Environment-friendly polyurethane track material formula

A technology of polyurethane and runway, applied in the field of polymer materials, can solve the problems of short service life, poor mechanical properties of elastomers, etc., and achieve the effect of good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

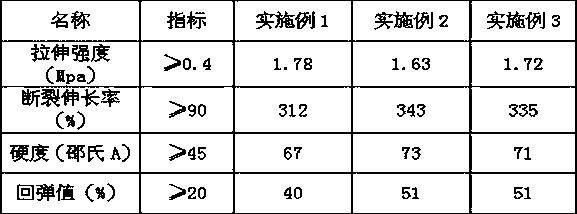

Examples

Embodiment 1

[0016] An environment-friendly polyurethane runway material is prepared by mixed reaction of component A, component B and a catalyst.

[0017] Preparation of Component A: Add 100 parts of polyether polyol into the reaction kettle, stir and heat up to 120°C, vacuum dehydrate for 2 hours, cool down to 60°C, add 60 parts of MDI, heat up to 80°C and react at constant temperature for 2 hours, down to Room temperature, discharge, sealed storage, spare.

[0018] Preparation of component B: In terms of weight fraction, mix 100 parts of polyether polyol, 0.07 parts of MOCA, and 54 parts of DOP evenly into the reaction kettle, stir and heat up to 120°C, vacuum dehydrate for 2 hours, cool down to room temperature, and add 192 parts Filling, discharge, sealed storage, standby. Wherein the filler includes 96% talcum powder and 4% colorant iron oxide red.

[0019] Preparation of polyurethane runway material sample: at room temperature, uniformly mix components A and B at a ratio of 1:5, a...

Embodiment 2

[0021] An environment-friendly polyurethane runway material is prepared by mixed reaction of component A, component B and a catalyst.

[0022] Preparation of Component A: Add 100 parts of polyether polyol into the reaction kettle, stir and heat up to 120°C, vacuum dehydrate for 2 hours, cool down to 60°C, add 60 parts of MDI, heat up to 80°C and react at constant temperature for 2 hours, down to Room temperature, discharge, sealed storage, spare.

[0023] Preparation of component B: In terms of weight fraction, mix 100 parts of polyether polyol, 0.07 parts of M-CDEA, and 54 parts of DOP evenly into the reaction kettle, stir and heat up to 120°C, vacuum dehydrate for 2 hours, cool down to room temperature, and add 192 parts of stuffing, discharging, sealed storage, standby. Wherein the filler includes 96% talcum powder and 4% colorant iron oxide red.

[0024] Preparation of polyurethane runway material sample: at room temperature, uniformly mix components A and B at a ratio o...

Embodiment 3

[0026] An environment-friendly polyurethane runway material is prepared by mixed reaction of component A, component B and a catalyst.

[0027] Preparation of component A: Add 100 parts of polyether polyol into the reaction kettle, stir and heat up to 120°C, vacuum dehydrate for 2 hours, cool down to 60°C, add 60 parts of MDI, heat up to 80°C and react at constant temperature for 2 hours, then drop to Room temperature, discharge, sealed storage, spare.

[0028] Preparation of component B: In terms of weight fraction, mix 100 parts of polyether polyol, 0.07 parts of 4,4'-bis-sec-butylaminodiphenylmethane, and 54 parts of DOP into the reaction kettle, stir and heat up to 120°C , dehydrated in vacuum for 2 hours, lowered to room temperature, added 192 parts of filler, discharged, sealed and stored for later use. Wherein the filler includes 96% talcum powder and 4% colorant iron oxide red.

[0029] Preparation of polyurethane runway material sample: at room temperature, uniformly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com