Environment-friendly insole fiberboard processing method

A processing method and fiberboard technology, applied in the agricultural field, can solve problems such as unfavorable environmental protection, waste wood pulp, etc., and achieve the effects of stable performance, high density and high quality, and uniform fiber distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

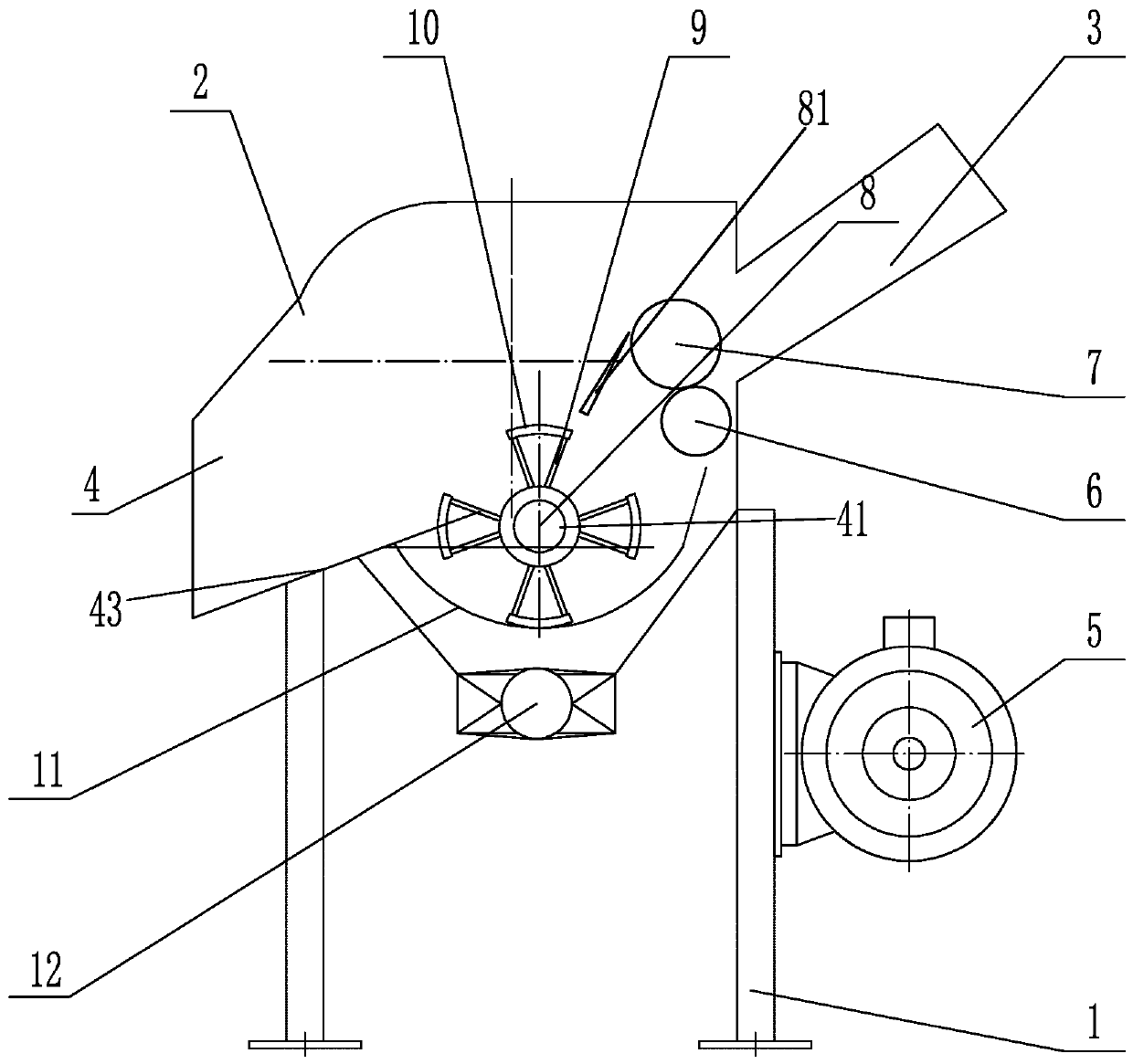

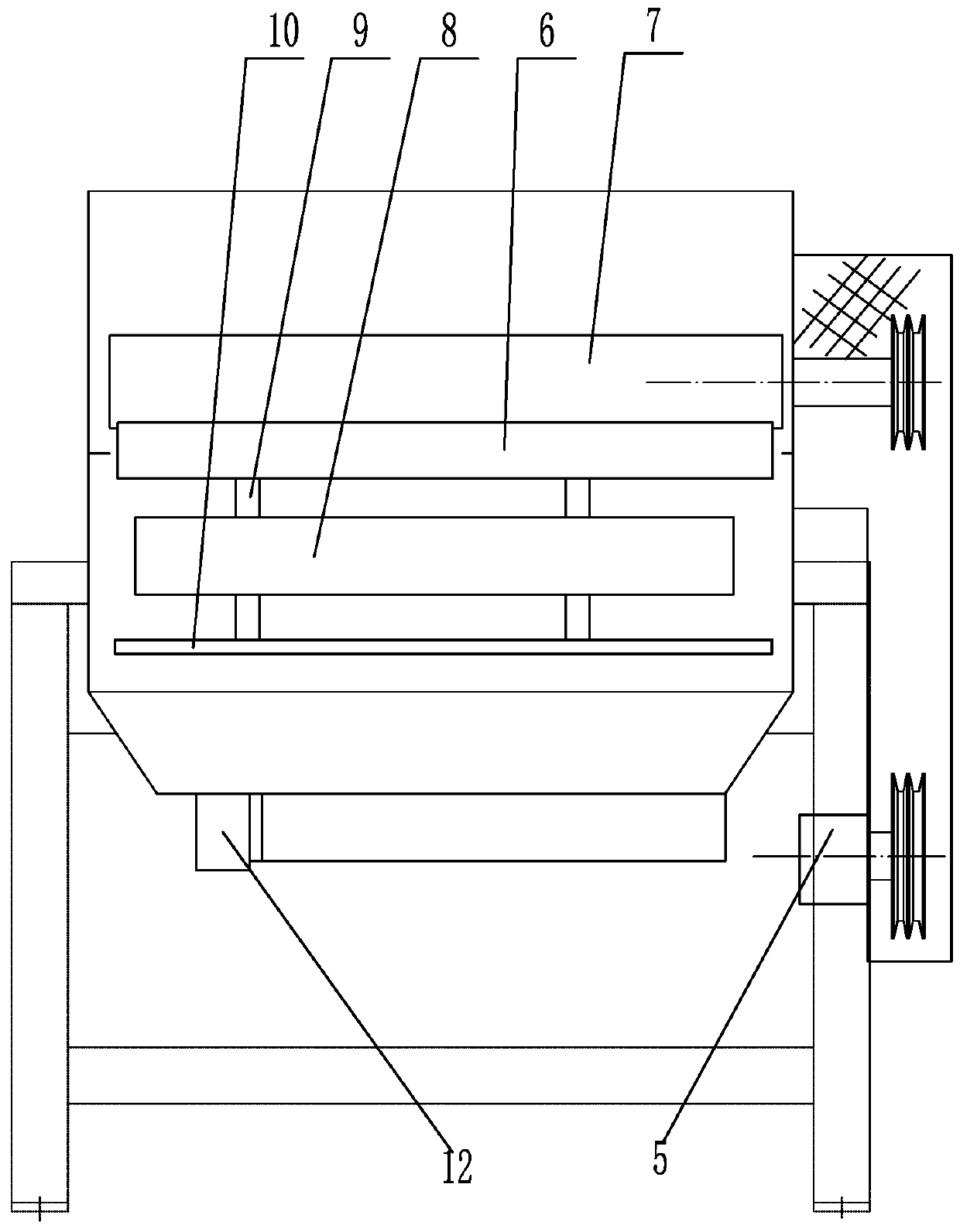

Method used

Image

Examples

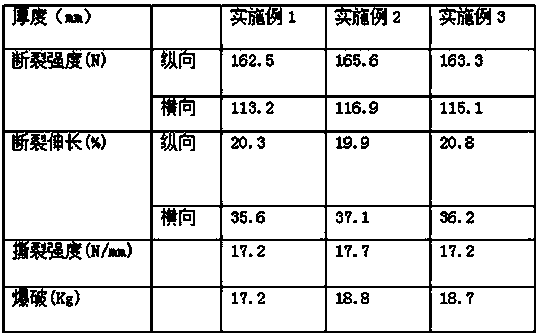

Embodiment 1

[0018] Embodiment 1: put the collected straw into the grass washing and impurity removal machine, and carry out the straw washing and impurity removal, which can wash the soil mixed with the straw, and remove impurities, leaves and other wastes in the straw; use the conveyor to send the cleaned straw to Enter the grass cutting machine, clean the straw and cut the straw, cut the straw into a length of 25mm according to the process requirements; use the screw conveyor to rub the chopped straw, and send the chopped straw to the silk rubbing machine to knead into fibers In this process, water should be added appropriately to ensure that the fiber dryness is 20%.

[0019] Grind the kneaded straw fiber. This process requires two high-consistency mills (high-consistency refiners) to be connected in series, and the screw conveyor is used to send the kneaded straw fiber to the first high-consistency mill, and water is added to grind the straw fiber. Add 90% water, automatically heat up...

Embodiment 2

[0020] Embodiment 2: the above method of obtaining straw fiber raw materials is the same; get 43 parts of straw fiber, 4 parts of water-based polyurethane, 0.02 part of blocked water-based isocyanate crosslinking agent, 0.03 part of carboxylated styrene-butadiene latex, 8 parts of fiber cotton and 15 parts of wood pulp, Proper amount of water is mixed to make raw materials. The raw materials are formed into thick sheets by multi-net molding. The thick sheets are pressed out of water, dried and cut to make 2.0mm fiberboards respectively. The remaining water is recycled and sedimented for reuse.

Embodiment 3

[0021] Embodiment 3: the above method of obtaining straw fiber raw materials is the same; get 47 parts of straw fiber, 5 parts of water-based polyurethane, 0.03 part of blocked water-based isocyanate crosslinking agent, 0.035 part of carboxylated styrene-butadiene latex, 9 parts of fiber cotton and 16 parts of wood pulp, Proper amount of water is mixed to make raw materials. The raw materials are formed into thick sheets by multi-net molding. The thick sheets are pressed out of water, dried and cut to make 2.0mm fiberboards respectively. The remaining water is recycled and sedimented for reuse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com