Method, device and system for automatically identifying welding seam position based on square tube

A technology of automatic identification and welding seam position, applied in welding equipment, laser welding equipment, image data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

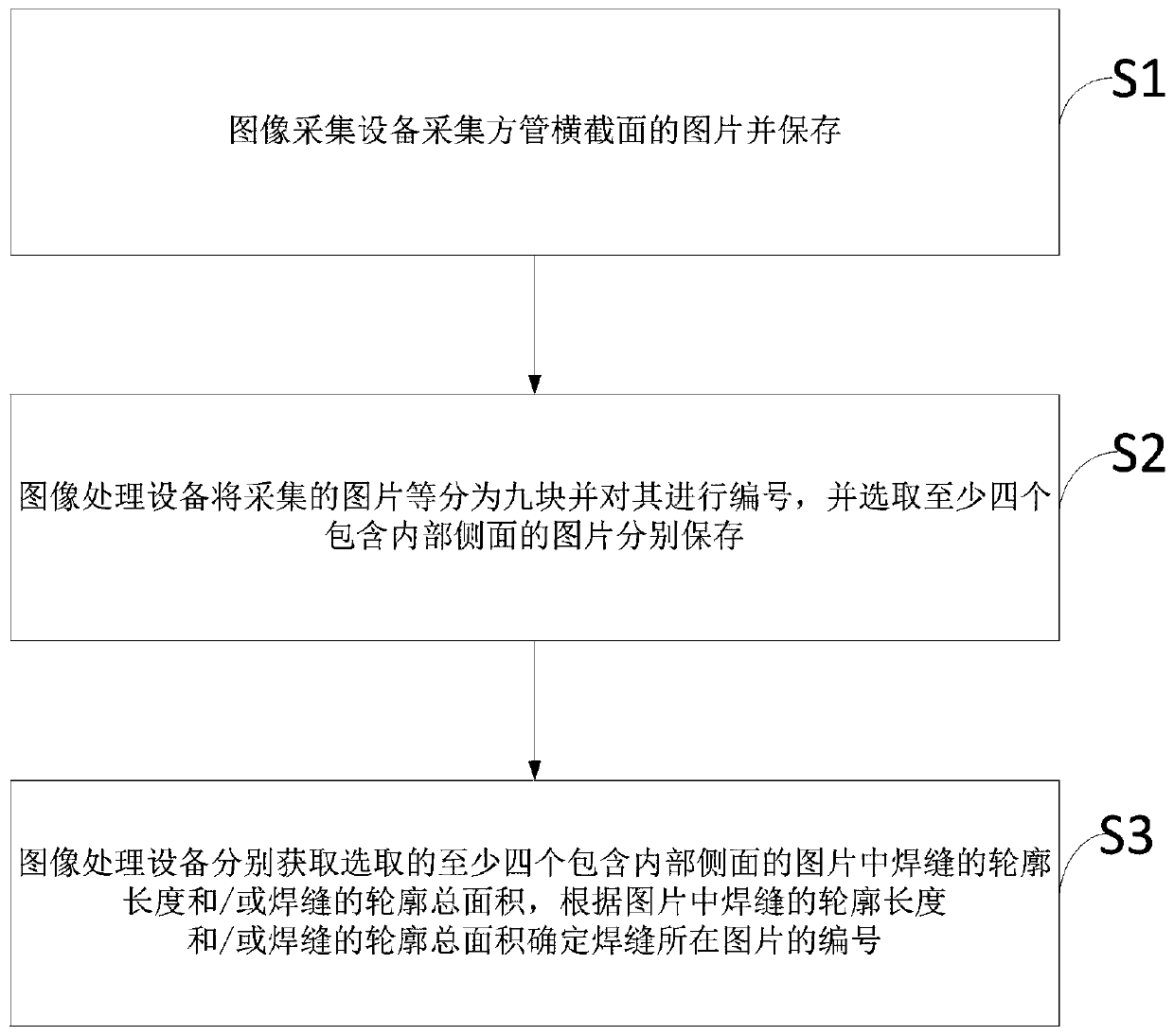

[0048] Such as figure 1Shown, the present invention provides a kind of method based on the automatic identification of square pipe weld position, comprising:

[0049] S1, the image acquisition device collects and saves the picture of the cross section of the square tube;

[0050] S2, the image processing device divides the collected pictures into nine equal parts and numbers them, and selects at least four pictures containing the inner sides and saves them respectively;

[0051] S3, the image processing device separately obtains the contour length and / or the total contour area of the weld in at least four selected pictures containing the internal side, according to the contour length and / or the total contour area of the weld in the picture Determines the number of the picture where the weld is located.

