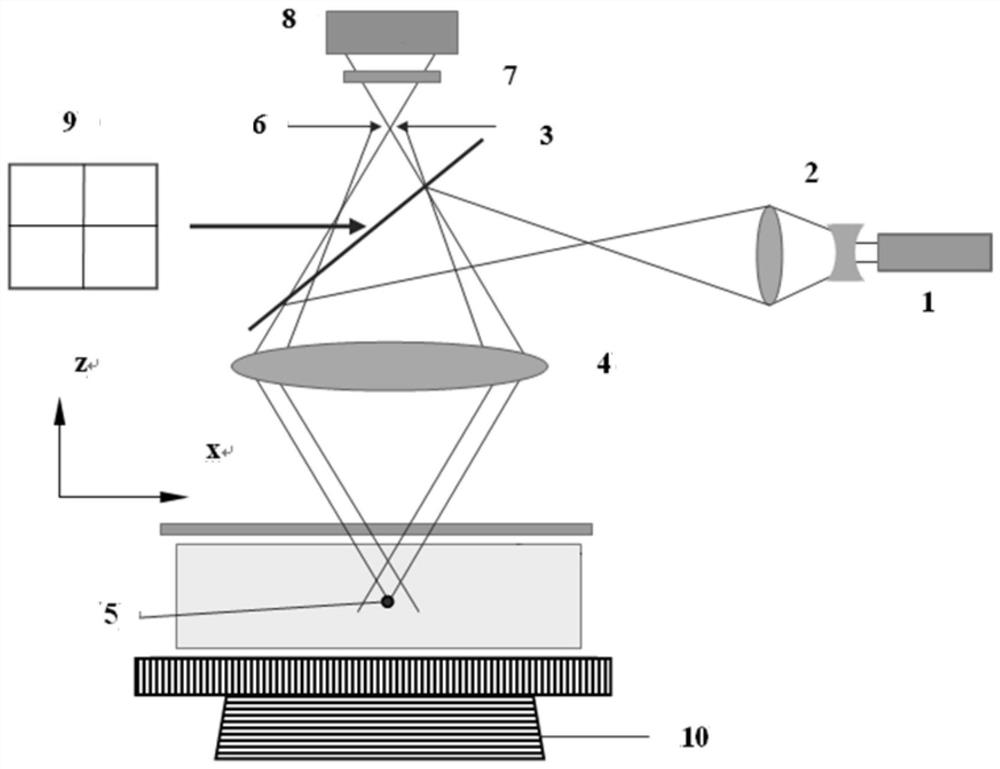

Method for Measuring Medium Surface Roughness Using Confocal Laser Scanning Microsystem

A technology of laser scanning and microscopic systems, which is applied in the direction of measuring devices, optical devices, and material analysis through optical means, can solve problems such as irregular space shape detection, medium structure damage, difficulties, etc., and achieve suitable high precision Measuring, increasing productivity, cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

