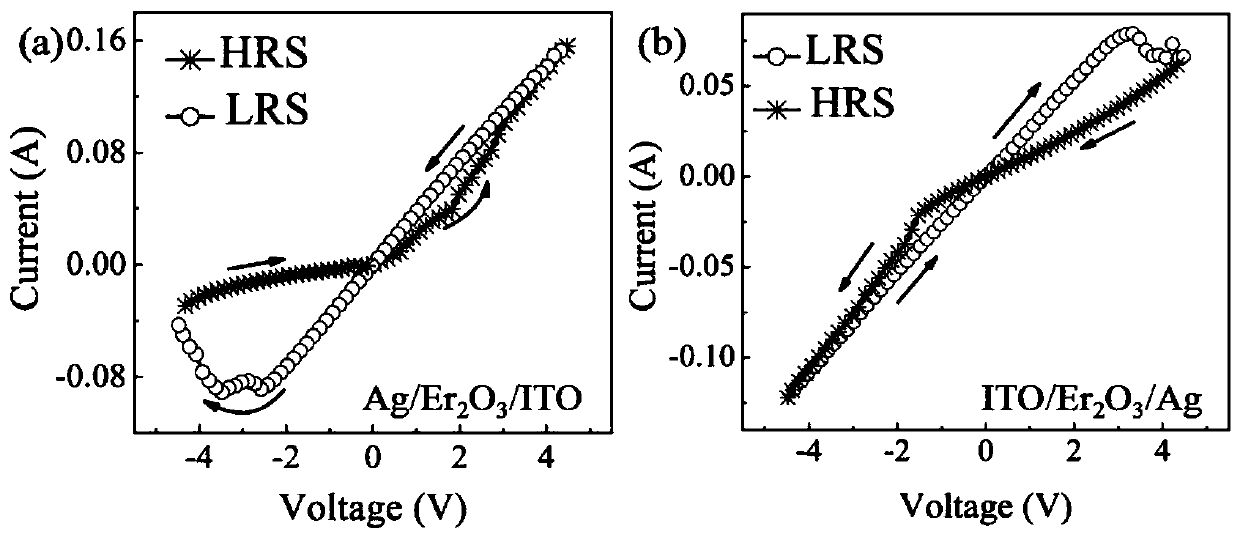

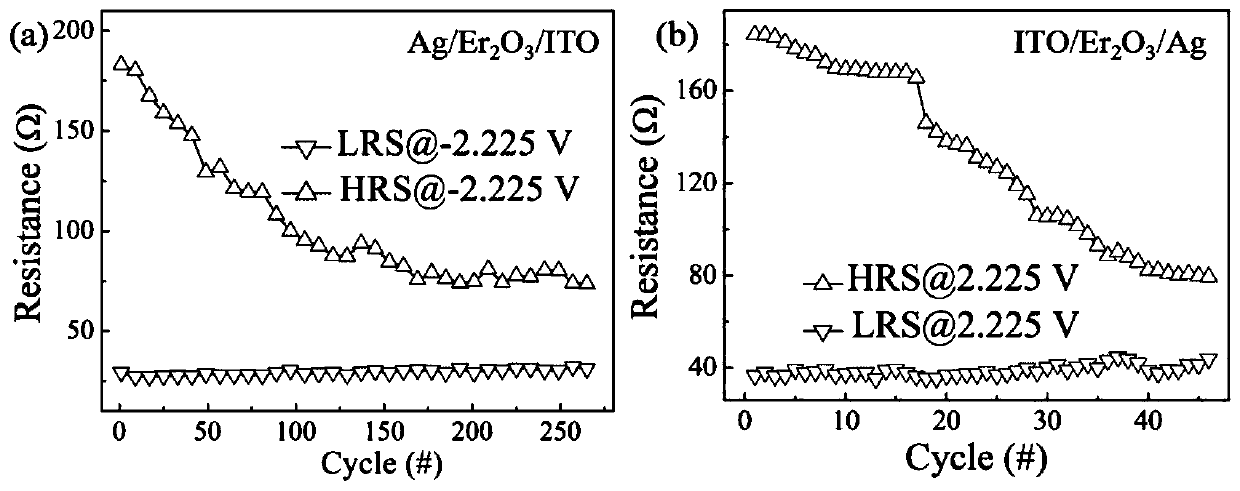

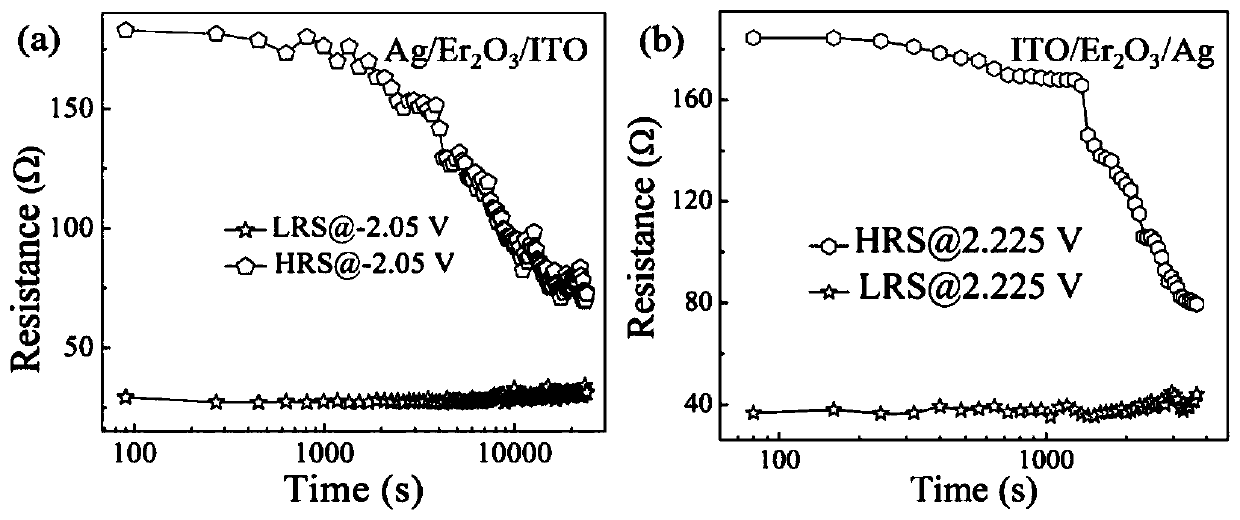

Memristor based on erbium oxide film and preparation method of memristor

A technology of erbium oxide and memristor, which is applied in the field of memristive device and its preparation based on erbium oxide thin film, achieving good application prospects, excellent performance and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0024] The preparation method of the memristive device of the present invention comprises the following steps:

[0025] S1. Cleaning the substrate: Put the substrate in deionized water, alcohol, acetone, alcohol, and deionized water in sequence, and ultrasonically clean it for 10-20 minutes respectively. After the substrate is dried, put it into the magnetron sputtering chamber;

[0026] S2. Prepare the bottom electrode: install the sputtering source of the bottom electrode in the magnetron sputtering chamber, that is, ITO or Ag target, set the distance from the target to the substrate to be 8-12 cm, and vacuum the sputtering chamber Draw to less than 5×10 -4 Pa, argon with a purity of 99.999% is introduced as the working gas, the sputtering pressure is 1.0-2.0Pa, the DC sputtering current is 0.2-0.3A, and the sputtering time is 10-20min;

[0027] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com