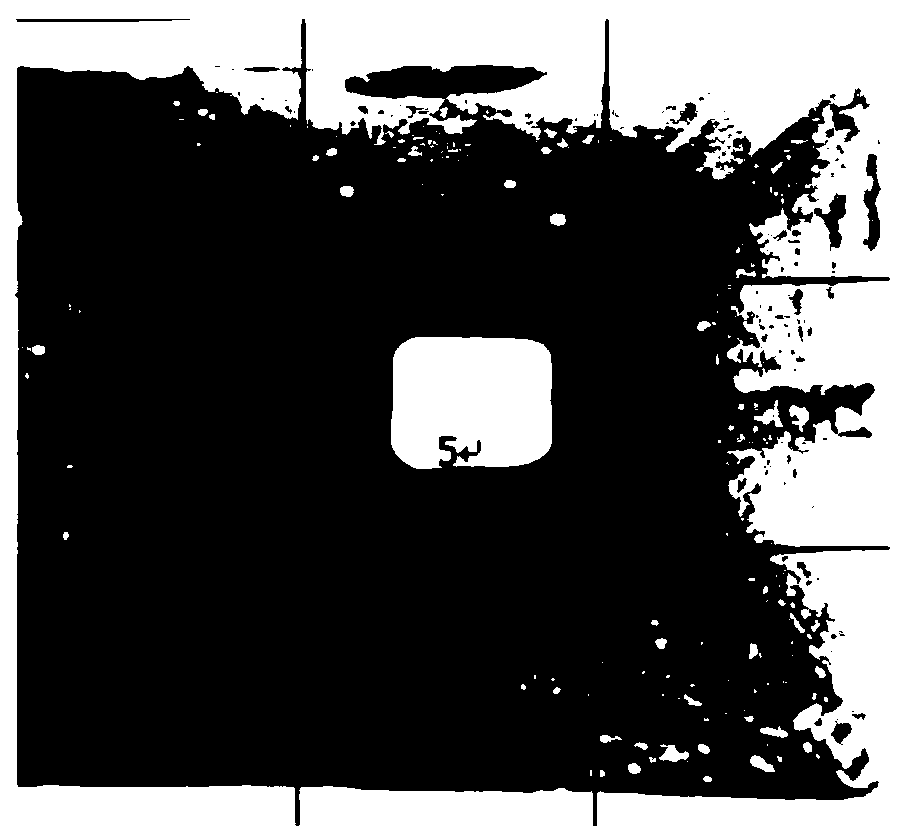

[0052] In step S1, the picture of the cross-section of the square pipe is collected at least including four sides inside the square pipe. In the embodiment of the presen...