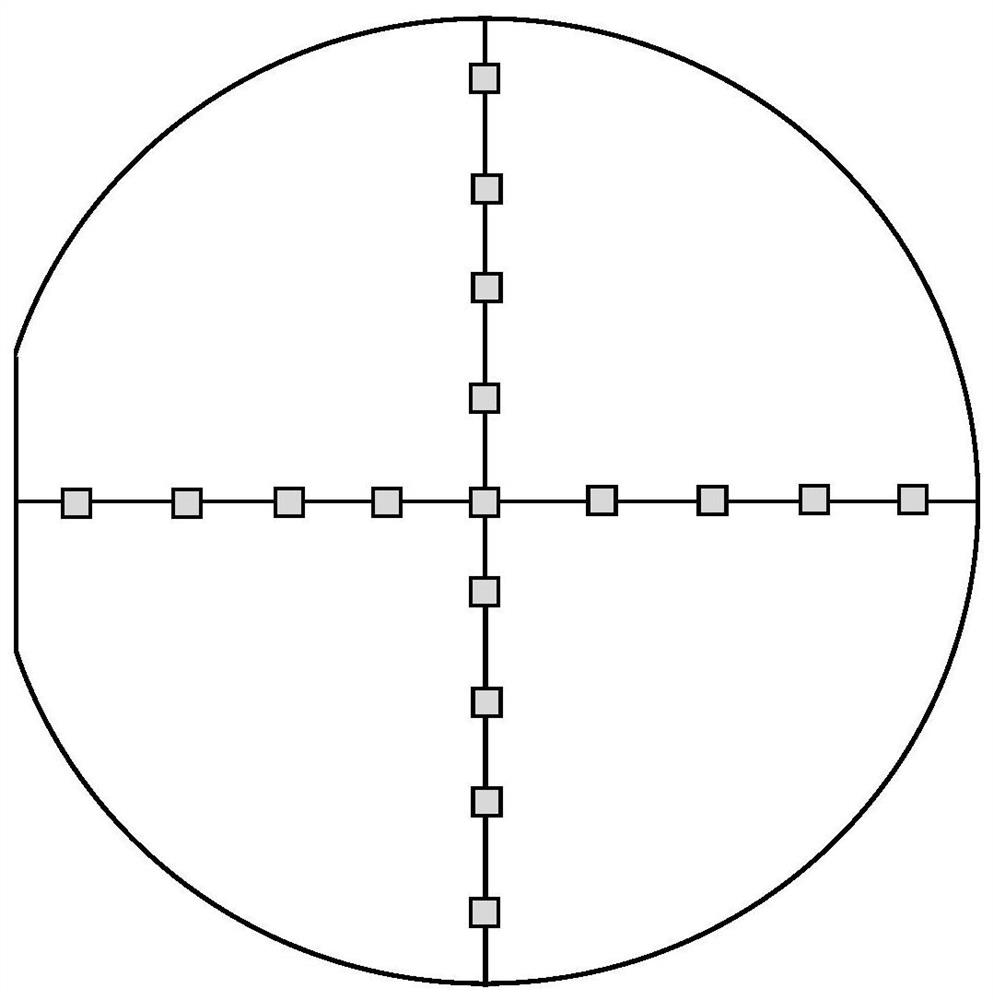

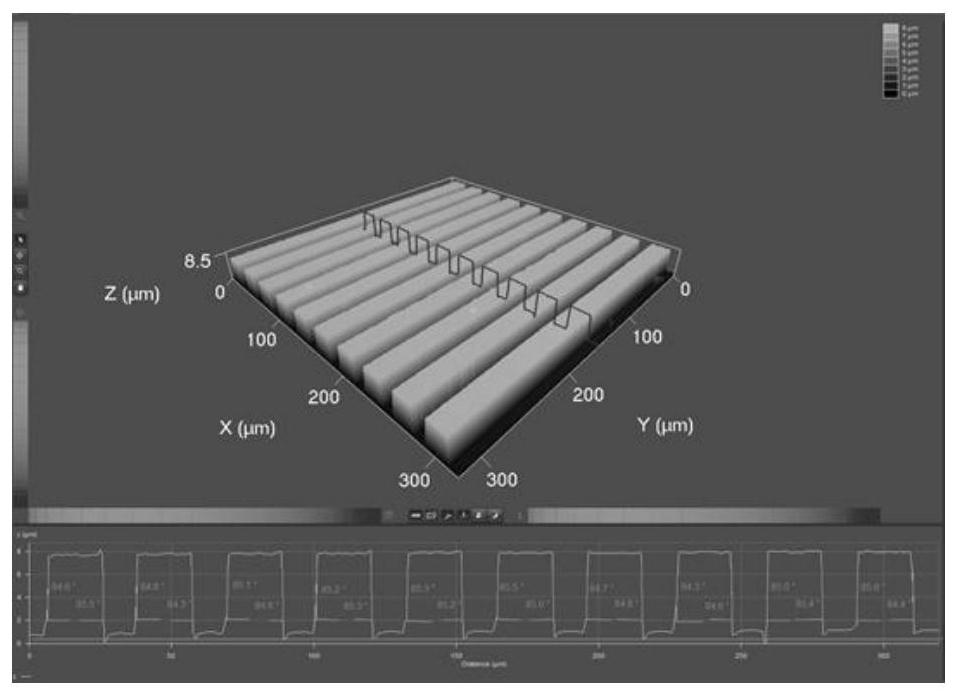

[0053] Example 1: For the reconstructed scanned graphics, such as Figure 7 As shown, select 10 sampling areas at different positions on the same waveguide or structural channel to analyze the roughness of the side wall, that is, m=1, n=10, and obtain the peak value, deep valley, and total value of each subdivided sampling area. height, and then average the waveguide sidewall roughness shown in Table 1 for all selected locations.

[0054] n PSp(μm) PSv(μm) PSt(μm) 1 0.205 0.232 0.437 2 0.289 0.183 0.472 3 0.29 0.365 0.655 4 0.232 0.292 0.525 5 0.301 0.262 0.563 6 0.273 0.144 0.416 7 0.291 0.243 0.534 8 0.485 0.171 0.656 9 0.35 0.187 0.537 10 0.348 0.144 0.492 AVG 0.3064 0.2223 0.5287

[0055] Table 1

Embodiment 2

[0056] Example 2: For the reconstructed scanned graphics, such as Figure 8 As shown, select multiple waveguide or structure channels, select a waveguide transverse area and conduct subdivided sampling analysis of this area in 10 areas, that is, m=10, n=10, and then calculate for all waveguide channels or structures average value. As shown in table 2.

[0057] m PSp(μm) PSv(μm) PSt(μm) 1 0.403 0.127 0.53 2 0.568 0.144 0.712 3 0.549 0.122 0.671 4 0.475 0.18 0.655 5 0.566 0.109 0.675 6 0.455 0.122 0.576 7 0.523 0.179 0.701 8 0.492 0.122 0.614 9 0.489 0.081 0.57 10 0.522 0.101 0.623 AVG 0.5042 0.1287 0.6327

[0058] Table 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com