Potassium ion battery sulfur-doped mxene negative electrode material and preparation method thereof

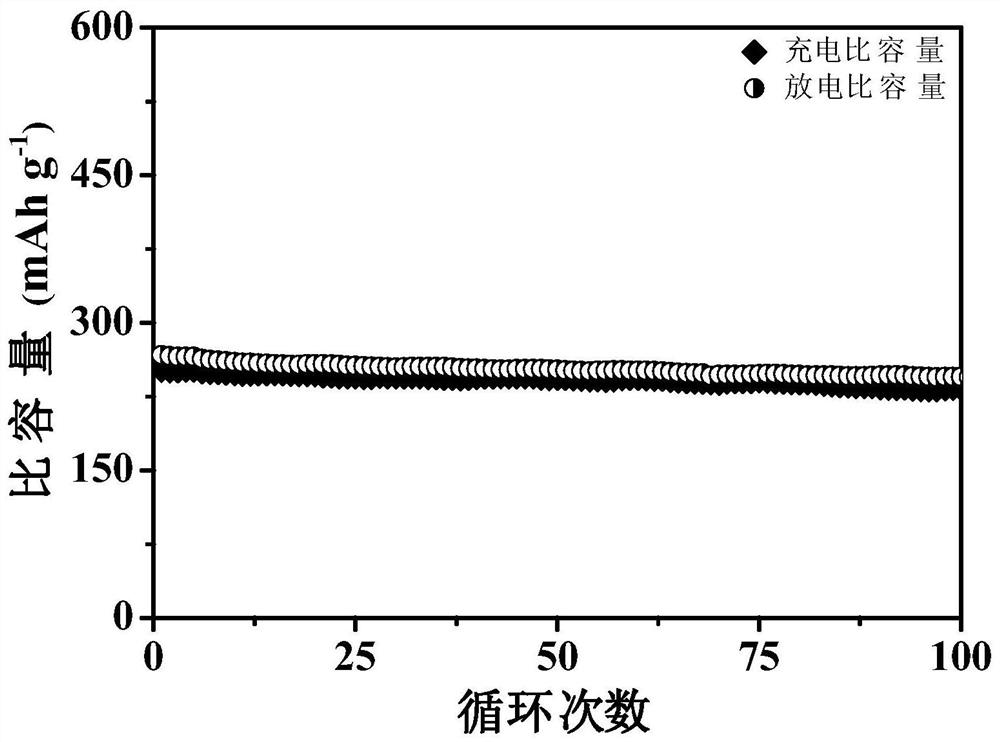

A negative electrode material, sulfur-doped technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as unsatisfactory performance, and achieve the effects of low cost, stable charge and discharge performance, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

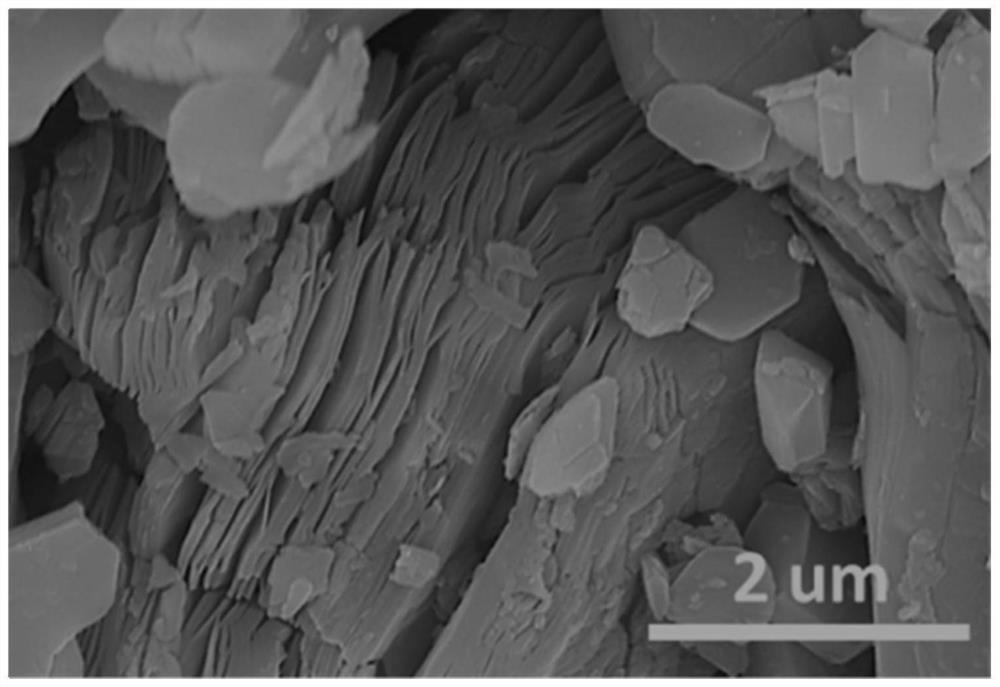

[0030] A preparation method of sulfur-doped MXene negative electrode material for potassium ion battery, comprising the following steps:

