DMOS and manufacturing method of integrated starting tube, sampling tube and resistor

A manufacturing method and start-up tube technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of high loss and high cost, reduce start-up loss, reduce standby power consumption, and improve energy conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

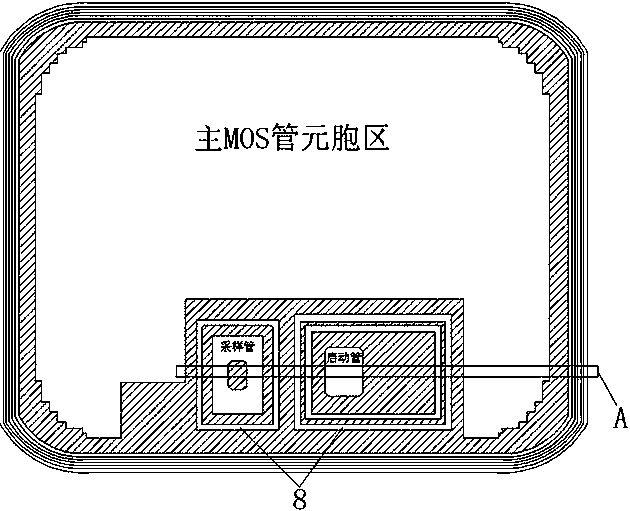

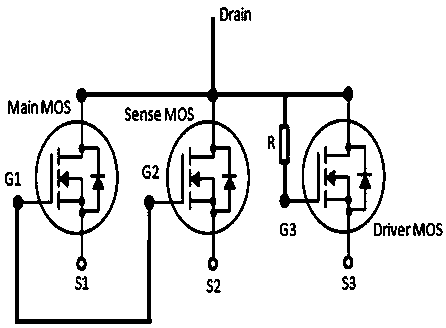

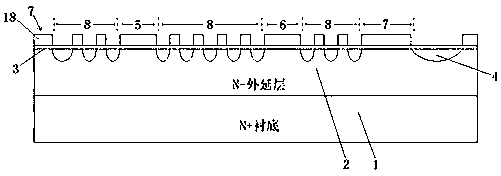

[0047] Such as Figures 1 to 12As shown, the embodiment of the present invention provides a DMOS integrating a startup transistor, a sampling transistor and a resistor, including a common substrate 1 and an epitaxial layer 2 disposed on the upper side of the substrate 1 . The substrate 1 adopts N-type (100) crystal orientation, is doped with arsenic element or antimony element, and the resistivity is usually less than 0.1Ω / cm. For ease of manufacture, the original thickness of the substrate 1 is preferably 625-675 μm. After the fabrication is completed, the substrate 1 needs to be reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com