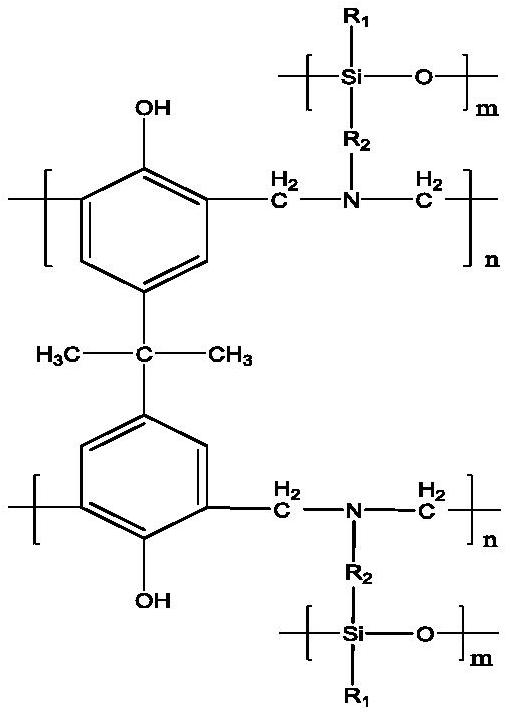

[0033] (1) Preparation of high temperature resistant thermosetting resin sheet: after 140g amino silicone oil and 162g formaldehyde aqueous solution (37%) were dispersed with 200ml dioxane respectively, put into the reaction kettle and stir and mix, and the temperature of the reaction kettle was controlled below 10°C, slowly adding 228g of bisphenol A; after mixing evenly, heat up and reflux for 3 hours; then stop the reaction, evaporate the solvent to obtain a viscous prepolymer liquid, add 1% hydrochloric acid to the obtained prepolymer liquid, mix well, and then pack Put it into a mold, heat it up to 220°C, and react for 6 hours to obtain a high temperature resistant thermosetting resin sheet;

[0034] (2) Surface graft modification of the high temperature resistant thermosetting resin sheet: after the surface of the high temperature resistant thermosetting resin sheet obtained in step (1) is activated with sulfuric acid, it is dispersed in an aqueous solution, and 10% of th...

Embodiment 2

[0036] (1) preparation of high temperature resistant thermosetting resin sheet: after 154g amino silicone oil and 180g formaldehyde aqueous solution (37%) were dispersed with 220ml dioxane respectively, put into the reaction kettle and stir and mix, and the temperature of the reaction kettle was controlled below 10 ° C, slowly adding 240g Bisphenol A. After mixing uniformly, the temperature was raised, and the reaction was refluxed for 4 hours. The reaction was then stopped and the solvent was evaporated to give a viscous prepolymer liquid. 1.5% hydrochloric acid was added to the obtained prepolymer liquid, mixed evenly, and then loaded into a mold, heated to 250° C., and reacted for 5 hours to obtain the high-temperature-resistant thermosetting resin sheet of the present invention;

[0037] (2) Surface graft modification of high temperature resistant thermosetting resin sheet: after the surface of the high temperature resistant thermosetting resin sheet obtained in step (1) ...

Embodiment 3

[0039] (1) Preparation of high temperature resistant thermosetting resin sheet: after 168g amino silicone oil and 190g formaldehyde aqueous solution (37%) were dispersed with 250ml dioxane respectively, put into the reaction kettle and stir and mix, and the temperature of the reaction kettle was controlled below 10 ° C, slowly adding 273g of bisphenol A; after mixing uniformly, the temperature was raised and refluxed for 5 hours and then the reaction was stopped, and the solvent was evaporated to obtain a viscous prepolymer liquid, 2% hydrochloric acid was added to the obtained prepolymer liquid, and the mixture was uniformly mixed. In the mold, the temperature is raised to 250°C, and the reaction is performed for 4 hours to obtain the high temperature resistant thermosetting resin sheet of the present invention;

[0040](2) Surface graft modification of the high temperature resistant thermosetting resin sheet: after the surface of the high temperature resistant thermosetting r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com