Diameter variable double high-pressure stir-spray pile and diameter variable method thereof

A technique of mixing and spraying piles and double high pressure, which is applied in the direction of drilling equipment and methods, sheet pile walls, earthwork drilling and mining, etc., which can solve the problems of increasing the difficulty of on-site operation and adjustment, unfavorable stability of the connection structure of mixing and spraying piles, time-consuming and laborious and other problems, to achieve the effect of stable connection structure between the drill bit and the drill pipe, simple and easy operation of variable diameter, and guaranteed work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

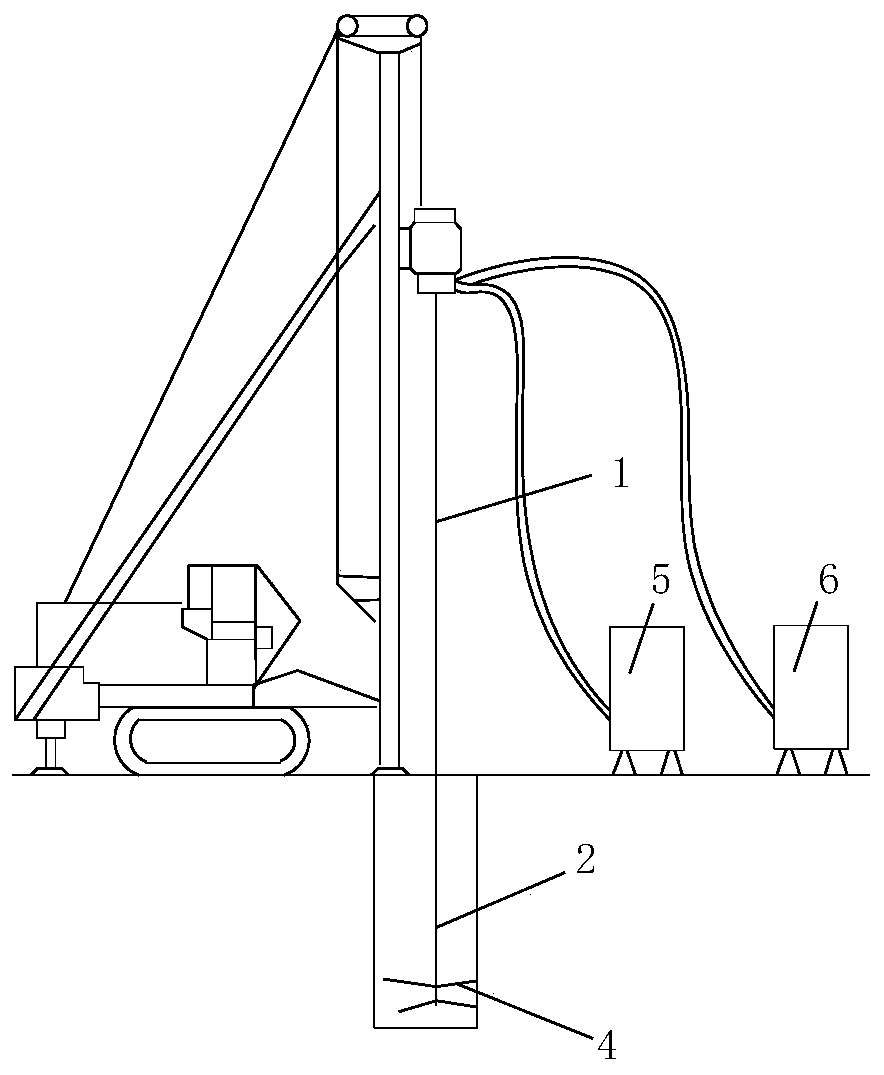

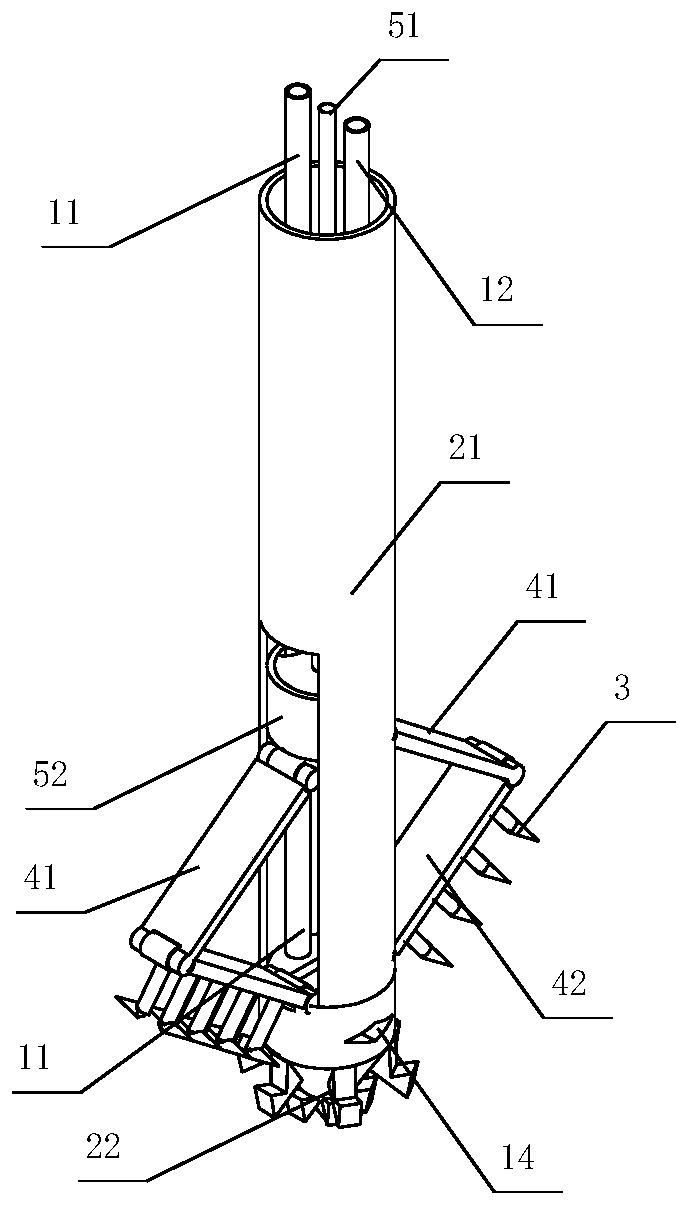

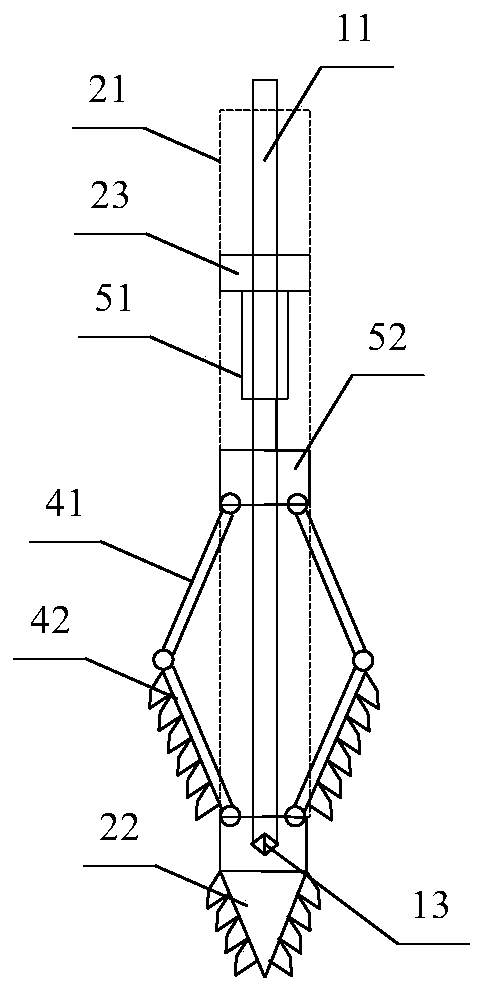

[0038] Example 1, such as Figure 1 to Figure 7 As shown, the variable-diameter double-high-pressure mixing pile includes:

[0039] Drill rod 1 and drill bit 2 connected to the end of drill rod 1;

[0040] The high-pressure pump 6 connects and delivers compressed air and cement slurry to the high-pressure air pipe 11 and the high-pressure cement slurry pipe 12 from the outside, and the high-pressure air pipe 11 and the high-pressure cement slurry pipe 12 inside the drill pipe 1 and the drill bit 2 are connected;

[0041] The drill bit 2 has an outer casing 21 connected to the drill pipe 1, and the connection method can be welding, plugging or bolt connection; an end 22 is connected to the end of the outer casing 21;

[0042] A fixed base 23 for the high-pressure air pipe 11 and the high-pressure cement slurry pipe 12 to penetrate is arranged inside the outer sleeve 21, and a hydraulic rod 51 is installed on the fixed base 23, and the hydraulic rod 51 drives and connects the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com