Embodiment 2

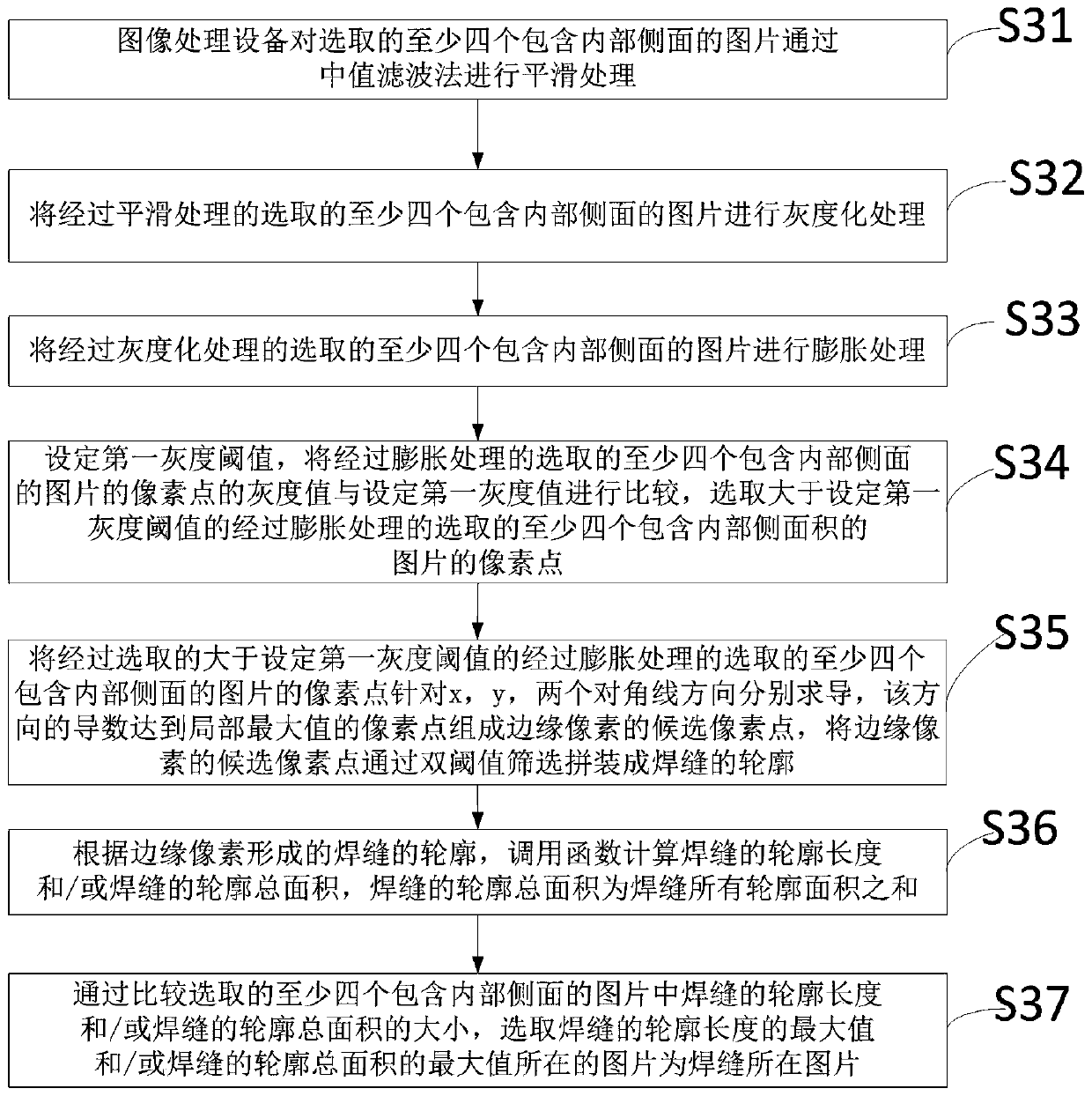

[0059] Such as image 3 As shown, step S3 in the technical solution of the present invention based on a method for automatic identification of square pipe weld positions specifically includes:

[0060] S31. The image processing device performs smoothing processing on at least four selected pictures containing internal sides by a median filter method;

[0061] S32. Perform grayscale processing on at least four smoothed selected pictures including interior sides;

[0062] S33, performing dilation processing on at least four selected images including the inner sides after the grayscale processing;

[0063] S34, setting the first grayscale threshold, comparing the grayscale values of at least four selected pixels of the picture including the inner side after the expansion process with the set first grayscale value, and selecting a value larger than the set first grayscale value Selected at least four pixel points of the picture containing the inner side after dilation processi...

Embodiment 3

[0078] Such as Figure 4 Shown, the present invention also provides a kind of method based on the automatic identification of square pipe weld position, comprising:

[0079] S1, the image acquisition device collects and saves the picture of the cross section of the square tube;

[0080] S2, the image processing device divides the collected pictures into nine equal parts and numbers them, and selects at least four pictures containing the inner sides and saves them respectively;

[0081] S3, the image processing device separately obtains the contour length and / or the total contour area of the weld in at least four selected pictures containing the internal side, according to the contour length and / or the total contour area of the weld in the picture Determine the number of the picture where the weld is located;

[0082] S4, according to the number of the picture where the weld is located, the angle of the weld of the square tube is judged according to the corresponding rule...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com