Full-hydraulic non-servo rock creep test device and method

A creep test and full hydraulic technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of large environmental pollution, high use and maintenance requirements, and high use and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

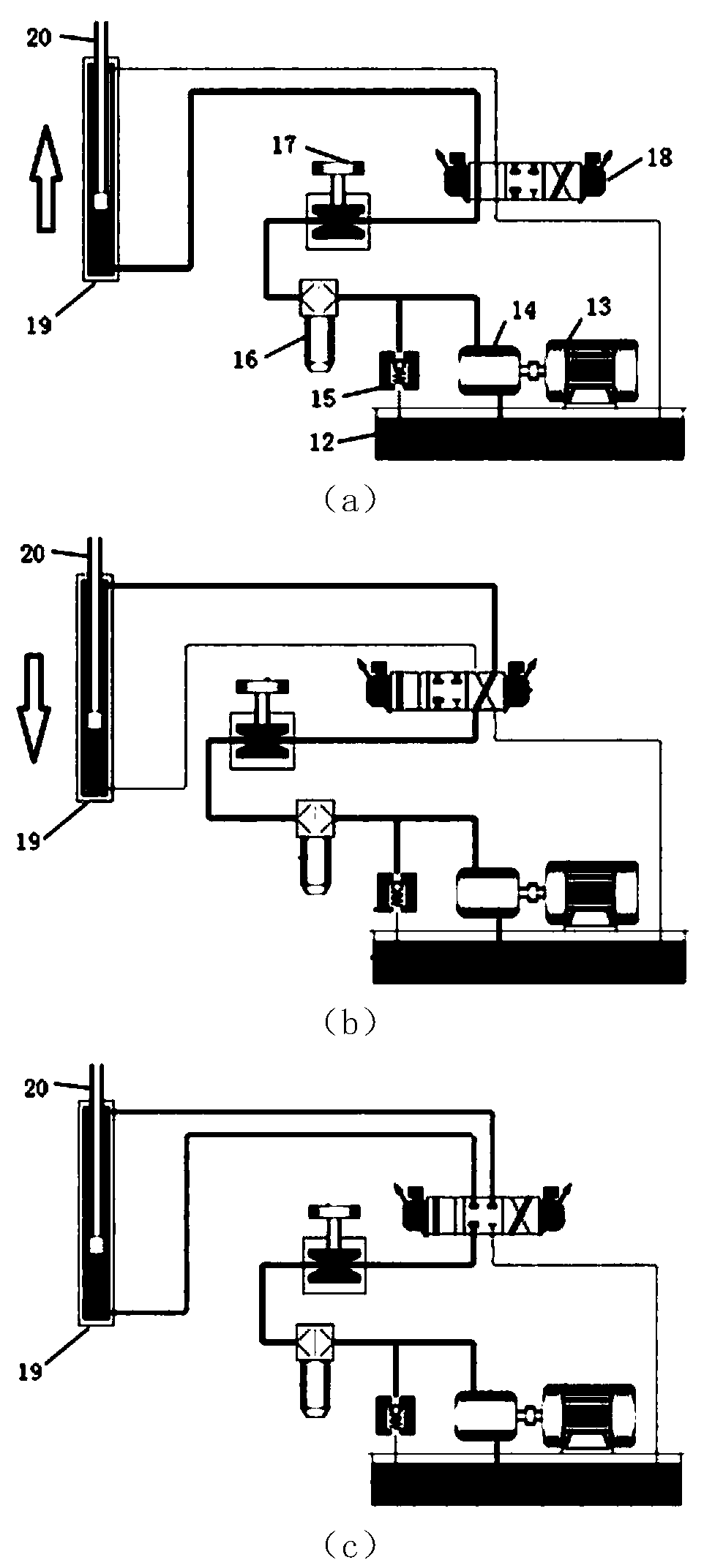

[0095] Such as Figure 5 , 6 As shown, a fully hydraulic non-servo rock creep test device includes a disc-sealed single-acting loading cylinder 37 and a non-servo hydraulic pressure stabilization system, and the disc-sealed single-acting loading cylinder 37 includes a loading plunger 22, Housing 23, disc-shaped rubber seal 24, venting plug 21, pressing plate 28 and base 25, the loading plunger 22 is placed in the housing 23, the housing 23 is installed on the base 25, the The disc-shaped rubber seal 24 is provided between the housing 23 and the base 25, the center of the disc-shaped rubber seal 24 is provided with a round hole, and the center of the loading plunger 22 is provided with a through hole. The center of the pressing plate 28 is provided with an air release hole, and the pressing plate 28 presses and installs the disc-shaped rubber seal 24 on the loading plunger 22, and the venting plug 21 is used to plug the passage hole; the base 25 is provided with a liquid inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com