High-strength fireproof insulation board with tongue-and-groove structure and manufacturing method of high-strength fireproof insulation board

A fire-proof insulation board, high-strength technology, applied in the directions of heat preservation, fire prevention, chemical instruments and methods, etc., can solve the problems of difficulty in meeting the requirements of cavity structure, rock wool cannot be filled with tongue and groove, energy loss at tongue and groove, etc. Novel process, good thermal insulation performance, and the effect of improving fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

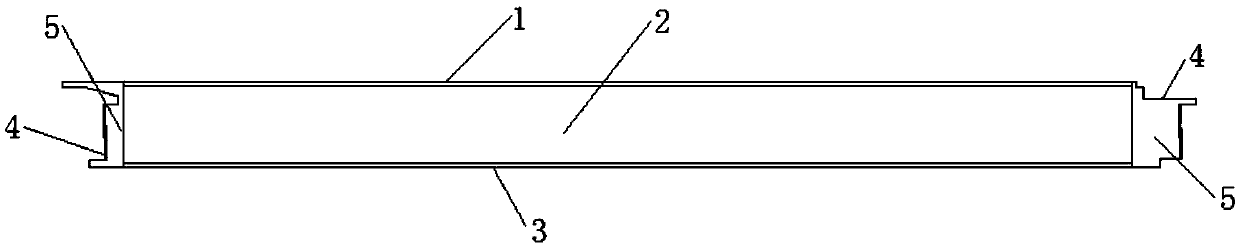

[0041] Such as figure 1 As shown, the high-strength fireproof insulation board with tongue-and-groove structure, the insulation board includes the upper layer color steel plate 1, the ordinary rock wool board 2 and the lower layer color steel plate 3, and the ordinary rock wool board 2 is located between the upper layer color steel plate 1 and the lower layer color steel plate 3 In between, the upper surface and the lower surface of the common rock wool board 2 are respectively bonded with the upper layer color steel 1 and the lower layer color steel 3, and the upper layer color steel 1 and the lower layer color steel 3 are crimped at the left and right ends to form a groove 4, a groove 4 There is a cavity, and a high-density rock wool filling block 5 is arranged in the cavity, and the high-density rock wool filling block 5 is filled with the cavity of the tongue and groove, and the left and right ends of the ordinary rock wool board 2 are flush cut surfaces, and the high-dens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com