[0031] (1) Weigh 0.5g of V 2 CT x Add 0.5 g of dimethyl sulfone to deionized water, and magnetically stir for 4 hours to obtain a mixed solution;

[0032] (2) Move the mixed solution to the reaction kettle, move the reaction kettle to the oven and set the reaction temperature to 120°C and the reaction time to 12h, then cool to room temperature;

[0033] (3) The product obtained in step (2) was alternately washed 3 times with deionized water and ethanol, placed in a centrifuge for centrifugation at a speed of 3200r / min, and then vacuum-dried at 50°C for 12h;

[0034] (4) The product obtained in step (3) is heated up to 120° C. at a rate of 5° C. / min under a protective atmosphere of high-purity argon (purity ≥ 99.8%) at a gas flow rate of 150 ml / min, and kept at this temperature for 2 hour, cool down to room temperature to obtain the final...

Embodiment 2

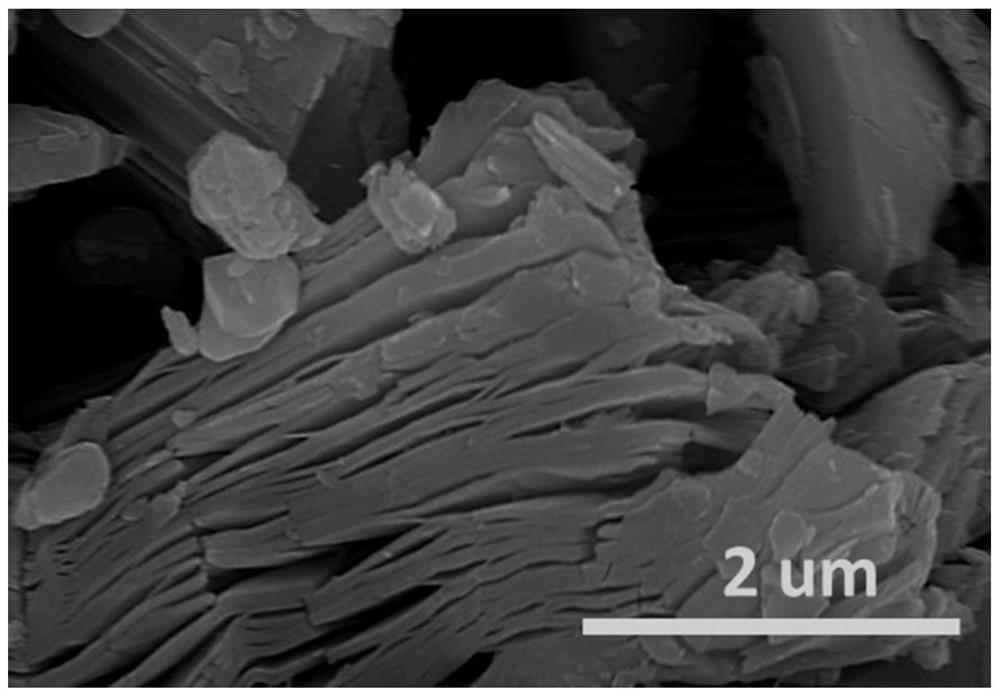

[0038] A preparation method of sulfur-doped MXene negative electrode material for potassium ion battery, comprising the following steps:

[0039] (1) Weigh 0.4g of V 2 CT x Add 4 g of dimethyl sulfone to deionized water, and magnetically stir for 6 hours to obtain a mixed solution;

[0040] (2) Move the mixed solution to the reaction kettle, move the reaction kettle to the oven and set the reaction temperature to 150°C and the reaction time to 15h, then cool to room temperature;

[0041] (3) The product obtained in step (2) was alternately washed 3 times with deionized water and ethanol, placed in a centrifuge for centrifugation at a speed of 3200r / min, and then vacuum-dried at 50°C for 12h;

[0042] (4) The product obtained in step (3) is heated up to 420° C. at a rate of 5° C. / min under a protective atmosphere of high-purity argon (purity ≥ 99.8%) at a gas flow rate of 150 ml / min, and kept at this temperature for 4 hour, cool down to room temperature to obtain the final s...

Embodiment 3

[0046] A preparation method of sulfur-doped MXene negative electrode material for potassium ion battery, comprising the following steps:

[0047] (1) Weigh 0.3g of V 2 CTx and 6g of dimethyl sulfone were added to deionized water, and magnetically stirred for 8 hours to obtain a mixed solution;

[0048] (2) Move the mixed solution to the reaction kettle, move the reaction kettle to the oven and set the reaction temperature to 200°C and the reaction time to 18h, then cool to room temperature;

[0049] (3) The product obtained in step (2) was alternately washed 3 times with deionized water and ethanol, placed in a centrifuge for centrifugation at a speed of 3200r / min, and then vacuum-dried at 50°C for 12h;

[0050] (4) The product obtained in step (3) is heated up to 700° C. at a rate of 5° C. / min under a protective atmosphere of high-purity argon (purity ≥ 99.8%) at a gas flow rate of 150 ml / min, and kept at this temperature for 6 hour, cool down to room temperature to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com